Installation & Operation Manual

6 Hydronic piping

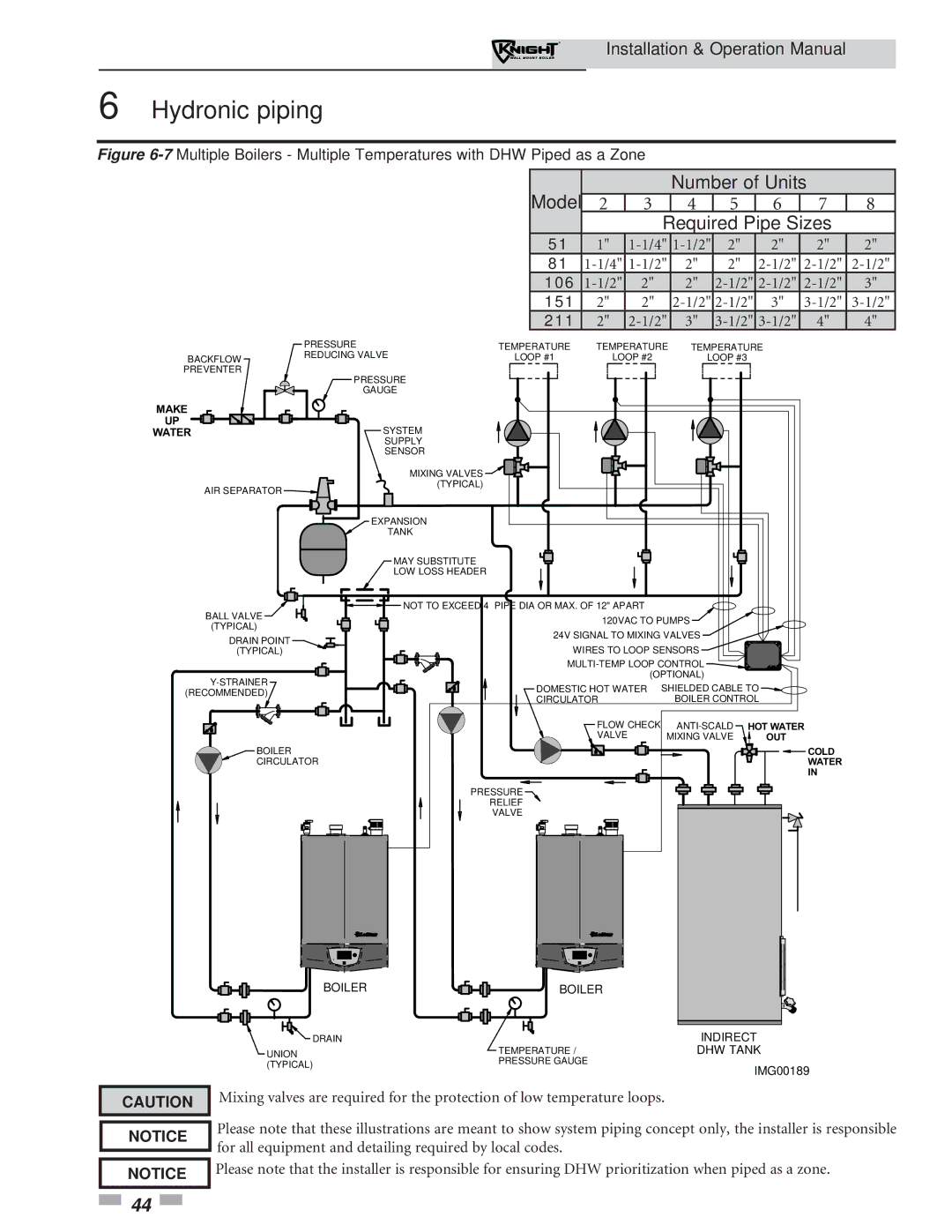

Figure 6-7 Multiple Boilers - Multiple Temperatures with DHW Piped as a Zone

Model |

|

| Number of Units |

| |||

2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|

| Required Pipe Sizes |

| ||||

51 | 1" | 2" | 2" | 2" | 2" | ||

81 | 2" | 2" | |||||

106 | 2" | 2" | 3" | ||||

151 | 2" | 2" | 3" | ||||

211 | 2" | 3" | 4" | 4" | |||

|

|

|

|

|

|

|

|

|

| PRESSURE | TEMPERATURE | TEMPERATURE | TEMPERATURE | |||||||||||||||

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||

BACKFLOW |

|

|

| REDUCING VALVE |

| LOOP #1 |

| LOOP #2 |

| LOOP #3 | ||||||||||||||||||

|

|

|

| |||||||||||||||||||||||||

PREVENTER |

|

|

|

| PRESSURE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| GAUGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MAKE |

|

UP | SYSTEM |

WATER | |

| SUPPLY |

| SENSOR |

MIXING VALVES ![]()

![]()

![]()

(TYPICAL)

AIR SEPARATOR ![]()

![]()

EXPANSION

TANK

MAY SUBSTITUTE

LOW LOSS HEADER

BALL VALVE |

(TYPICAL) |

DRAIN POINT

(TYPICAL)

BOILER

CIRCULATOR

![]()

![]() NOT TO EXCEED 4 PIPE DIA OR MAX. OF 12" APART

NOT TO EXCEED 4 PIPE DIA OR MAX. OF 12" APART

120VAC TO PUMPS |

| |

24V SIGNAL TO MIXING VALVES |

| |

WIRES TO LOOP SENSORS |

| |

| ||

(OPTIONAL) |

| |

DOMESTIC HOT WATER | SHIELDED CABLE TO | |

CIRCULATOR | BOILER CONTROL | |

FLOW CHECK | HOT WATER | |

VALVE | MIXING VALVE | OUT |

COLD

WATER

IN

PRESSURE

RELIEF

VALVE

BOILER | BOILER |

|

DRAIN |

| INDIRECT |

UNION | TEMPERATURE / | DHW TANK |

(TYPICAL) | PRESSURE GAUGE | IMG00189 |

| ||

|

|

CAUTION

NOTICE

NOTICE

Mixing valves are required for the protection of low temperature loops.

Please note that these illustrations are meant to show system piping concept only, the installer is responsible for all equipment and detailing required by local codes.

Please note that the installer is responsible for ensuring DHW prioritization when piped as a zone.

![]() 44

44 ![]()