10.When making duplex prints, misdetection of paper wrapping may occur because the paper delivery sensor detects the black area at the leading edge of the back side. Keep more than 10mm/O.4° blank area at the leading edge of the back side of the printing paper.

11.Do not use the thermal head cleaner for anything but cleaning the ther- mal head. Also, be Sure to read ttle cautions about the thermal head cleaner, and be careful as this cleaner is an alcohol.

Take note of the following regarding the cleaner:

●Do not take internally.

●Do not breathe it.

●Keep out of the reach of children.

●If it comes in contact with skin, wash well with water.

●Keep away from eyes. If it comes in contact with your eyes, wash well. If irritation occurs, contact your doctor.

●Never place it whet’e it will be exposed to heat.

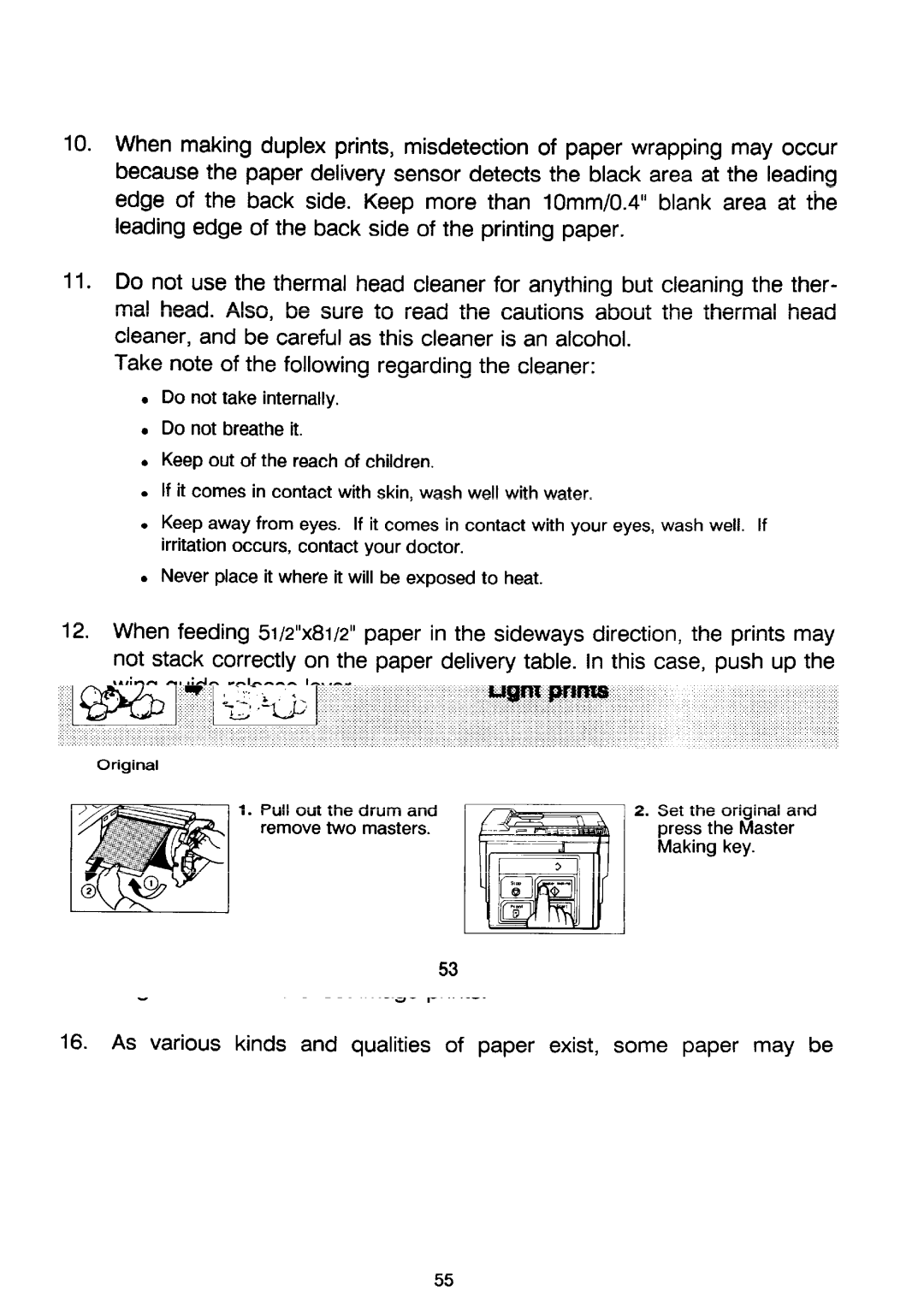

12.When feeding 51/2’’x8l/2° paper in the sideways direction, the prints may

not stack correctly on the paper delivery table. In this case, push up the wing guide release lever.

13.Perform a test print using the Proof key as the first few prints may be light.

14.When the machine is m and the power source is less than 90% of the specified amount, printing quality will decrease. Therefore, make sure the mains supply is at least 90% of the required amount.

15.Such paper as postcards do not absorb ink well. Therefore, offset im- ages may appear on the rear side of following prints. Solid image originals will make offset image prints.

16.AS various kinds and qualities of paper exist, Some paper may be wrapped around the drum and/or cause jams.

55