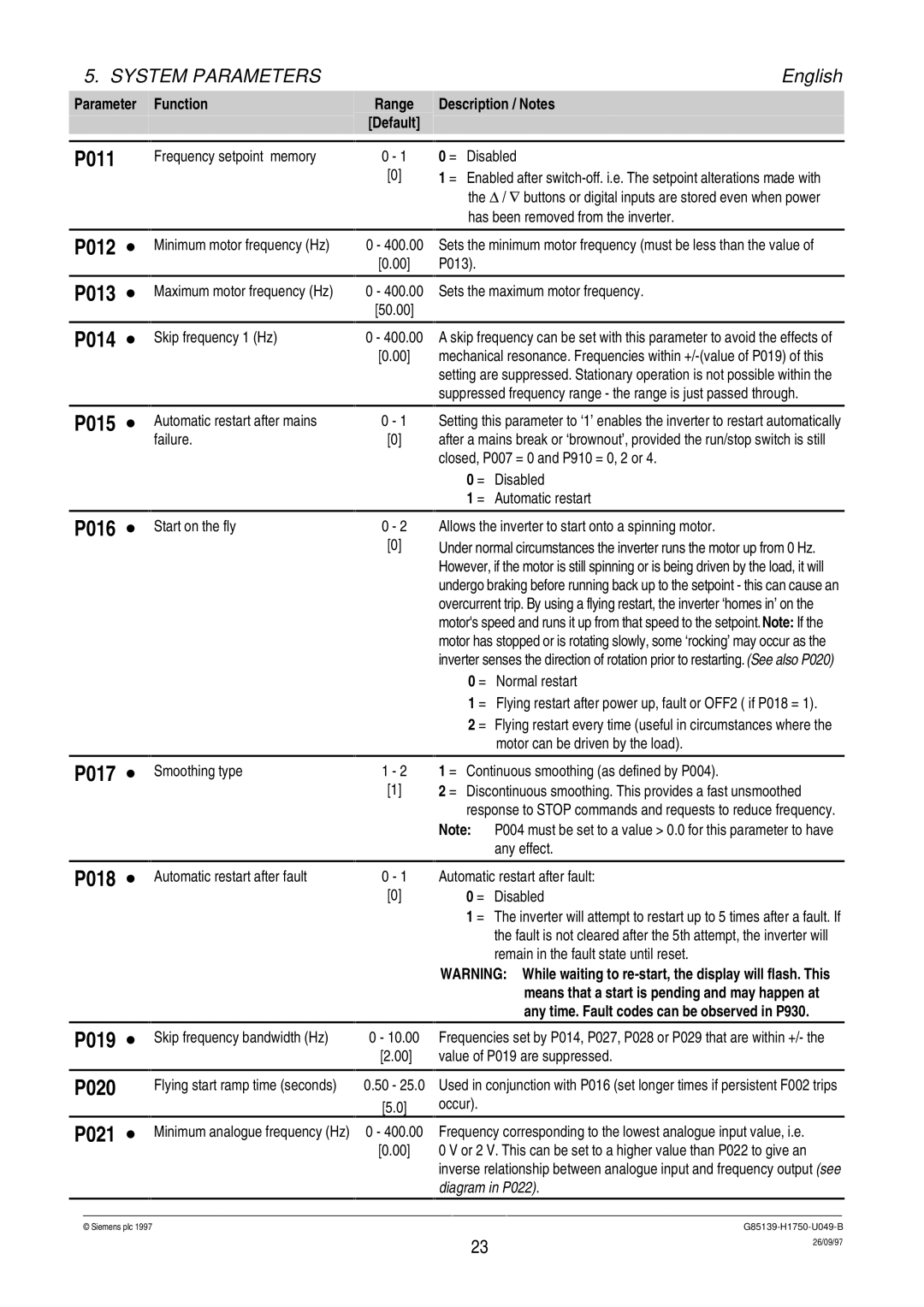

5. SYSTEM PARAMETERS | English |

Parameter

P011

| Function |

| Range |

|

|

| [Default] |

|

| ||

|

|

|

|

| Frequency setpoint memory | 0 - 1 | |

|

| [0] | |

Description / Notes

0 = Disabled

1 = Enabled after

P012 ∙

P013 ∙

P014 ∙

P015 ∙

Minimum motor frequency (Hz) | 0 - 400.00 |

| Sets the minimum motor frequency (must be less than the value of | ||

| [0.00] |

| P013). |

| |

|

|

|

|

| |

Maximum motor frequency (Hz) | 0 - 400.00 |

| Sets the maximum motor frequency. | ||

| [50.00] |

|

|

| |

|

|

|

|

| |

Skip frequency 1 (Hz) | 0 - 400.00 |

| A skip frequency can be set with this parameter to avoid the effects of | ||

| [0.00] |

| mechanical resonance. Frequencies within | ||

|

|

|

| setting are suppressed. Stationary operation is not possible within the | |

|

|

|

| suppressed frequency range - the range is just passed through. | |

|

|

|

|

| |

Automatic restart after mains | 0 - 1 |

| Setting this parameter to ‘1’ enables the inverter to restart automatically | ||

failure. | [0] |

| after a mains break or ‘brownout’, provided the run/stop switch is still | ||

|

|

|

| closed, P007 = 0 and P910 = 0, 2 or 4. | |

|

|

| 0 = | Disabled | |

|

|

| 1 = | Automatic restart | |

P016 ∙

Start on the fly | 0 - 2 |

| [0] |

Allows the inverter to start onto a spinning motor.

Under normal circumstances the inverter runs the motor up from 0 Hz. However, if the motor is still spinning or is being driven by the load, it will undergo braking before running back up to the setpoint - this can cause an overcurrent trip. By using a flying restart, the inverter ‘homes in’ on the motor's speed and runs it up from that speed to the setpoint.Note: If the motor has stopped or is rotating slowly, some ‘rocking’ may occur as the inverter senses the direction of rotation prior to restarting.(See also P020)

