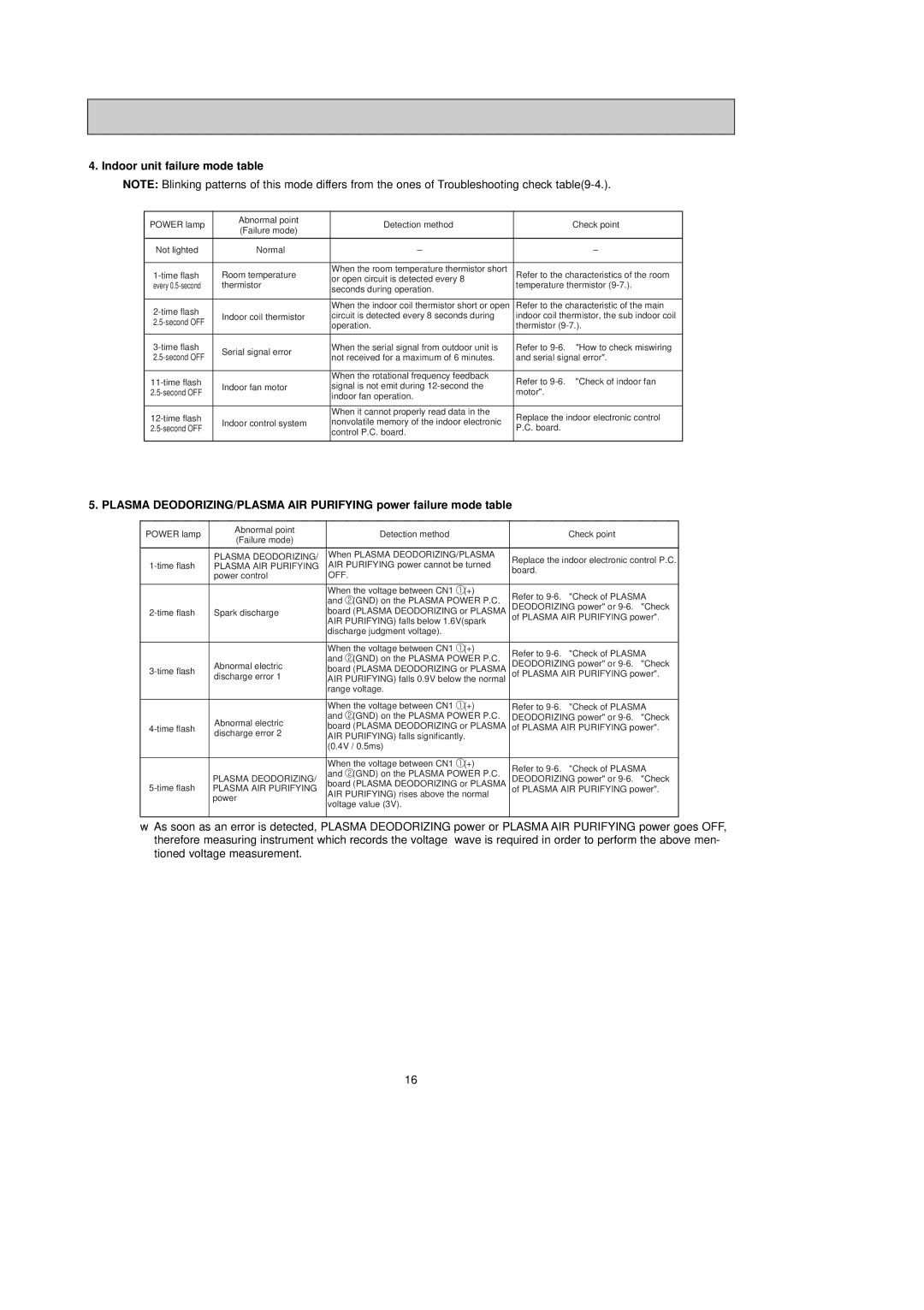

4. Indoor unit failure mode table

NOTE: Blinking patterns of this mode differs from the ones of Troubleshooting check

