P R E P A R A T I O N | For Machines Mfg. Since 3/11 |

Test Run

After all preparation steps have been completed, the machine and its safety features must be tested to ensure correct operation. If you discover a problem with the operation of the machine or its safety components, shut the machine down, disconnect it from power, and do not operate it further until you have resolved the problem.

A Troubleshooting section is provided, starting on Page 88, to assist you with solutions if a problem occurs or if the lathe does not function as described in this section.

If you need additional help after reviewing the troubleshooting section, or you are not confident troubleshooting the machine on your own, contact our Tech Support at (360)

To test run your machine:

1.Make sure the master power switch

(Figure 24) on the rear of the machine is turned OFF.

Master Power

Switch

Figure 24. Location of the master power switch.

2.Read and follow the safety instructions at the beginning of the manual, take all required safety precautions, and make sure all previous preparation steps discussed in this manual have been followed and completed.

3.Clear away all tools and objects used during assembly, lubrication, and preparation.

4.Make sure that the chuck and jaws, if installed, are secure (refer to Chuck and Faceplate Mounting on Page 37).

Note: If a chuck is not installed on the lathe, you do not need to install one for this test.

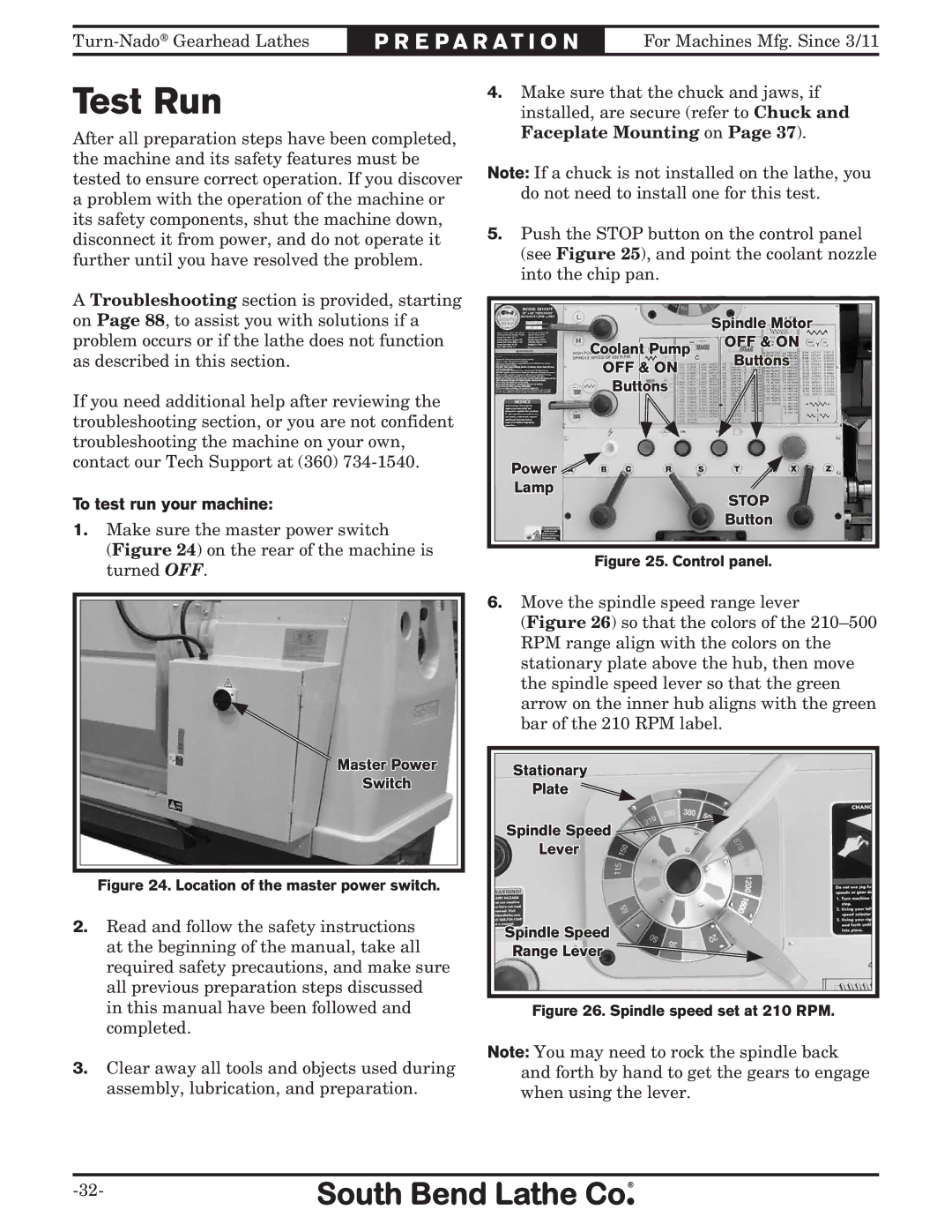

5.Push the STOP button on the control panel (see Figure 25), and point the coolant nozzle into the chip pan.

| Spindle Motor | |

Coolant Pump | OFF & ON | |

Buttons | ||

OFF & ON | ||

| ||

Buttons |

|

Power ![]()

Lamp

STOP

Button

Figure 25. Control panel.

6.Move the spindle speed range lever

(Figure 26) so that the colors of the 210–500 RPM range align with the colors on the stationary plate above the hub, then move the spindle speed lever so that the green arrow on the inner hub aligns with the green bar of the 210 RPM label.

Stationary

Plate

Spindle Speed ![]()

Lever

Spindle Speed

Range Lever

Figure 26. Spindle speed set at 210 RPM.

Note: You may need to rock the spindle back and forth by hand to get the gears to engage when using the lever.