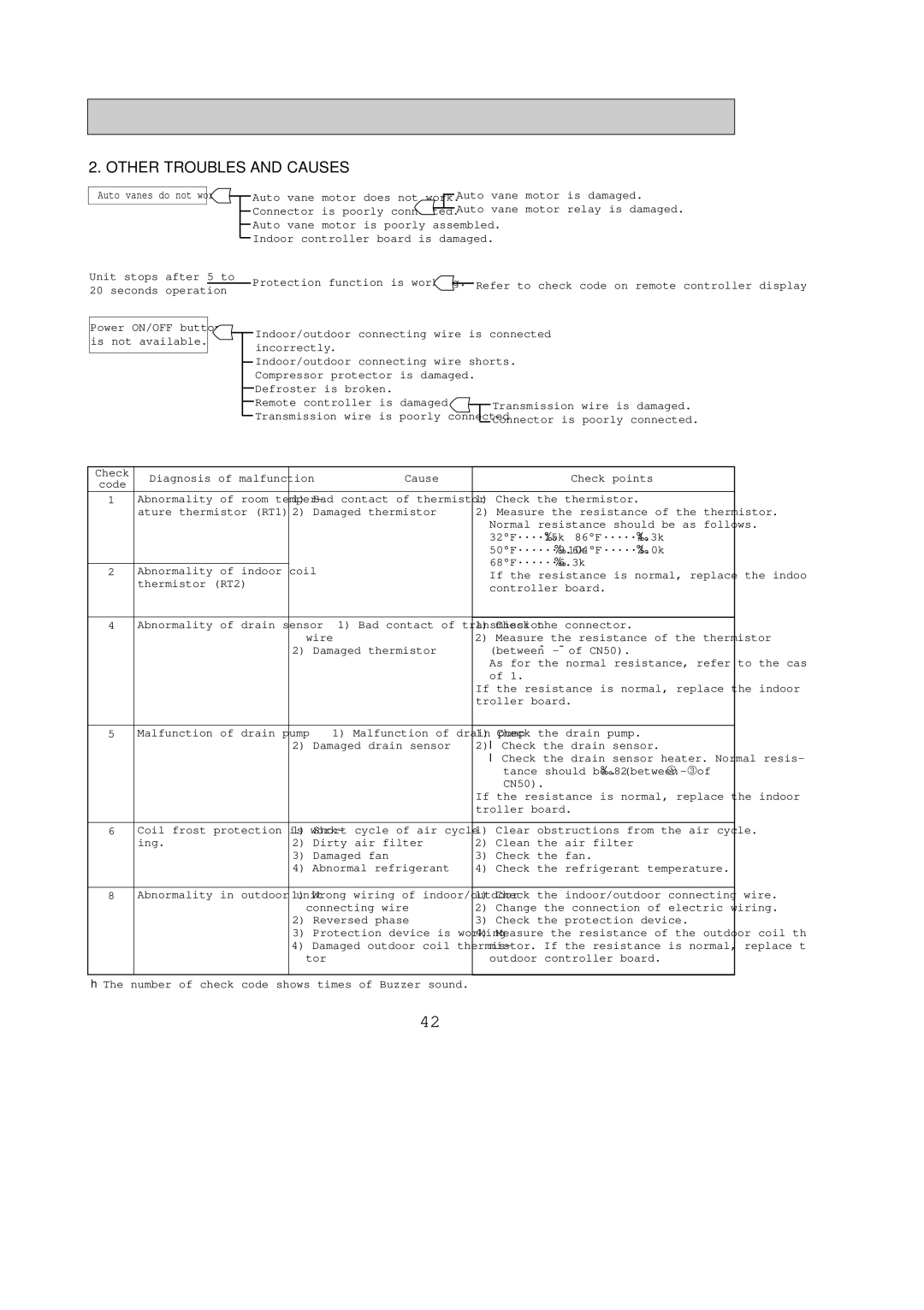

2. OTHER TROUBLES AND CAUSES

Auto vanes do not work. |

|

|

|

| Auto vane motor does not work. |

| |

|

|

|

|

| |||

|

|

|

|

| Connector is poorly connected. |

|

|

|

|

|

|

|

|

| |

|

|

|

| ||||

|

|

|

|

| Auto vane motor is poorly assembled. | ||

|

|

|

| ||||

|

|

|

|

| Indoor controller board is damaged. | ||

|

|

|

| ||||

Auto vane motor is damaged. Auto vane motor relay is damaged.

