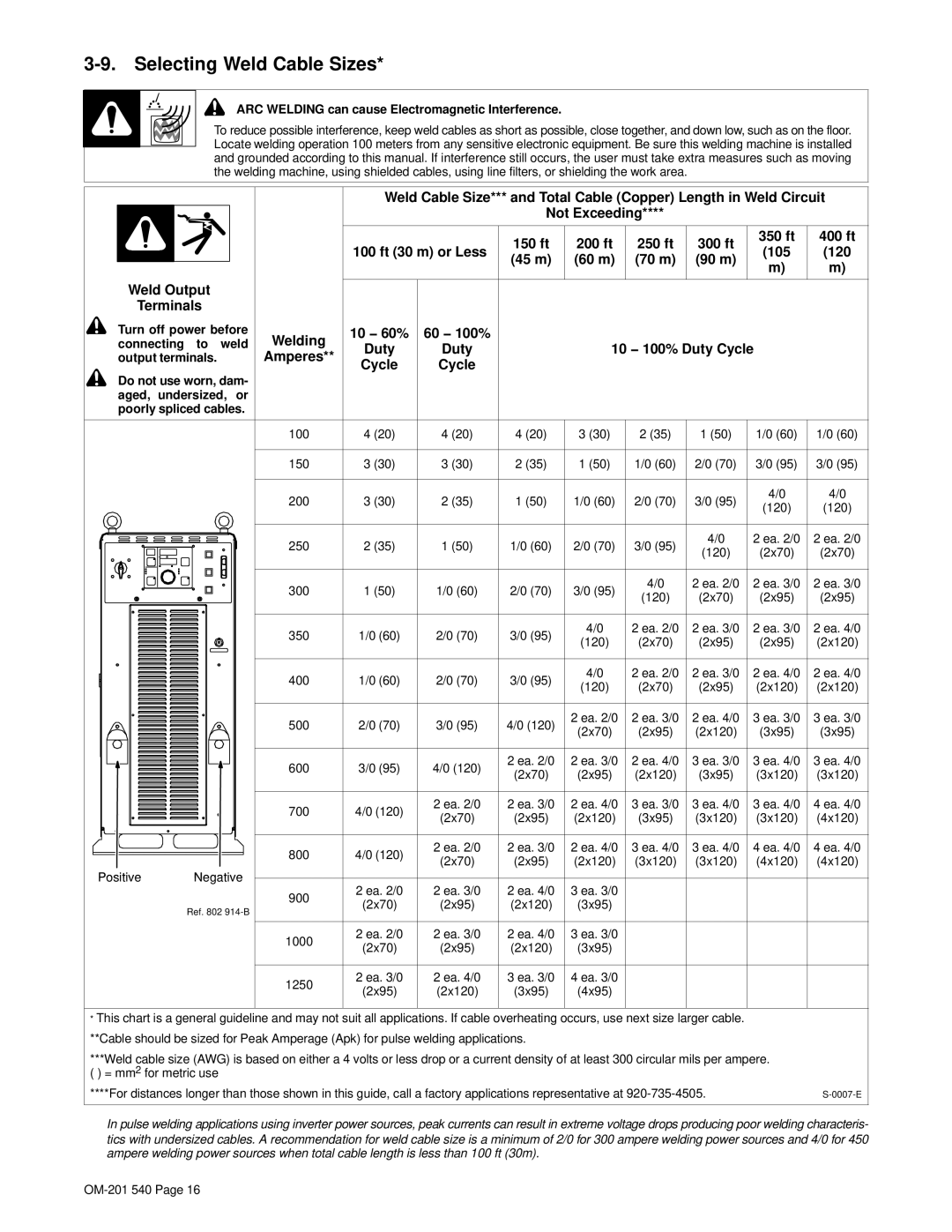

3-9. Selecting Weld Cable Sizes*

! ARC WELDING can cause Electromagnetic Interference.

! ARC WELDING can cause Electromagnetic Interference.

