.A complete Parts List is available

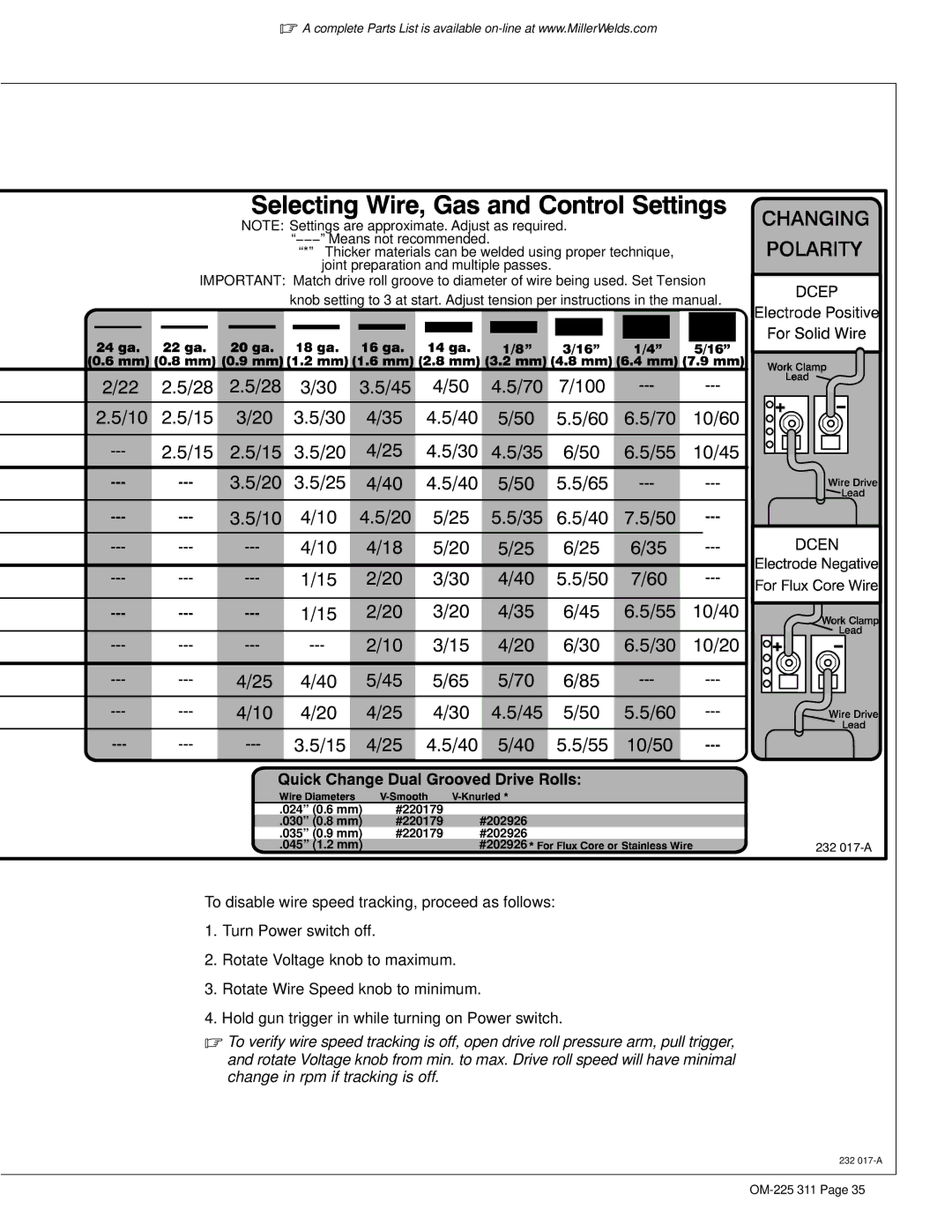

NOTE: Settings are approximate. Adjust as required. “−−−” Means not recommended.

“*” Thicker materials can be welded using proper technique, joint preparation and multiple passes.

IMPORTANT: Match drive roll groove to diameter of wire being used. Set Tension knob setting to 3 at start. Adjust tension per instructions in the manual.

2/22 | 2.5/28 | 2.5/28 | 3/30 | 3.5/45 | 4/50 | 4.5/70 | 7/100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.5/10 | 2.5/15 | 3/20 | 3.5/30 | 4/35 | 4.5/40 | 5/50 | 5.5/60 | 6.5/70 | 10/60 | |

|

|

|

|

|

|

|

|

|

|

|

| 2.5/15 | 2.5/15 | 3.5/20 | 4/25 | 4.5/30 | 4.5/35 | 6/50 | 6.5/55 | 10/45 | |

|

|

|

|

|

|

|

|

|

|

|

|

| 3.5/20 | 3.5/25 | 4/40 | 4.5/40 | 5/50 | 5.5/65 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3.5/10 | 4/10 | 4.5/20 | 5/25 | 5.5/35 | 6.5/40 | 7.5/50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4/10 | 4/18 | 5/20 | 5/25 | 6/25 | 6/35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/15 | 2/20 | 3/30 | 4/40 | 5.5/50 | 7/60 |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| 1/15 | 2/20 | 3/20 | 4/35 | 6/45 | 6.5/55 | 10/40 | |

|

|

|

|

|

|

|

|

|

| |

|

|

|

| 2/10 | 3/15 | 4/20 | 6/30 | 6.5/30 | 10/20 | |

|

|

|

|

|

|

|

|

|

|

|

|

| 4/25 | 4/40 | 5/45 | 5/65 | 5/70 | 6/85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4/10 | 4/20 | 4/25 | 4/30 | 4.5/45 | 5/50 | 5.5/60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3.5/15 | 4/25 | 4.5/40 | 5/40 | 5.5/55 | 10/50 |

|

|

.024” (0.6 mm) | #220179 |

|

|

|

|

.030” (0.8 mm) | #220179 | #202926 |

|

|

|

.035” (0.9 mm) | #220179 | #202926 |

|

|

|

.045” (1.2 mm) |

| #202926 |

|

| 232 |

|

|

| |||

|

|

|

To disable wire speed tracking, proceed as follows:

1.Turn Power switch off.

2.Rotate Voltage knob to maximum.

3.Rotate Wire Speed knob to minimum.

4.Hold gun trigger in while turning on Power switch.

.To verify wire speed tracking is off, open drive roll pressure arm, pull trigger, and rotate Voltage knob from min. to max. Drive roll speed will have minimal change in rpm if tracking is off.

232