Unit 3: Installation

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration before printer purchase. Ideally, the media width will be equal to, or just narrower than, the print head. Using media that does not cover the print head will allow the platen roller to tread on it and wear it out. The media edge will also wear a groove in the platen roller affecting print quality.

MEDIA & RIBBON LOADING

There are two general media types that may be loaded and used; rolled and

Thermal transfer media requires the use of ribbon stock for print application. In such a scenario, it is the ribbon stock (carbon paper) that contains the ink that will be transfered to the media.

Direct thermal media has the ink embedded within and is brought to the surface through heat penetration by print head contact.

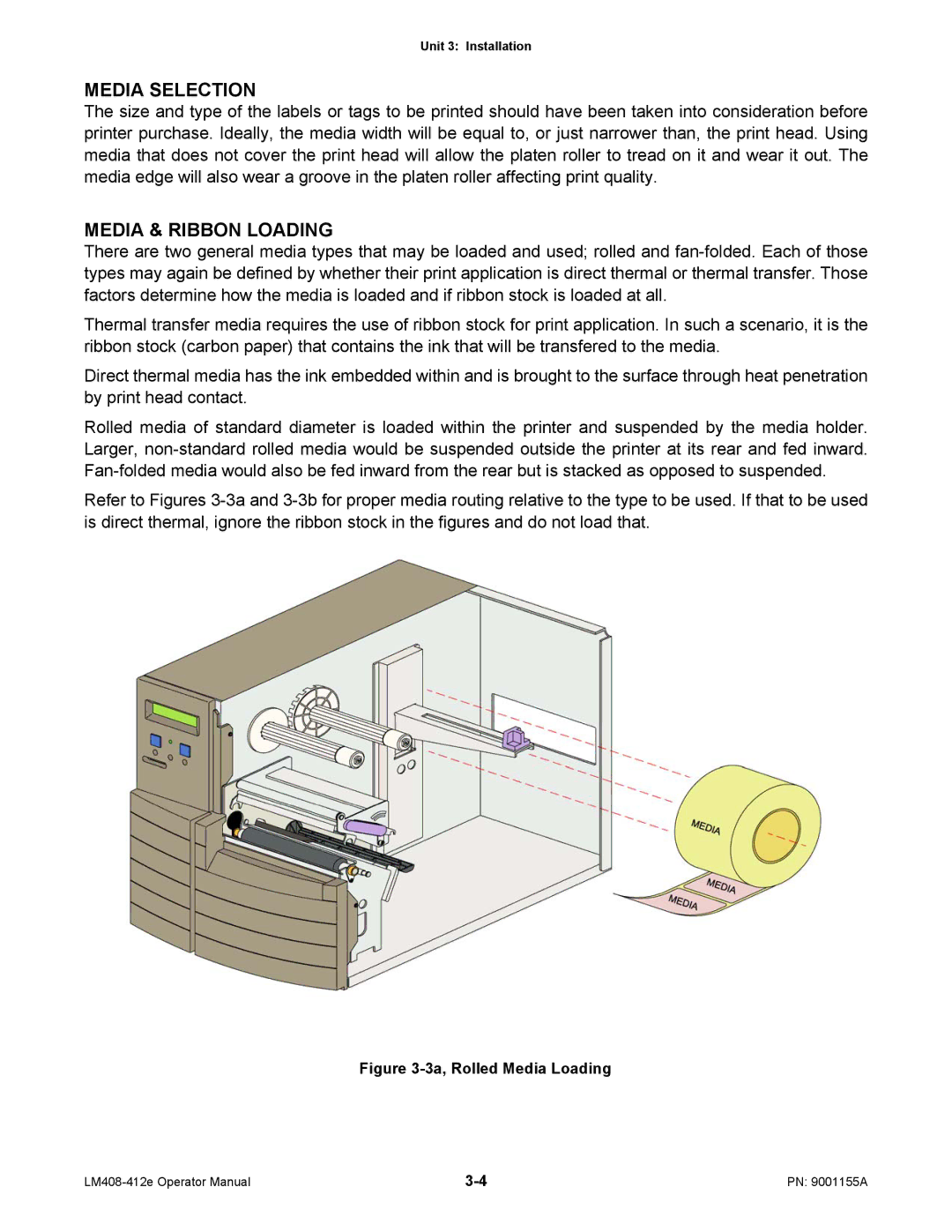

Rolled media of standard diameter is loaded within the printer and suspended by the media holder. Larger,

Refer to Figures

Figure 3-3a, Rolled Media Loading

PN: 9001155A |