7. The putting condition of the belt.

(PE(H)-15,20 only)

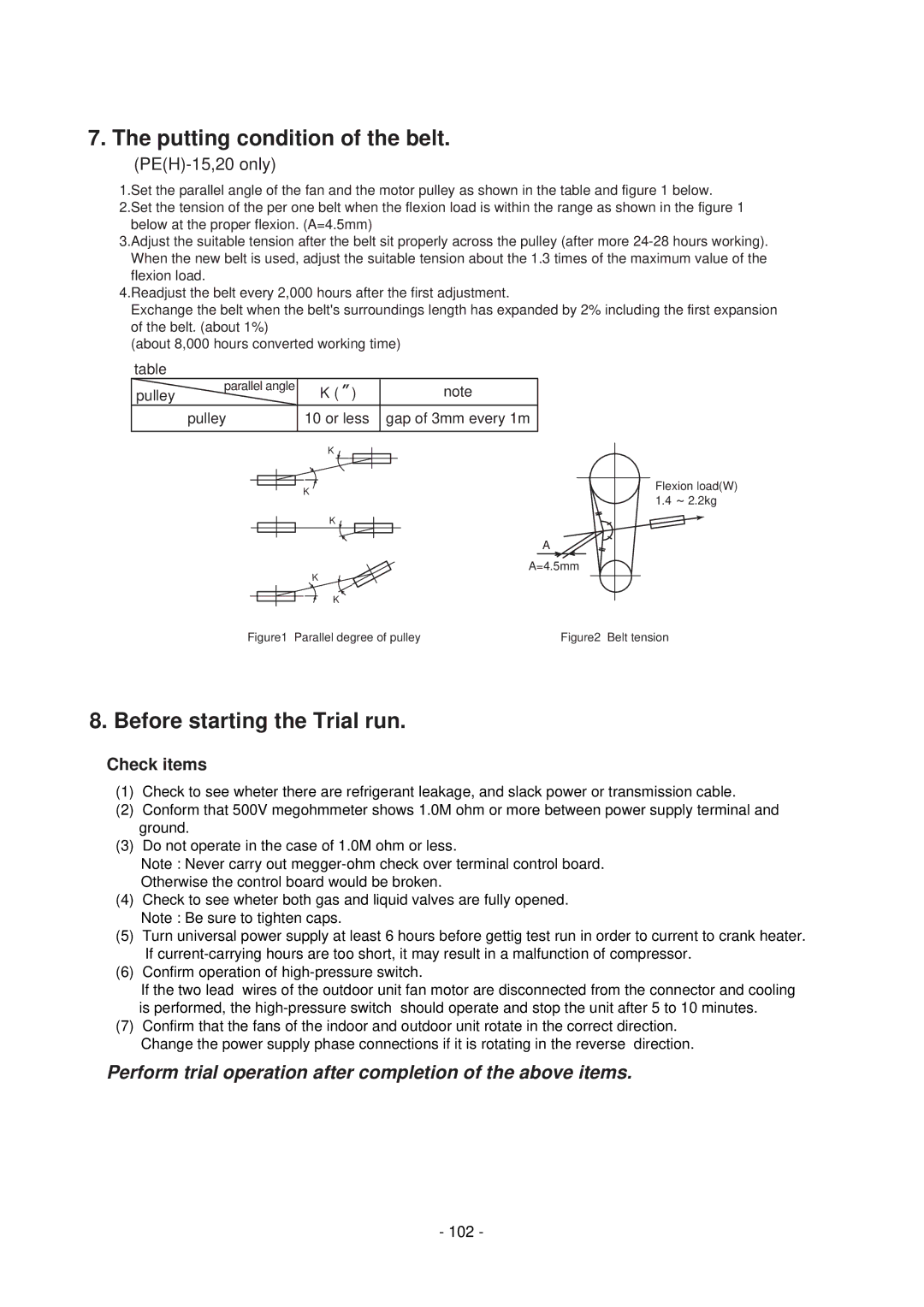

1.Set the parallel angle of the fan and the motor pulley as shown in the table and figure 1 below. 2.Set the tension of the per one belt when the flexion load is within the range as shown in the figure 1

below at the proper flexion. (A=4.5mm)

3.Adjust the suitable tension after the belt sit properly across the pulley (after more

4.Readjust the belt every 2,000 hours after the first adjustment.

Exchange the belt when the belt's surroundings length has expanded by 2% including the first expansion of the belt. (about 1%)

(about 8,000 hours converted working time)

table

parallel angle | K ( ) | note |

pulley | ||

pulley | 10 or less | gap of 3mm every 1m |

|

|

|

K

K

K

A

A=4.5mm

Flexion load(W) 1.4  2.2kg

2.2kg

K

Figure1 Parallel degree of pulley | Figure2 Belt tension |

8. Before starting the Trial run.

Check items

(1)Check to see wheter there are refrigerant leakage, and slack power or transmission cable.

(2)Conform that 500V megohmmeter shows 1.0M ohm or more between power supply terminal and ground.

(3)Do not operate in the case of 1.0M ohm or less.

Note : Never carry out

(4)Check to see wheter both gas and liquid valves are fully opened. Note : Be sure to tighten caps.

(5)Turn universal power supply at least 6 hours before gettig test run in order to current to crank heater. If

(6)Confirm operation of

If the two lead wires of the outdoor unit fan motor are disconnected from the connector and cooling is performed, the

(7)Confirm that the fans of the indoor and outdoor unit rotate in the correct direction. Change the power supply phase connections if it is rotating in the reverse direction.

Perform trial operation after completion of the above items.

- 102 -