To reduce possible interference, keep weld cables as short as possible, close together, and down low, such as on the floor. Locate welding operation 100 meters from any sensitive electronic equipment. Be sure this welding machine is installed and grounded according to this manual. If interference still occurs, the user must take extra measures such as moving the welding machine, using shielded cables, using line filters, or shielding the work area.

|

| Weld Cable Size*** and Total Cable (Copper) Length in Weld Circuit | |||||||

|

|

|

| Not Exceeding**** |

|

|

| ||

|

|

|

| 150 ft | 200 ft | 250 ft | 300 ft | 350 ft | 400 ft |

|

| 100 ft (30 m) or Less | (105 | (120 | |||||

|

| (45 m) | (60 m) | (70 m) | (90 m) | ||||

|

|

|

| m) | m) | ||||

|

|

|

|

|

|

|

| ||

Weld Output |

|

|

|

|

|

|

|

|

|

Terminals |

|

|

|

|

|

|

|

|

|

! Turn off power before | Welding | 10 − 60% | 60 − 100% |

|

|

|

|

|

|

connecting to weld | Duty | Duty |

| 10 − 100% Duty Cycle |

|

| |||

output terminals. | Amperes** |

|

|

| |||||

Cycle | Cycle |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

!Do not use worn, dam- aged, undersized, or poorly spliced cables.

|

| 100 | 4 (20) | 4 (20) | 4 (20) | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 1/0 (60) |

|

| 150 | 3 (30) | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 3/0 (95) |

|

| 200 | 3 (30) | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 | 4/0 |

|

| (120) | (120) | |||||||

|

|

|

|

|

|

|

|

| ||

|

| 250 | 2 (35) | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 | 2 ea. 2/0 | 2 ea. 2/0 |

|

| (120) | (2x70) | (2x70) | ||||||

|

|

|

|

|

|

|

| |||

|

| 300 | 1 (50) | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 3/0 |

|

| (120) | (2x70) | (2x95) | (2x95) | |||||

|

|

|

|

|

|

| ||||

|

| 350 | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 3/0 | 2 ea. 4/0 |

|

| (120) | (2x70) | (2x95) | (2x95) | (2x120) | ||||

|

|

|

|

|

| |||||

|

| 400 | 1/0 (60) | 2/0 (70) | 3/0 (95) | 4/0 | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 2 ea. 4/0 |

|

| (120) | (2x70) | (2x95) | (2x120) | (2x120) | ||||

|

|

|

|

|

| |||||

|

| 500 | 2/0 (70) | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 | 3 ea. 3/0 |

|

| (2x70) | (2x95) | (2x120) | (3x95) | (3x95) | ||||

|

|

|

|

|

| |||||

|

| 600 | 3/0 (95) | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 | 3 ea. 4/0 | 3 ea. 4/0 |

|

| (2x70) | (2x95) | (2x120) | (3x95) | (3x120) | (3x120) | |||

|

|

|

|

| ||||||

|

| 700 | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 | 3 ea. 4/0 | 3 ea. 4/0 | 4 ea. 4/0 |

|

| (2x70) | (2x95) | (2x120) | (3x95) | (3x120) | (3x120) | (4x120) | ||

|

|

|

| |||||||

|

| 800 | 4/0 (120) | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 4/0 | 3 ea. 4/0 | 4 ea. 4/0 | 4 ea. 4/0 |

|

| (2x70) | (2x95) | (2x120) | (3x120) | (3x120) | (4x120) | (4x120) | ||

|

|

|

| |||||||

Positive | Negative |

| 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 |

|

|

|

|

) | * | 900 |

|

|

|

| ||||

|

| (2x70) | (2x95) | (2x120) | (3x95) |

|

|

|

| |

| Ref. 802 |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |

|

| 1000 | 2 ea. 2/0 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 |

|

|

|

|

|

| (2x70) | (2x95) | (2x120) | (3x95) |

|

|

|

| |

|

|

|

|

|

|

| ||||

|

| 1250 | 2 ea. 3/0 | 2 ea. 4/0 | 3 ea. 3/0 | 4 ea. 3/0 |

|

|

|

|

|

| (2x95) | (2x120) | (3x95) | (4x95) |

|

|

|

| |

|

|

|

|

|

|

|

*This chart is a general guideline and may not suit all applications. If cable overheating occurs, use next size larger cable. **Cable should be sized for Peak Amperage (Apk) for pulse welding applications.

***Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm2 for metric use

****For distances longer than those shown in this guide, call a factory applications representative at |

.In pulse welding applications using inverter power sources, peak currents can result in extreme voltage drops producing poor welding characteris- tics with undersized cables. A recommendation for weld cable size is a minimum of 2/0 for 300 ampere welding power sources and 4/0 for 450 ampere welding power sources when total cable length is less than 100 ft (30m).