Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

INSTALLATION | |||

|

| ||

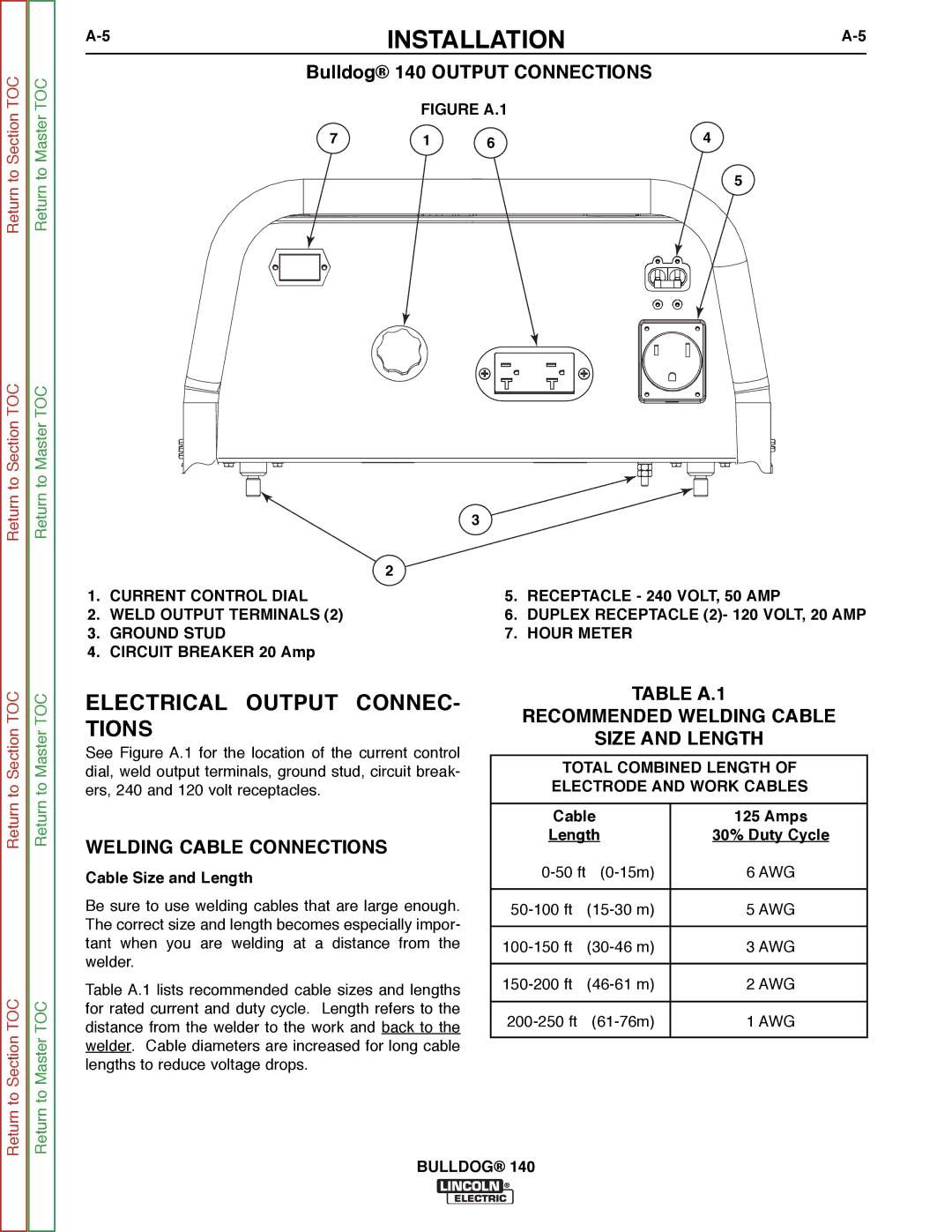

Bulldog® 140 OUTPUT CONNECTIONS |

| ||

| FIGURE A.1 |

| |

7 | 1 | 6 | 4 |

|

|

| 5 |

|

| 3 |

|

|

| 2 |

|

1. | CURRENT CONTROL DIAL | 5. | RECEPTACLE - 240 VOLT, 50 AMP |

2. | WELD OUTPUT TERMINALS (2) | 6. | DUPLEX RECEPTACLE (2)- 120 VOLT, 20 AMP |

3. | GROUND STUD | 7. | HOUR METER |

4. | CIRCUIT BREAKER 20 Amp |

|

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ELECTRICAL OUTPUT CONNEC- TIONS

See Figure A.1 for the location of the current control dial, weld output terminals, ground stud, circuit break- ers, 240 and 120 volt receptacles.

WELDING CABLE CONNECTIONS

Cable Size and Length

Be sure to use welding cables that are large enough. The correct size and length becomes especially impor- tant when you are welding at a distance from the welder.

Table A.1 lists recommended cable sizes and lengths for rated current and duty cycle. Length refers to the distance from the welder to the work and back to the welder. Cable diameters are increased for long cable lengths to reduce voltage drops.

TABLE A.1

RECOMMENDED WELDING CABLE

SIZE AND LENGTH

TOTAL COMBINED LENGTH OF

ELECTRODE AND WORK CABLES

Cable | 125 Amps | |

Length | 30% Duty Cycle | |

6 AWG | ||

|

|

|

5 AWG | ||

|

|

|

3 AWG | ||

|

|

|

2 AWG | ||

|

|

|

1 AWG | ||

|

|

|

BULLDOG® 140