OPERATION | ||

|

Return to Master TOC

4.The bead should be put on with a weaving motion, and it should be

| Work Table | Strike Arc |

| |

Brick | Here | Sharp Edge | ||

| ||||

|

| |||

|

|

|

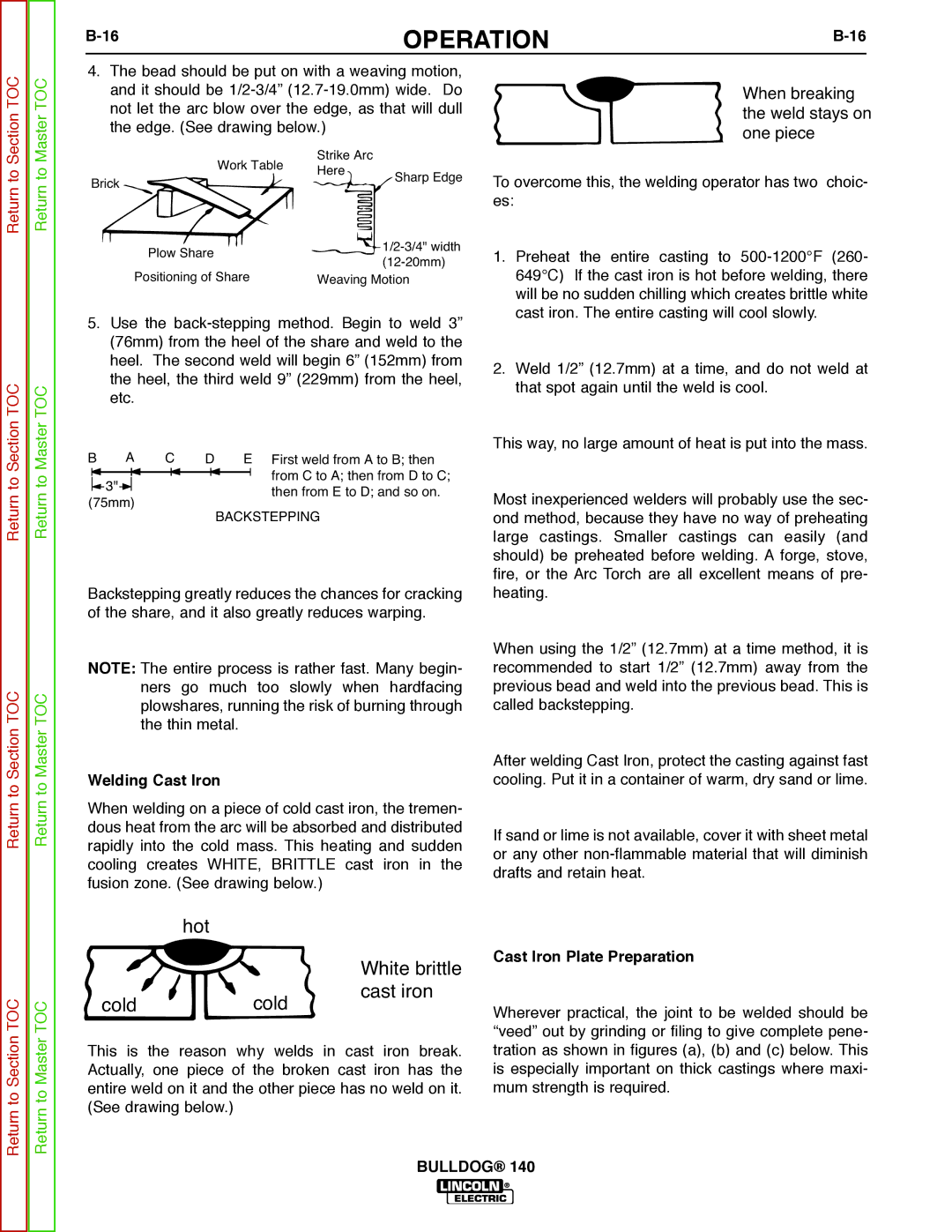

When breaking the weld stays on one piece

To overcome this, the welding operator has two choic- es:

TOC

Plow Share | ||

Positioning of Share | ||

Weaving Motion |

5.Use the

1.Preheat the entire casting to

2.Weld 1/2” (12.7mm) at a time, and do not weld at that spot again until the weld is cool.

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master

Return to Master TOC

B | A | C | D | E First weld from A to B; then | |||||

|

| 3" |

|

|

|

|

|

| from C to A; then from D to C; |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| then from E to D; and so on. | |

(75mm) |

|

|

|

|

| ||||

|

|

|

| BACKSTEPPING | |||||

|

|

|

|

|

|

|

| ||

Backstepping greatly reduces the chances for cracking of the share, and it also greatly reduces warping.

NOTE: The entire process is rather fast. Many begin- ners go much too slowly when hardfacing plowshares, running the risk of burning through the thin metal.

Welding Cast Iron

When welding on a piece of cold cast iron, the tremen- dous heat from the arc will be absorbed and distributed rapidly into the cold mass. This heating and sudden cooling creates WHITE, BRITTLE cast iron in the fusion zone. (See drawing below.)

This way, no large amount of heat is put into the mass.

Most inexperienced welders will probably use the sec- ond method, because they have no way of preheating large castings. Smaller castings can easily (and should) be preheated before welding. A forge, stove, fire, or the Arc Torch are all excellent means of pre- heating.

When using the 1/2” (12.7mm) at a time method, it is recommended to start 1/2” (12.7mm) away from the previous bead and weld into the previous bead. This is called backstepping.

After welding Cast Iron, protect the casting against fast cooling. Put it in a container of warm, dry sand or lime.

If sand or lime is not available, cover it with sheet metal or any other

Return to Section TOC

Return to Master TOC

| hot |

|

|

| White brittle |

cold | cold | cast iron |

|

This is the reason why welds in cast iron break. Actually, one piece of the broken cast iron has the entire weld on it and the other piece has no weld on it. (See drawing below.)

Cast Iron Plate Preparation

Wherever practical, the joint to be welded should be “veed” out by grinding or filing to give complete pene- tration as shown in figures (a), (b) and (c) below. This is especially important on thick castings where maxi- mum strength is required.

BULLDOG® 140