Unit stops after 5 to | Protection function is working. | Refer to check code on remote controller display. | |

20 seconds operation | |||

|

|

Power ON/OFF button is not available.

![]() Indoor/outdoor connecting wire is connected incorrectly.

Indoor/outdoor connecting wire is connected incorrectly.

Indoor/outdoor connecting wire shorts. Compressor protector is damaged. Defroster is broken.

Remote controller is damaged. Transmission wire is poorly connected

Transmission wire is damaged. Connector is poorly connected.

Check | Diagnosis of malfunction |

| Cause |

|

| Check points |

code |

|

|

| |||

|

|

|

|

|

| |

1 | Abnormality of room temper- | 1) | Bad contact of thermistor | 1) | Check the thermistor. | |

| ature thermistor (RT1) | 2) | Damaged thermistor | 2) Measure the resistance of the thermistor. | ||

|

|

|

|

| Normal resistance should be as follows. | |

|

|

|

|

| 32°F····15kΩ | 86°F·····4.3kΩ |

|

|

|

|

| 50°F······9.6kΩ 104°F·····3.0kΩ | |

|

|

|

|

| 68°F······6.3kΩ |

|

2 | Abnormality of indoor coil |

|

|

|

| |

|

|

| If the resistance is normal, replace the indoor | |||

| thermistor (RT2) |

|

|

| controller board. | |

|

|

|

|

| ||

|

|

|

|

| ||

4 | Abnormality of drain sensor | 1) Bad contact of transmission | 1) | Check the connector. | ||

|

|

| wire | 2) | Measure the resistance of the thermistor | |

|

| 2) | Damaged thermistor |

| (between ➃ - ➄of CN50). | |

|

|

|

|

| As for the normal resistance, refer to the case | |

|

|

|

|

| of 1. |

|

|

|

|

| If the resistance is normal, replace the indoor con- | ||

|

|

|

| troller board. |

| |

|

|

|

|

| ||

5 | Malfunction of drain pump | 1) | Malfunction of drain pump | 1) Check the drain pump. | ||

|

| 2) | Damaged drain sensor | 2) ● Check the drain sensor. | ||

|

|

|

|

| ● Check the drain sensor heater. Normal resis- | |

|

|

|

|

| tance should be 82Ω . (between 1 - 3of | |

|

|

|

|

| CN50). |

|

|

|

|

| If the resistance is normal, replace the indoor con- | ||

|

|

|

| troller board. |

| |

|

|

|

|

|

| |

6 | Coil frost protection is work- | 1) | Short cycle of air cycle | 1) | Clear obstructions from the air cycle. | |

| ing. | 2) | Dirty air filter | 2) | Clean the air filter | |

|

| 3) | Damaged fan | 3) | Check the fan. |

|

|

| 4) Abnormal refrigerant | 4) | Check the refrigerant temperature. | ||

|

|

|

|

| ||

8 | Abnormality in outdoor unit | 1) Wrong wiring of indoor/outdoor | 1) | Check the indoor/outdoor connecting wire. | ||

|

|

| connecting wire | 2) | Change the connection of electric wiring. | |

|

| 2) | Reversed phase | 3) | Check the protection device. | |

|

| 3) | Protection device is working | 4) | Measure the resistance of the outdoor coil ther- | |

|

| 4) Damaged outdoor coil thermis- |

| mistor. If the resistance is normal, replace the | ||

|

|

| tor |

| outdoor controller board. | |

|

|

|

|

|

|

|

❈The number of check code shows times of Buzzer sound.

42