Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

ENGINE THROTTLE ADJUSTMENT TEST (continued)

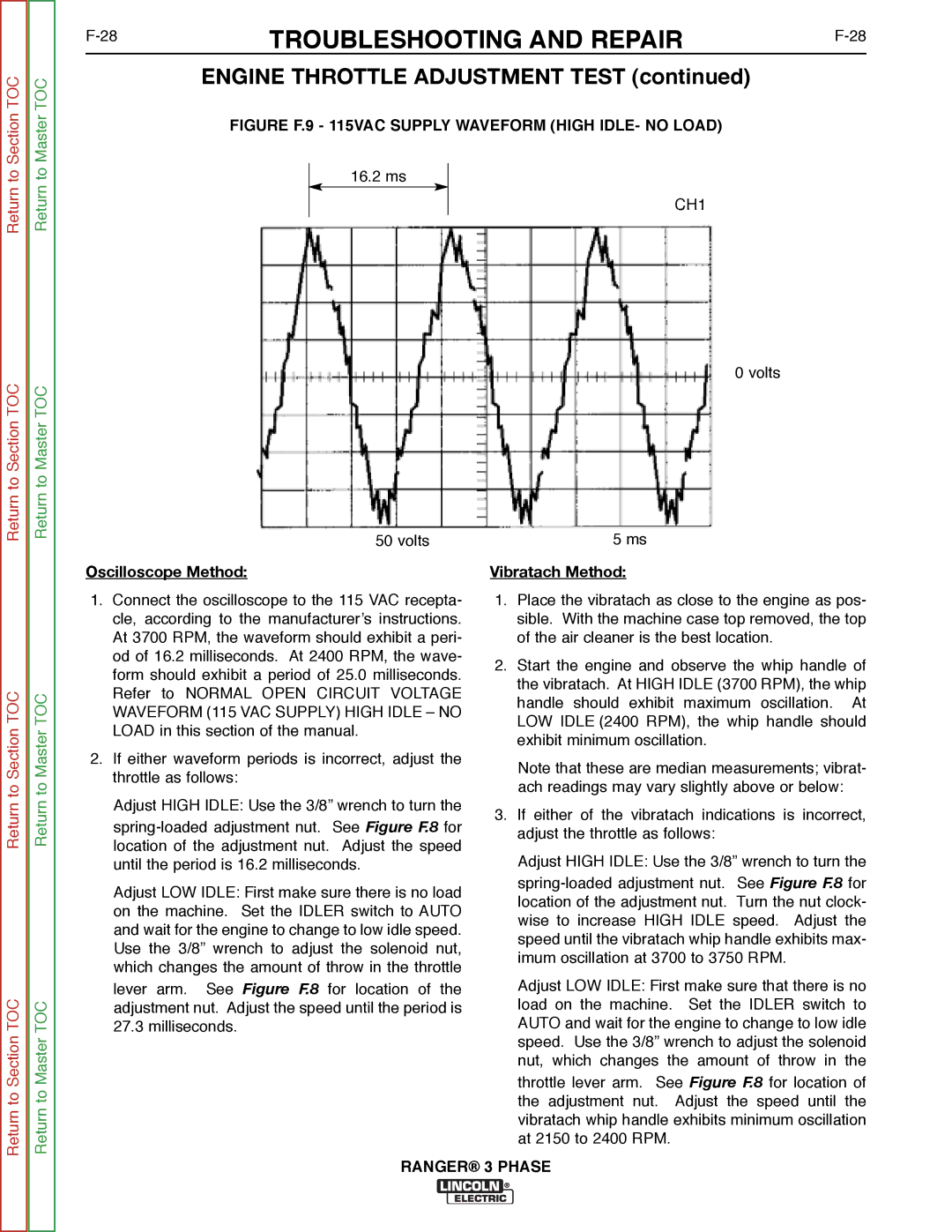

FIGURE F.9 - 115VAC SUPPLY WAVEFORM (HIGH IDLE- NO LOAD)

16.2 ms

CH1

0 volts

50 volts | 5 ms |

Oscilloscope Method: | Vibratach Method: |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1.Connect the oscilloscope to the 115 VAC recepta- cle, according to the manufacturer’s instructions. At 3700 RPM, the waveform should exhibit a peri- od of 16.2 milliseconds. At 2400 RPM, the wave- form should exhibit a period of 25.0 milliseconds. Refer to NORMAL OPEN CIRCUIT VOLTAGE WAVEFORM (115 VAC SUPPLY) HIGH IDLE – NO LOAD in this section of the manual.

2.If either waveform periods is incorrect, adjust the throttle as follows:

Adjust HIGH IDLE: Use the 3/8” wrench to turn the

Adjust LOW IDLE: First make sure there is no load on the machine. Set the IDLER switch to AUTO and wait for the engine to change to low idle speed. Use the 3/8” wrench to adjust the solenoid nut, which changes the amount of throw in the throttle lever arm. See Figure F.8 for location of the adjustment nut. Adjust the speed until the period is 27.3 milliseconds.

1.Place the vibratach as close to the engine as pos- sible. With the machine case top removed, the top of the air cleaner is the best location.

2.Start the engine and observe the whip handle of the vibratach. At HIGH IDLE (3700 RPM), the whip handle should exhibit maximum oscillation. At LOW IDLE (2400 RPM), the whip handle should exhibit minimum oscillation.

Note that these are median measurements; vibrat- ach readings may vary slightly above or below:

3.If either of the vibratach indications is incorrect, adjust the throttle as follows:

Adjust HIGH IDLE: Use the 3/8” wrench to turn the

Adjust LOW IDLE: First make sure that there is no load on the machine. Set the IDLER switch to AUTO and wait for the engine to change to low idle speed. Use the 3/8” wrench to adjust the solenoid nut, which changes the amount of throw in the throttle lever arm. See Figure F.8 for location of the adjustment nut. Adjust the speed until the vibratach whip handle exhibits minimum oscillation at 2150 to 2400 RPM.