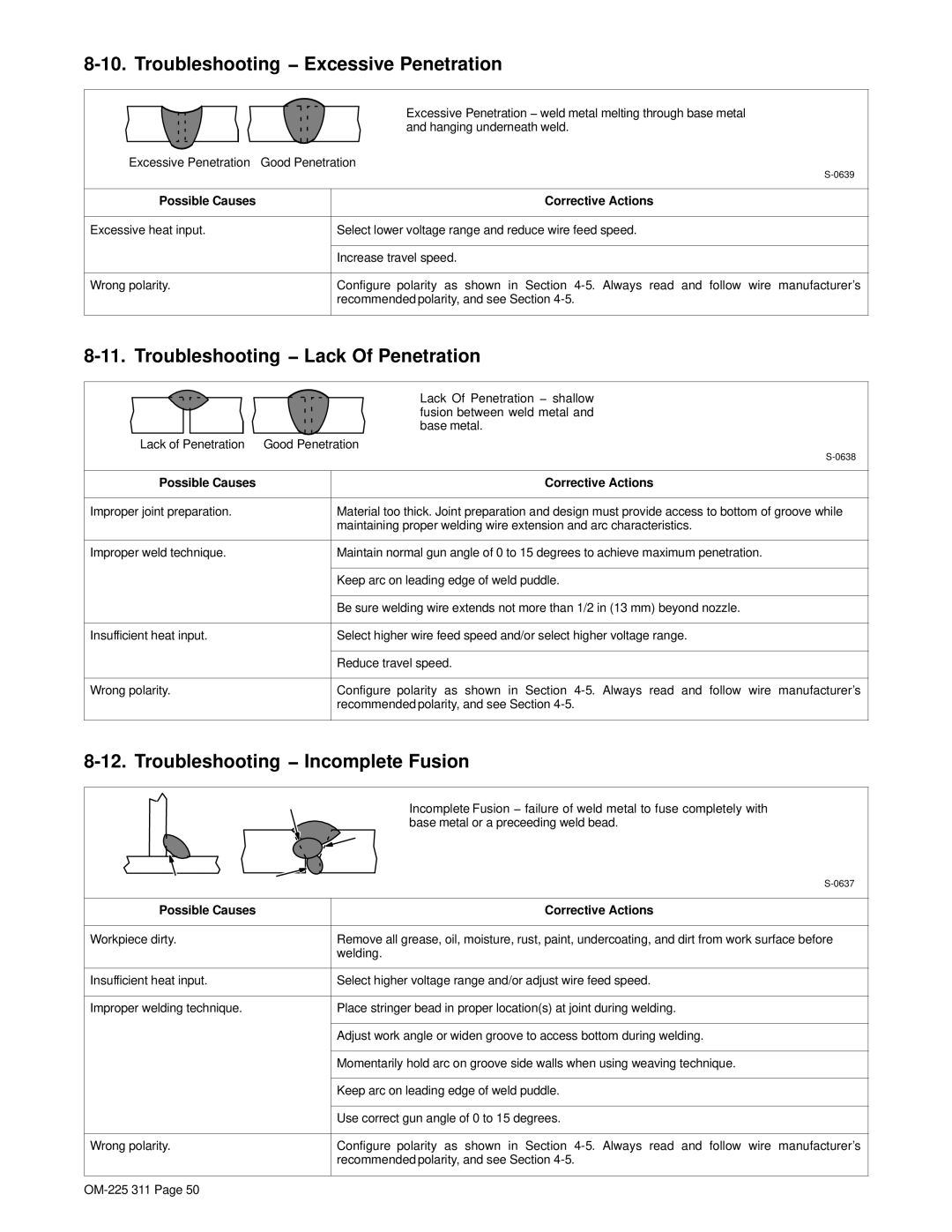

8-10. Troubleshooting − Excessive Penetration

|

|

|

| Excessive Penetration − weld metal melting through base metal |

|

|

|

| and hanging underneath weld. |

|

|

|

|

|

Excessive Penetration | Good Penetration | |||

|

|

|

| |

|

|

| ||

Possible Causes |

| Corrective Actions | ||

|

|

| ||

Excessive heat input. |

| Select lower voltage range and reduce wire feed speed. | ||

|

|

|

|

|

|

|

|

| Increase travel speed. |

|

|

| ||

Wrong polarity. |

| Configure polarity as shown in Section | ||

|

|

|

| recommended polarity, and see Section |

|

|

|

|

|

8-11. Troubleshooting − Lack Of Penetration

|

|

| Lack Of Penetration − shallow |

|

|

| fusion between weld metal and |

|

|

| |

|

|

| base metal. |

|

|

| |

Lack of Penetration | Good Penetration | ||

|

|

| |

|

| ||

Possible Causes | Corrective Actions | ||

|

| ||

Improper joint preparation. | Material too thick. Joint preparation and design must provide access to bottom of groove while | ||

|

|

| maintaining proper welding wire extension and arc characteristics. |

|

| ||

Improper weld technique. | Maintain normal gun angle of 0 to 15 degrees to achieve maximum penetration. | ||

| Keep arc on leading edge of weld puddle. |

|

|

| Be sure welding wire extends not more than 1/2 in (13 mm) beyond nozzle. |

|

|

Insufficient heat input. | Select higher wire feed speed and/or select higher voltage range. |

|

|

| Reduce travel speed. |

|

|

Wrong polarity. | Configure polarity as shown in Section |

| recommended polarity, and see Section |

8-12. Troubleshooting − Incomplete Fusion

Incomplete Fusion − failure of weld metal to fuse completely with base metal or a preceeding weld bead.

| |

|

|

Possible Causes | Corrective Actions |

|

|

Workpiece dirty. | Remove all grease, oil, moisture, rust, paint, undercoating, and dirt from work surface before |

| welding. |

|

|

Insufficient heat input. | Select higher voltage range and/or adjust wire feed speed. |

|

|

Improper welding technique. | Place stringer bead in proper location(s) at joint during welding. |

|

|

| Adjust work angle or widen groove to access bottom during welding. |

|

|

| Momentarily hold arc on groove side walls when using weaving technique. |

|

|

| Keep arc on leading edge of weld puddle. |

|

|

| Use correct gun angle of 0 to 15 degrees. |

|

|

Wrong polarity. | Configure polarity as shown in Section |

| recommended polarity, and see Section |

|

|

|

|