Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

ENGINE/ROTOR REMOVAL AND REPLACEMENT PROCEDURE (cont.)

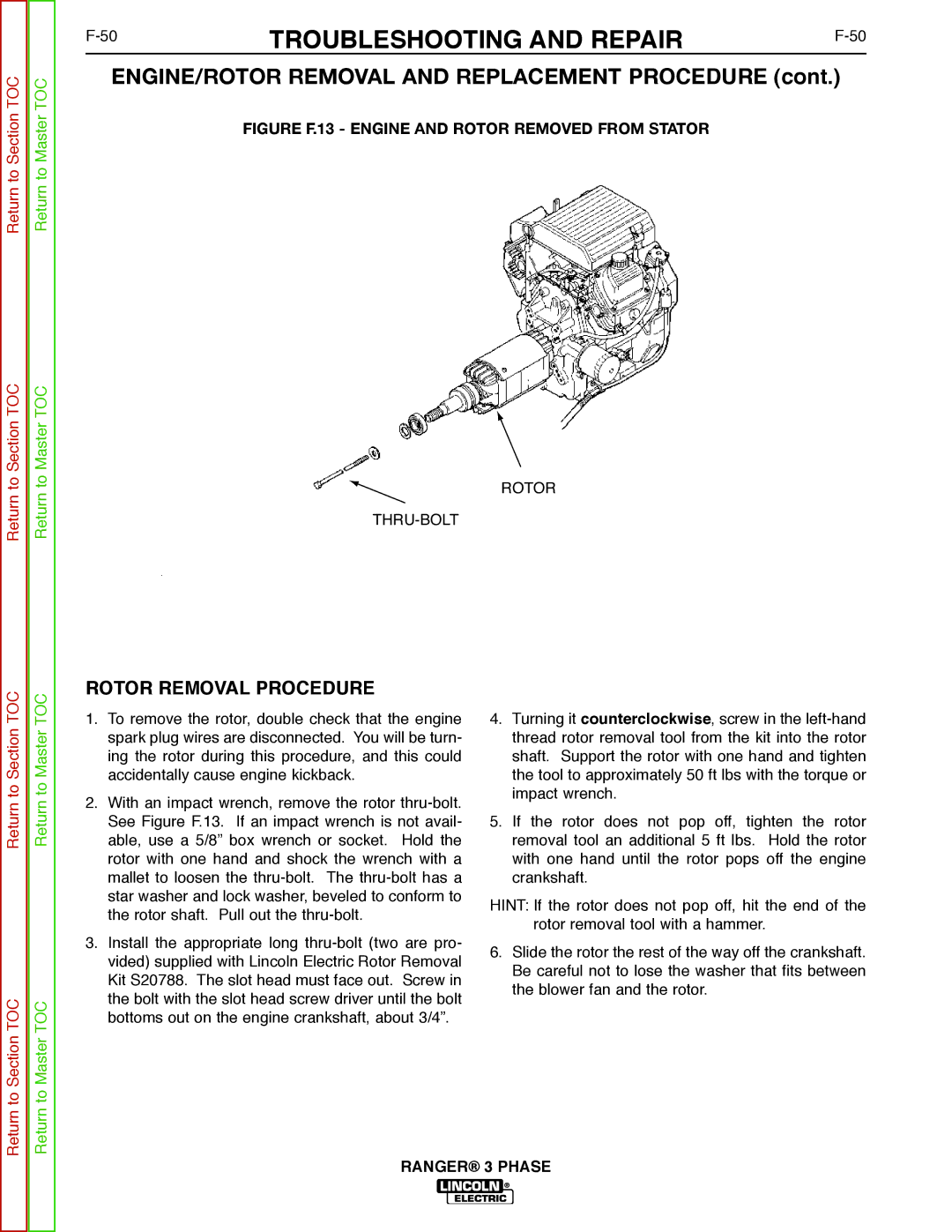

FIGURE F.13 - ENGINE AND ROTOR REMOVED FROM STATOR

ROTOR

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ROTOR REMOVAL PROCEDURE

1.To remove the rotor, double check that the engine spark plug wires are disconnected. You will be turn- ing the rotor during this procedure, and this could accidentally cause engine kickback.

2.With an impact wrench, remove the rotor

3.Install the appropriate long

4.Turning it counterclockwise, screw in the

5.If the rotor does not pop off, tighten the rotor removal tool an additional 5 ft lbs. Hold the rotor with one hand until the rotor pops off the engine crankshaft.

HINT: If the rotor does not pop off, hit the end of the rotor removal tool with a hammer.

6.Slide the rotor the rest of the way off the crankshaft. Be careful not to lose the washer that fits between the blower fan and the rotor.