General Information

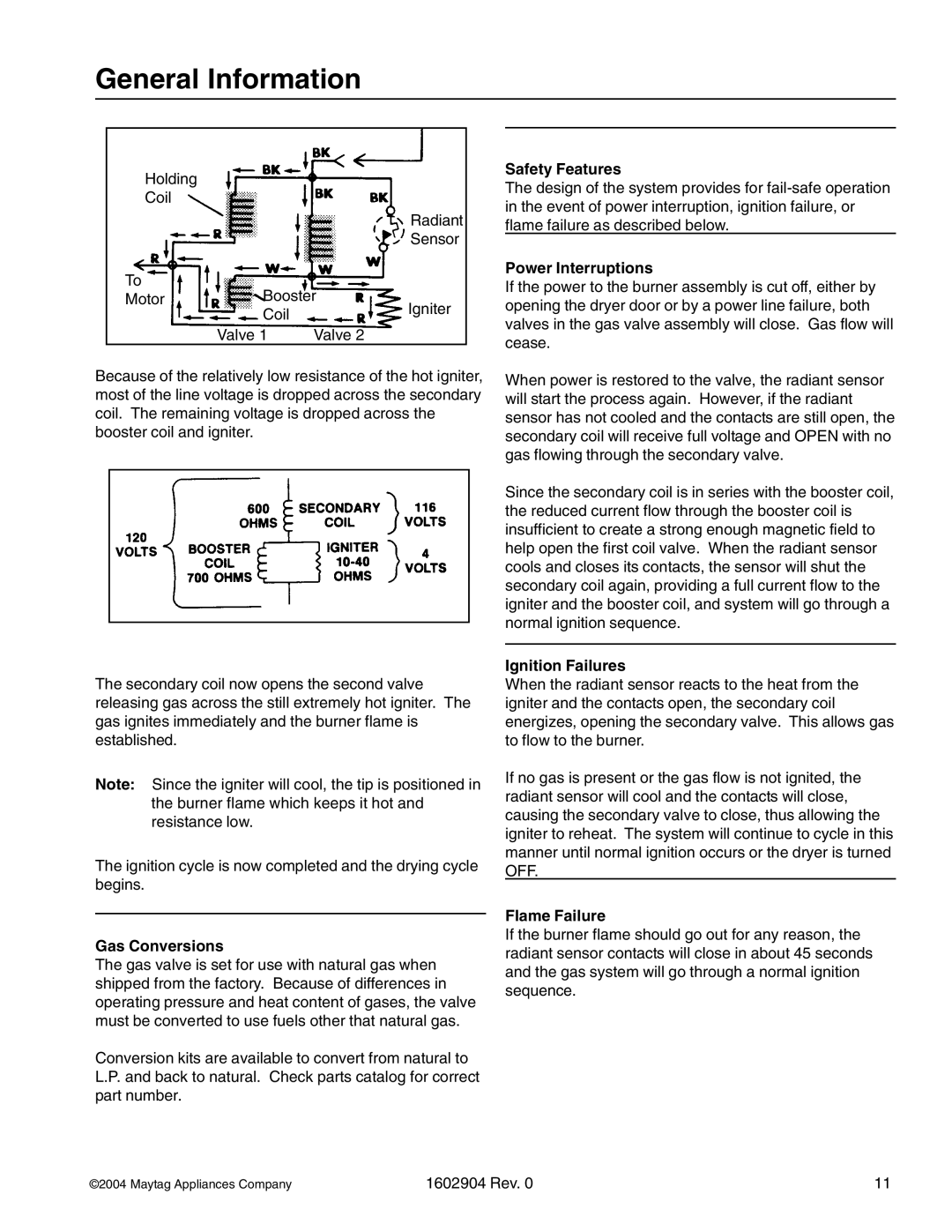

Holding

Coil

|

| Radiant |

|

| Sensor |

To | Booster | |

Motor | ||

| Coil | Igniter |

|

| |

| Valve 1 | Valve 2 |

Because of the relatively low resistance of the hot igniter, most of the line voltage is dropped across the secondary coil. The remaining voltage is dropped across the booster coil and igniter.

The secondary coil now opens the second valve releasing gas across the still extremely hot igniter. The gas ignites immediately and the burner flame is established.

Note: Since the igniter will cool, the tip is positioned in

the burner flame which keeps it hot and resistance low.

The ignition cycle is now completed and the drying cycle begins.

Gas Conversions

The gas valve is set for use with natural gas when shipped from the factory. Because of differences in operating pressure and heat content of gases, the valve must be converted to use fuels other that natural gas.

Conversion kits are available to convert from natural to L.P. and back to natural. Check parts catalog for correct part number.

Safety Features

The design of the system provides for

Power Interruptions

If the power to the burner assembly is cut off, either by opening the dryer door or by a power line failure, both valves in the gas valve assembly will close. Gas flow will cease.

When power is restored to the valve, the radiant sensor will start the process again. However, if the radiant sensor has not cooled and the contacts are still open, the secondary coil will receive full voltage and OPEN with no gas flowing through the secondary valve.

Since the secondary coil is in series with the booster coil, the reduced current flow through the booster coil is insufficient to create a strong enough magnetic field to help open the first coil valve. When the radiant sensor cools and closes its contacts, the sensor will shut the secondary coil again, providing a full current flow to the igniter and the booster coil, and system will go through a normal ignition sequence.

Ignition Failures

When the radiant sensor reacts to the heat from the igniter and the contacts open, the secondary coil energizes, opening the secondary valve. This allows gas to flow to the burner.

If no gas is present or the gas flow is not ignited, the radiant sensor will cool and the contacts will close, causing the secondary valve to close, thus allowing the igniter to reheat. The system will continue to cycle in this manner until normal ignition occurs or the dryer is turned OFF.

Flame Failure

If the burner flame should go out for any reason, the radiant sensor contacts will close in about 45 seconds and the gas system will go through a normal ignition sequence.

©2004 Maytag Appliances Company | 1602904 Rev. 0 | 11 |