POWER lamp | Abnormal point | Detection method | Check point | |

(Failure mode) | ||||

|

|

| ||

|

|

|

| |

Not lighted | Normal | – | – | |

|

|

|

| |

Room temperature | When the room temperature thermistor short | Refer to the characteristics of the room | ||

every | thermistor | or open circuit is detected every 8 | temperature thermistor | |

seconds during operation. | ||||

|

|

| ||

|

|

|

| |

| When the indoor coil thermistor short or open | Refer to the characteristic of the main | ||

Indoor coil thermistor | circuit is detected every 8 seconds during | indoor coil thermistor, the sub indoor coil | ||

| operation. | thermistor | ||

|

| |||

|

|

|

| |

Serial signal error | When the serial signal from outdoor unit is | Refer to | ||

not received for a maximum of 6 minutes. | and serial signal error". | |||

| ||||

|

|

|

| |

| When the rotational frequency feedback | Refer to | ||

Indoor fan motor | signal is not emit during | |||

motor". | ||||

| indoor fan operation. | |||

|

|

| ||

|

|

|

| |

| When it cannot properly read data in the | Replace the indoor electronic control | ||

Indoor control system | nonvolatile memory of the indoor electronic | |||

P.C. board. | ||||

| control P.C. board. | |||

|

|

| ||

|

|

|

|

5. PLASMA DEODORIZING/PLASMA AIR PURIFYING power failure mode table

POWER lamp | Abnormal point | Detection method | Check point | |

(Failure mode) | ||||

|

|

| ||

|

|

|

| |

| PLASMA DEODORIZING/ | When PLASMA DEODORIZING/PLASMA | Replace the indoor electronic control P.C. | |

PLASMA AIR PURIFYING | AIR PURIFYING power cannot be turned | |||

board. | ||||

| power control | OFF. | ||

|

| |||

|

|

|

| |

|

| When the voltage between CN1 1(+) | Refer to | |

|

| and 2(GND) on the PLASMA POWER P.C. | ||

|

| DEODORIZING power" or | ||

Spark discharge | board (PLASMA DEODORIZING or PLASMA | |||

|

| AIR PURIFYING) falls below 1.6V(spark | of PLASMA AIR PURIFYING power". | |

|

|

| ||

|

| discharge judgment voltage). |

| |

|

|

|

| |

|

| When the voltage between CN1 1(+) | Refer to | |

|

| and 2(GND) on the PLASMA POWER P.C. | ||

| Abnormal electric | DEODORIZING power" or | ||

board (PLASMA DEODORIZING or PLASMA | ||||

discharge error 1 | AIR PURIFYING) falls 0.9V below the normal | of PLASMA AIR PURIFYING power". | ||

| ||||

|

| range voltage. |

| |

|

|

|

| |

|

| When the voltage between CN1 1(+) | Refer to | |

| Abnormal electric | and 2(GND) on the PLASMA POWER P.C. | DEODORIZING power" or | |

board (PLASMA DEODORIZING or PLASMA | of PLASMA AIR PURIFYING power". | |||

discharge error 2 | ||||

| AIR PURIFYING) falls significantly. |

| ||

|

|

| ||

|

| (0.4V / 0.5ms) |

| |

|

|

|

| |

|

| When the voltage between CN1 1(+) | Refer to | |

| PLASMA DEODORIZING/ | and 2(GND) on the PLASMA POWER P.C. | ||

| DEODORIZING power" or | |||

board (PLASMA DEODORIZING or PLASMA | ||||

PLASMA AIR PURIFYING | of PLASMA AIR PURIFYING power". | |||

| power | AIR PURIFYING) rises above the normal |

| |

| voltage value (3V). |

| ||

|

|

| ||

|

|

|

|

wAs soon as an error is detected, PLASMA DEODORIZING power or PLASMA AIR PURIFYING power goes OFF, therefore measuring instrument which records the voltage wave is required in order to perform the above men- tioned voltage measurement.

16