MAINTENANCE | ||

|

Return to Master TOC

Return to Master TOC

SPARK PLUG SERVICE

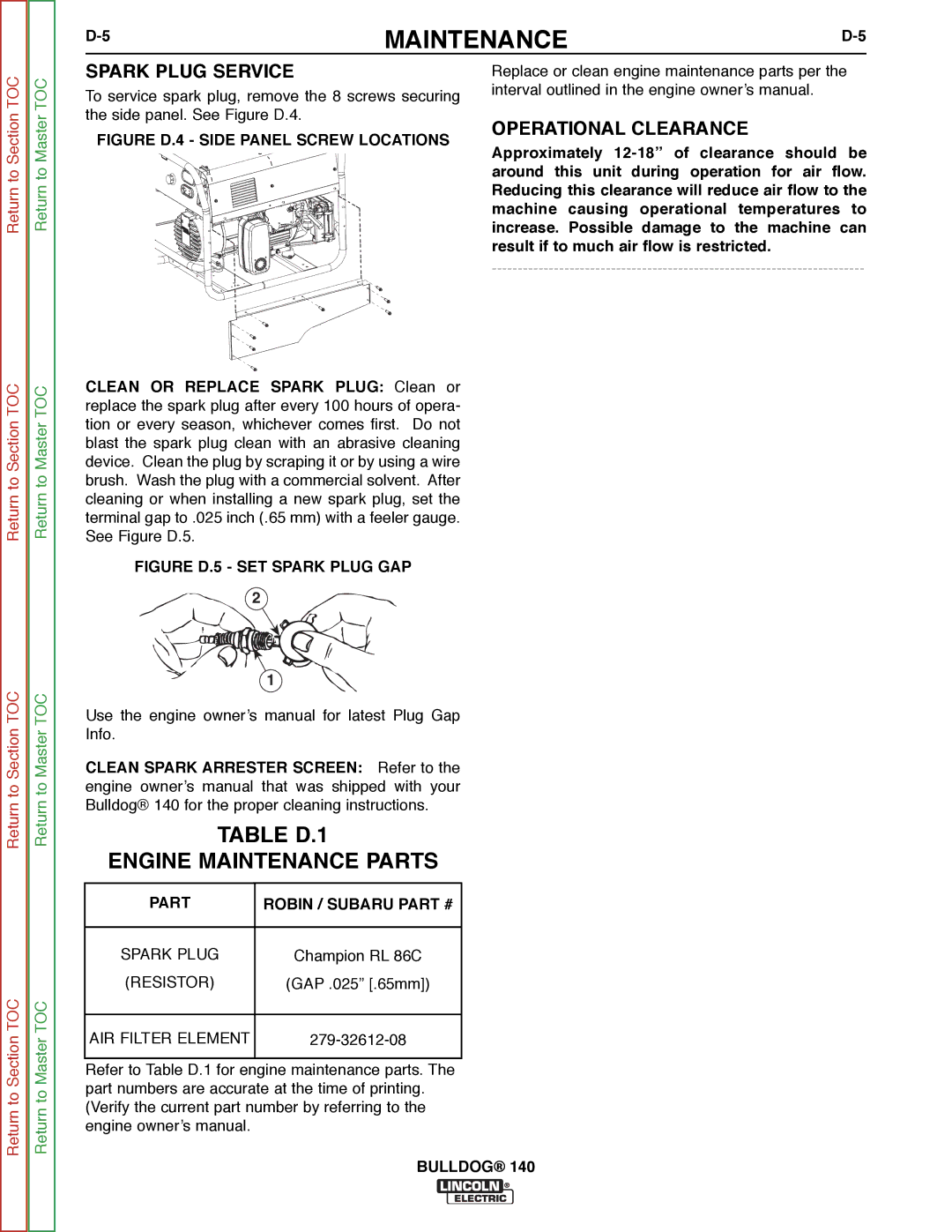

To service spark plug, remove the 8 screws securing the side panel. See Figure D.4.

FIGURE D.4 - SIDE PANEL SCREW LOCATIONS

CLEAN OR REPLACE SPARK PLUG: Clean or replace the spark plug after every 100 hours of opera- tion or every season, whichever comes first. Do not blast the spark plug clean with an abrasive cleaning device. Clean the plug by scraping it or by using a wire brush. Wash the plug with a commercial solvent. After cleaning or when installing a new spark plug, set the terminal gap to .025 inch (.65 mm) with a feeler gauge. See Figure D.5.

FIGURE D.5 - SET SPARK PLUG GAP

2

Replace or clean engine maintenance parts per the interval outlined in the engine owner’s manual.

OPERATIONAL CLEARANCE

Approximately

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

1

Use the engine owner’s manual for latest Plug Gap Info.

CLEAN SPARK ARRESTER SCREEN: Refer to the engine owner’s manual that was shipped with your Bulldog® 140 for the proper cleaning instructions.

TABLE D.1

ENGINE MAINTENANCE PARTS

PART | ROBIN / SUBARU PART # |

|

|

SPARK PLUG | Champion RL 86C |

(RESISTOR) | (GAP .025” [.65mm]) |

|

|

AIR FILTER ELEMENT | |

|

|

Refer to Table D.1 for engine maintenance parts. The part numbers are accurate at the time of printing. (Verify the current part number by referring to the engine owner’s manual.