4 Sidewall direct venting

Prepare wall penetrations

Installation & Operation Manual

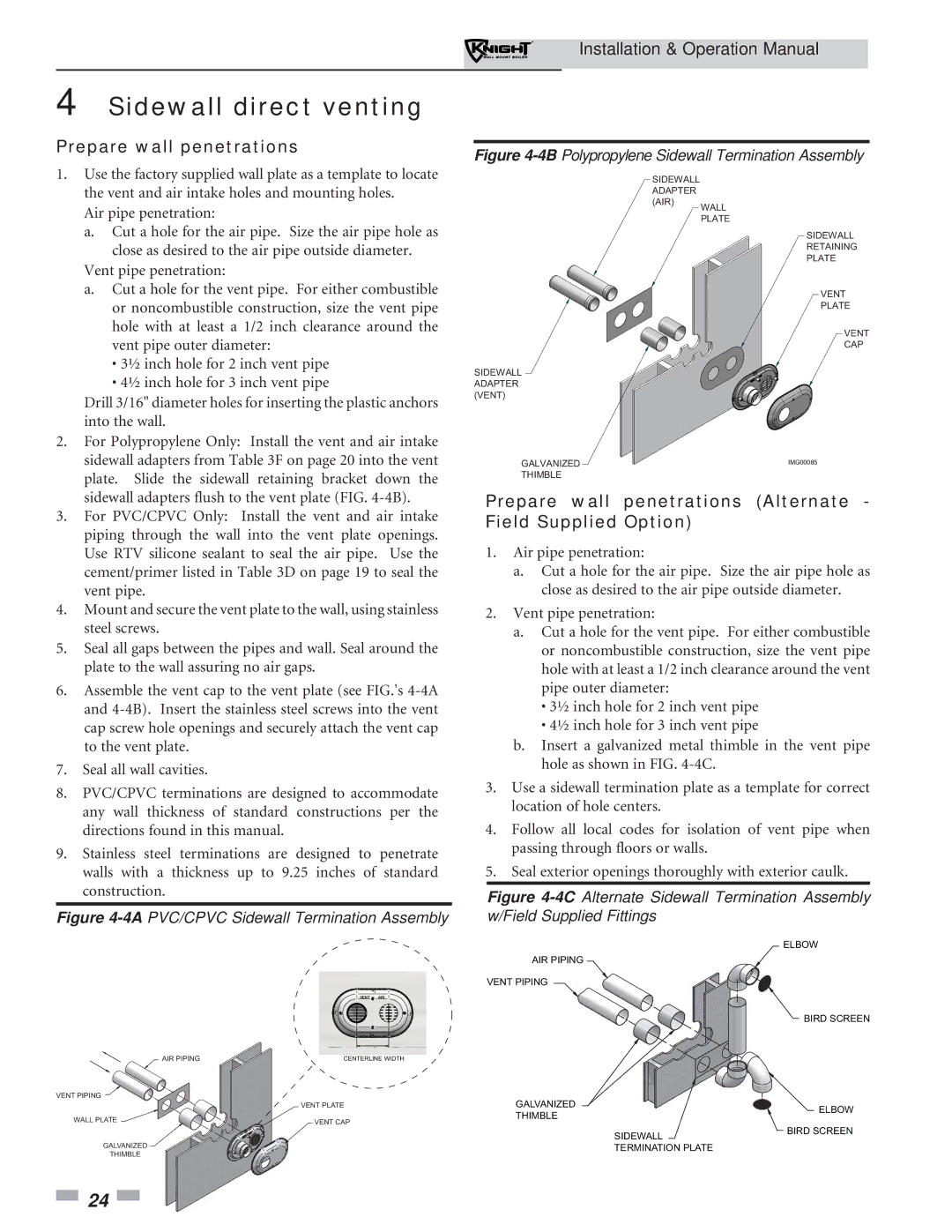

Figure 4-4B Polypropylene Sidewall Termination Assembly

1.Use the factory supplied wall plate as a template to locate the vent and air intake holes and mounting holes.

Air pipe penetration:

a.Cut a hole for the air pipe. Size the air pipe hole as close as desired to the air pipe outside diameter.

Vent pipe penetration:

a.Cut a hole for the vent pipe. For either combustible or noncombustible construction, size the vent pipe hole with at least a 1/2 inch clearance around the vent pipe outer diameter:

•3½ inch hole for 2 inch vent pipe

•4½ inch hole for 3 inch vent pipe

Drill 3/16" diameter holes for inserting the plastic anchors into the wall.

2. For Polypropylene Only: Install the vent and air intake |

sidewall adapters from Table 3F on page 20 into the vent |

plate. Slide the sidewall retaining bracket down the |

SIDEWALL ADAPTER (VENT)

GALVANIZED

THIMBLE

SIDEWALL

ADAPTER

(AIR)

WALL

PLATE

SIDEWALL

RETAINING

PLATE

VENT

PLATE

VENT

CAP

IMG00085

| sidewall adapters flush to the vent plate (FIG. |

3. | For PVC/CPVC Only: Install the vent and air intake |

| piping through the wall into the vent plate openings. |

| Use RTV silicone sealant to seal the air pipe. Use the |

| cement/primer listed in Table 3D on page 19 to seal the |

| vent pipe. |

4. | Mount and secure the vent plate to the wall, using stainless |

| steel screws. |

5. | Seal all gaps between the pipes and wall. Seal around the |

| plate to the wall assuring no air gaps. |

6. | Assemble the vent cap to the vent plate (see FIG.'s |

| and |

| cap screw hole openings and securely attach the vent cap |

| to the vent plate. |

7. | Seal all wall cavities. |

8. | PVC/CPVC terminations are designed to accommodate |

| any wall thickness of standard constructions per the |

| directions found in this manual. |

9. | Stainless steel terminations are designed to penetrate |

| walls with a thickness up to 9.25 inches of standard |

| construction. |

Figure 4-4A PVC/CPVC Sidewall Termination Assembly

VENT ![]() AIR

AIR

Prepare wall penetrations (Alternate - Field Supplied Option)

1.Air pipe penetration:

a.Cut a hole for the air pipe. Size the air pipe hole as close as desired to the air pipe outside diameter.

2.Vent pipe penetration:

a.Cut a hole for the vent pipe. For either combustible or noncombustible construction, size the vent pipe hole with at least a 1/2 inch clearance around the vent pipe outer diameter:

•3½ inch hole for 2 inch vent pipe

•4½ inch hole for 3 inch vent pipe

b.Insert a galvanized metal thimble in the vent pipe hole as shown in FIG.

3.Use a sidewall termination plate as a template for correct location of hole centers.

4.Follow all local codes for isolation of vent pipe when passing through floors or walls.

5.Seal exterior openings thoroughly with exterior caulk.

Figure 4-4C Alternate Sidewall Termination Assembly w/Field Supplied Fittings

ELBOW

AIR PIPING

VENT PIPING

BIRD SCREEN

AIR PIPING

VENT PIPING

WALL PLATE ![]()

GALVANIZED

THIMBLE

![]() 24

24 ![]()

CENTERLINE WIDTH

VENT PLATE

VENT CAP

GALVANIZED |

| ELBOW |

THIMBLE |

| |

|

| |

| SIDEWALL | BIRD SCREEN |

|

| |

| TERMINATION PLATE |

|