OPERATION | ||

|

Return to Master TOC

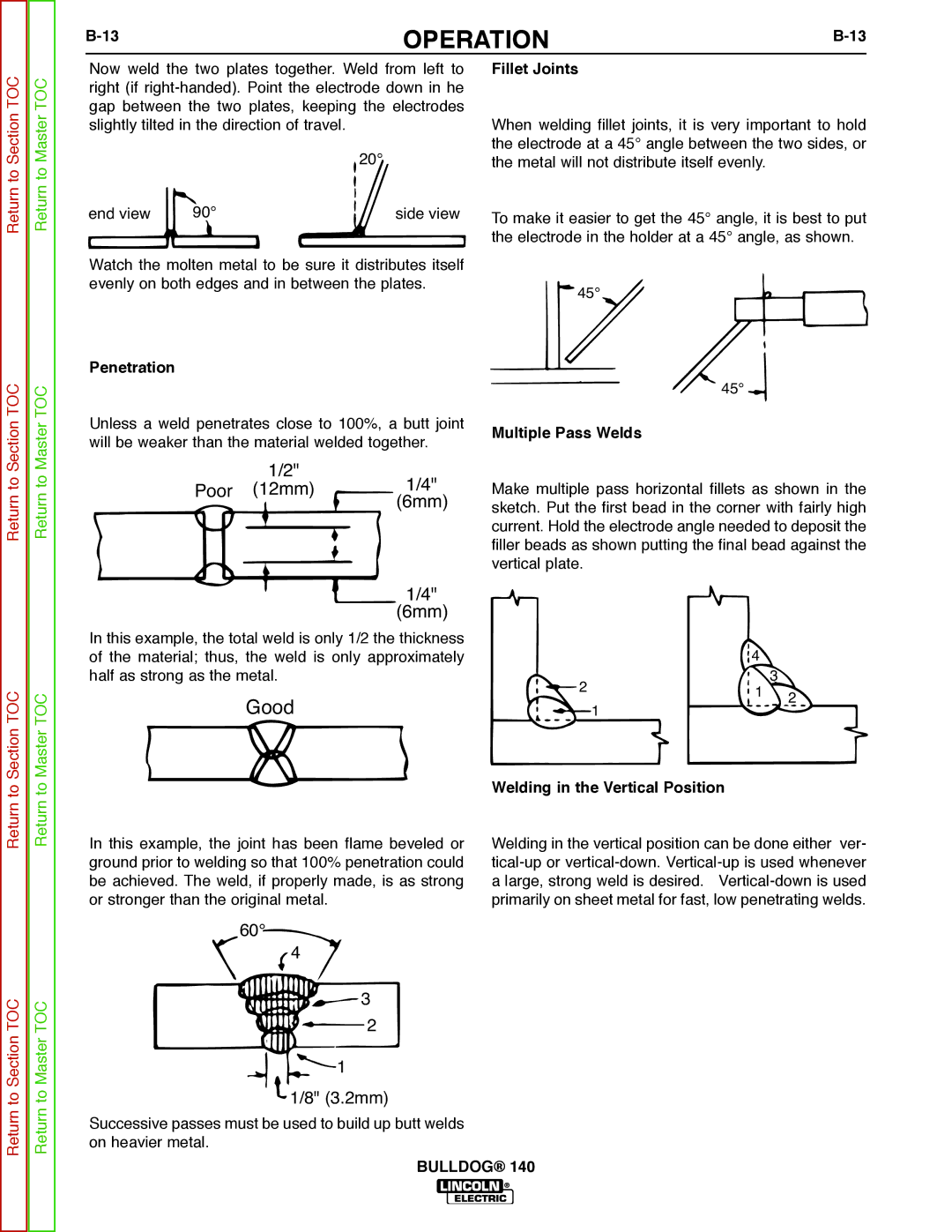

Now weld the two plates together. Weld from left to right (if

20°

end view | 90° | side view |

Fillet Joints

When welding fillet joints, it is very important to hold the electrode at a 45° angle between the two sides, or the metal will not distribute itself evenly.

To make it easier to get the 45° angle, it is best to put the electrode in the holder at a 45° angle, as shown.

Master TOC

Watch the molten metal to be sure it distributes itself evenly on both edges and in between the plates.

Penetration

Unless a weld penetrates close to 100%, a butt joint will be weaker than the material welded together.

45°

45° ![]()

Multiple Pass Welds

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

1/2"

Poor (12mm)1/4" (6mm)

1/4"

(6mm)

In this example, the total weld is only 1/2 the thickness of the material; thus, the weld is only approximately half as strong as the metal.

Good

Make multiple pass horizontal fillets as shown in the sketch. Put the first bead in the corner with fairly high current. Hold the electrode angle needed to deposit the filler beads as shown putting the final bead against the vertical plate.

| 4 | 3 |

2 | 1 | |

| 1 | 2 |

|

|

Welding in the Vertical Position

Return to Section TOC

Return to Master TOC

In this example, the joint has been flame beveled or | Welding in the vertical position can be done either ver- |

ground prior to welding so that 100% penetration could | |

be achieved. The weld, if properly made, is as strong | a large, strong weld is desired. |

or stronger than the original metal. | primarily on sheet metal for fast, low penetrating welds. |

60°

4

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 3

3 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 2

2

![]() 1

1

![]() 1/8" (3.2mm)

1/8" (3.2mm)

Successive passes must be used to build up butt welds on heavier metal.

BULLDOG® 140