.A complete Parts List is available

SECTION 6 − MAINTENANCE &TROUBLESHOOTING

6-1. Routine Maintenance

|

|

|

|

|

| Y Disconnect power | . Maintain more often |

|

|

|

|

|

| before maintaining. | during severe conditions. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n = Check | Z = Change | ~ = Clean | l = Replace |

* To be done by Factory Authorized Service Agent |

| ||

Every

3 Months

l Unreadable Labels | ~ Weld Terminals | nl Weld Cables |

Every

6![]() OR

OR

Months

~Inside Unit

Reference

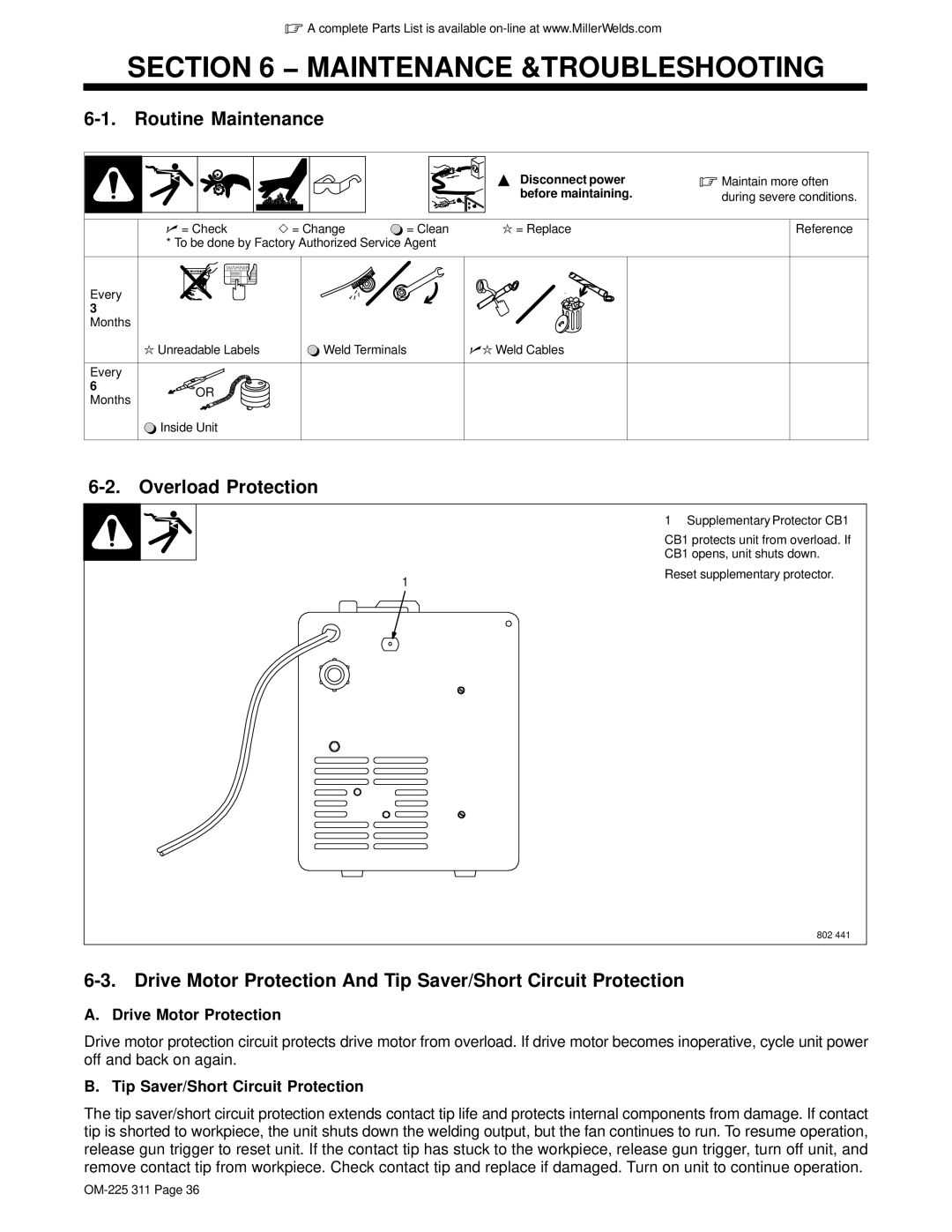

6-2. Overload Protection

1

1 Supplementary Protector CB1

CB1 protects unit from overload. If CB1 opens, unit shuts down.

Reset supplementary protector.

802 441

A. Drive Motor Protection

Drive motor protection circuit protects drive motor from overload. If drive motor becomes inoperative, cycle unit power off and back on again.

B. Tip Saver/Short Circuit Protection

The tip saver/short circuit protection extends contact tip life and protects internal components from damage. If contact tip is shorted to workpiece, the unit shuts down the welding output, but the fan continues to run. To resume operation, release gun trigger to reset unit. If the contact tip has stuck to the workpiece, release gun trigger, turn off unit, and remove contact tip from workpiece. Check contact tip and replace if damaged. Turn on unit to continue operation.