P R E P A R A T I O N | For Machines Mfg. Since 3/11 |

Lubricating Lathe

GEARBOXES MUST

BE FILLED WITH OIL!

LATHE MAY NOT

HAVE OIL INCLUDED!

Refer to the Lubrication Section in this Manual for Recommended Oil Type.

The headstock,

Damage caused to the bearings and gears from running the lathe without oil in the reservoirs will not be covered under warranty. Refer to the Lubrication section, beginning on Page 68, for details on how to check, add oil, and prime the headstock oil pump.

In addition to the reservoirs, we also recommend that you lubricate all other points on the machine at this time. This can be accomplished by following the maintenance schedule on Page 66.

Note: If this lathe was shipped with oil in the reservoirs, do not change that oil until after the test run and spindle

Adding Coolant

Add the coolant of your choice now. For detailed instructions on where the coolant tank is located and how to add fluid, refer to Coolant System Service on Page 74.

Power Connection

After you have completed all previous setup instructions and circuit requirements, the machine is ready to be connected to the power supply.

Due to the complexity required for planning, bending, and installing the conduit necessary for a

Hardwire setups typically require power supply wires to be enclosed inside of a solid or flexible conduit, which is securely mounted at both ends with the appropriate conduit fittings. All work must adhere to the required electrical codes.

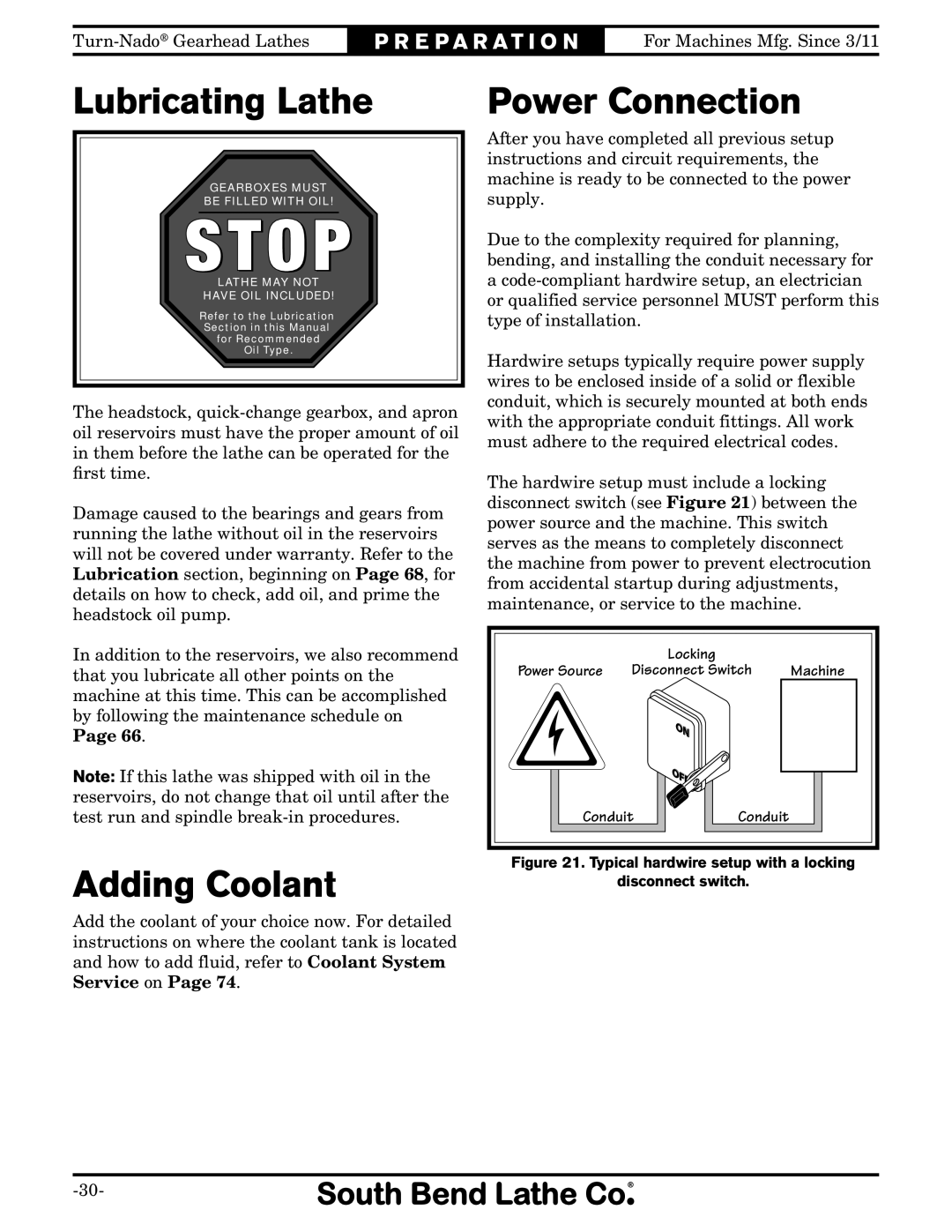

The hardwire setup must include a locking disconnect switch (see Figure 21) between the power source and the machine. This switch serves as the means to completely disconnect the machine from power to prevent electrocution from accidental startup during adjustments, maintenance, or service to the machine.

|

| Locking |

|

Power Source | Disconnect Switch | Machine | |

Conduit | Conduit |

| |