0 = Normal restart

1 = Flying restart after power up, fault or OFF2 ( if P018 = 1).

2 = Flying restart every time (useful in circumstances where the motor can be driven by the load).

P017 ∙

P018 ∙

Smoothing type | 1 - 2 | 1 = | Continuous smoothing (as defined by P004). |

| [1] | 2 = | Discontinuous smoothing. This provides a fast unsmoothed |

|

|

| response to STOP commands and requests to reduce frequency. |

Note: P004 must be set to a value > 0.0 for this parameter to have any effect.

Automatic restart after fault | 0 - 1 | Automatic restart after fault: | |

| [0] | 0 = | Disabled |

|

| 1 = | The inverter will attempt to restart up to 5 times after a fault. If |

|

|

| the fault is not cleared after the 5th attempt, the inverter will |

|

|

| remain in the fault state until reset. |

WARNING: While waiting to

P019 ∙

P020

P021 ∙

Skip frequency bandwidth (Hz) | 0 - 10.00 |

| Frequencies set by P014, P027, P028 or P029 that are within +/- the | |

| [2.00] |

| value of P019 are suppressed. | |

|

|

|

|

|

Flying start ramp time (seconds) | 0.50 - 25.0 |

| Used in conjunction with P016 (set longer times if persistent F002 trips | |

|

| [5.0] |

| occur). |

Minimum analogue frequency (Hz) | 0 - 400.00 |

| Frequency corresponding to the lowest analogue input value, i.e. | |

| [0.00] |

| 0 V or 2 V. This can be set to a higher value than P022 to give an | |

|

|

|

| inverse relationship between analogue input and frequency output (see |

|

|

|

| diagram in P022). |

© Siemens plc 1997G85139-H1750-U049-B

23 | 26/09/97 |

|