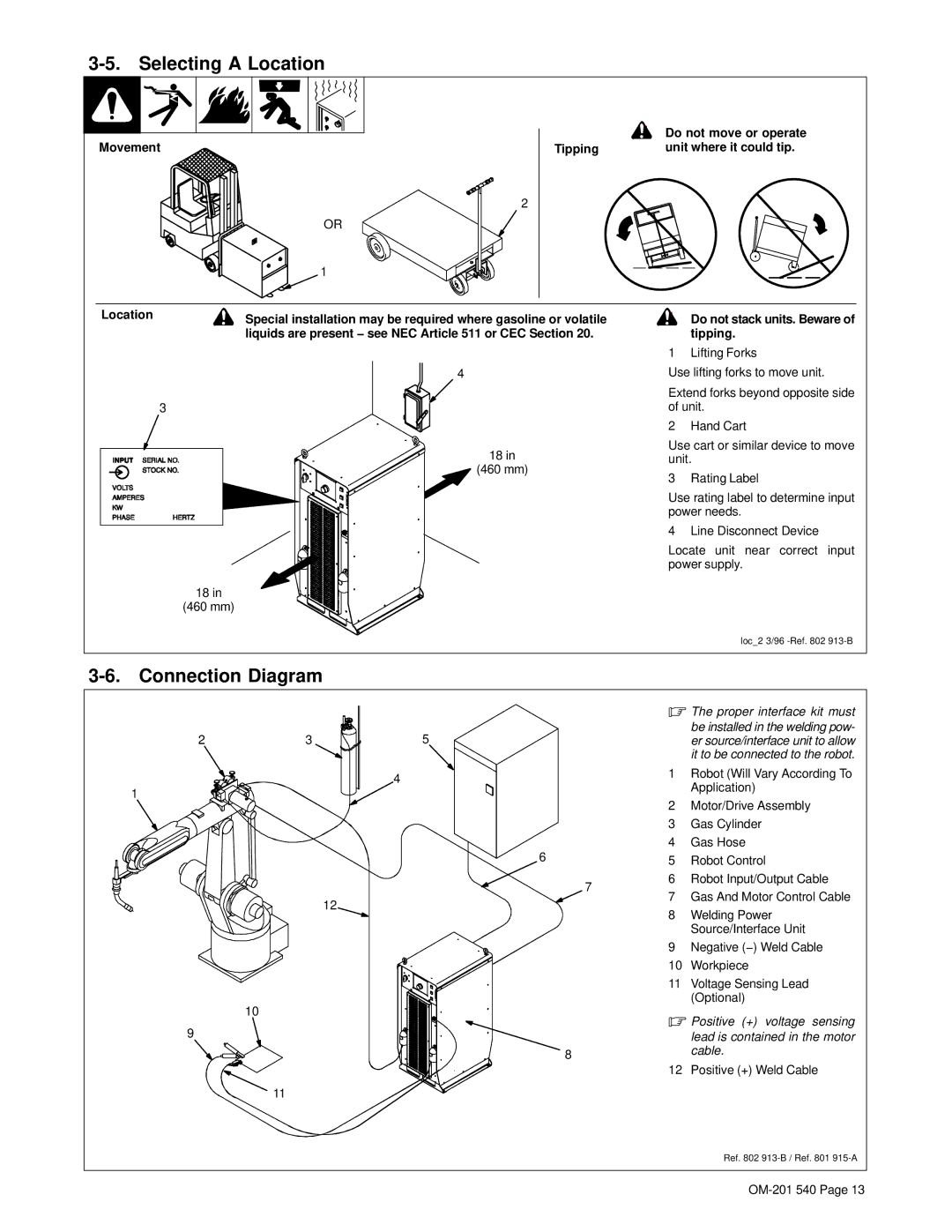

3-5. Selecting A Location

Movement

2

OR

1

| ! Do not move or operate |

Tipping | unit where it could tip. |

Location | ! Special installation may be required where gasoline or volatile |

| liquids are present − see NEC Article 511 or CEC Section 20. |

| 4 |

| 3 |

| 18 in |

| (460 mm) |

18 in

(460 mm)

! Do not stack units. Beware of tipping.

! Do not stack units. Beware of tipping.

1 Lifting Forks

Use lifting forks to move unit.

Extend forks beyond opposite side of unit.

2 Hand Cart

Use cart or similar device to move unit.

3 Rating Label

Use rating label to determine input power needs.

4 Line Disconnect Device

Locate unit near correct input power supply.

loc_2 3/96

3-6. Connection Diagram

23

1

12

10

9

11

5

4

6

7

8

.The proper interface kit must be installed in the welding pow- er source/interface unit to allow it to be connected to the robot.

1Robot (Will Vary According To Application)

2Motor/Drive Assembly

3Gas Cylinder

4Gas Hose

5Robot Control

6Robot Input/Output Cable

7Gas And Motor Control Cable

8Welding Power Source/Interface Unit

9Negative (−) Weld Cable

10Workpiece

11Voltage Sensing Lead (Optional)

.Positive (+) voltage sensing lead is contained in the motor cable.

12 Positive (+) Weld Cable

Ref. 802