M A I N T E N A N C E | For Machines Mfg. Since 3/11 |

Longitudinal Leadscrew

Oil Type....... Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount | As Needed |

Lubrication Frequency | Daily |

Before lubricating the leadscrew, clean it first with mineral spirits. A stiff brush works well to help clean out the threads. Make sure to move the carriage out of the way, so you can clean the entire length of the leadscrew.

Apply a thin coat of oil along the length of the leadscrew. Use a stiff brush to make sure the oil is applied evenly and down into the threads.

Note: In some environments, abrasive material can become caught in the leadscrew lubricant and drawn into the half nut. In this case, lubricate the leadscrew with a quality dry lubricant.

Ball Oilers

Oil Type | Mobil Vactra 2 or ISO 68 Equivalent | ||

Oil Amount | As required | ||

Pump Oil Can w/Plastic or Rubber Cone Tip | 1 | ||

Lubrication Frequency | Before and After Use | ||

Proper lubrication of ball oilers is done with a

Lubricate the ball oilers before and after machine use, and more frequently under heavy use. When lubricating ball oilers, first clean the outside surface to remove any dust or grime. Push the rubber or plastic tip of the oil can nozzle against the ball oiler to create a hydraulic seal, then pump the oil can once or twice. If you see sludge and contaminants coming out of the lubrication area, keep pumping the oil can until the oil runs clear. When finished, wipe away any excess oil.

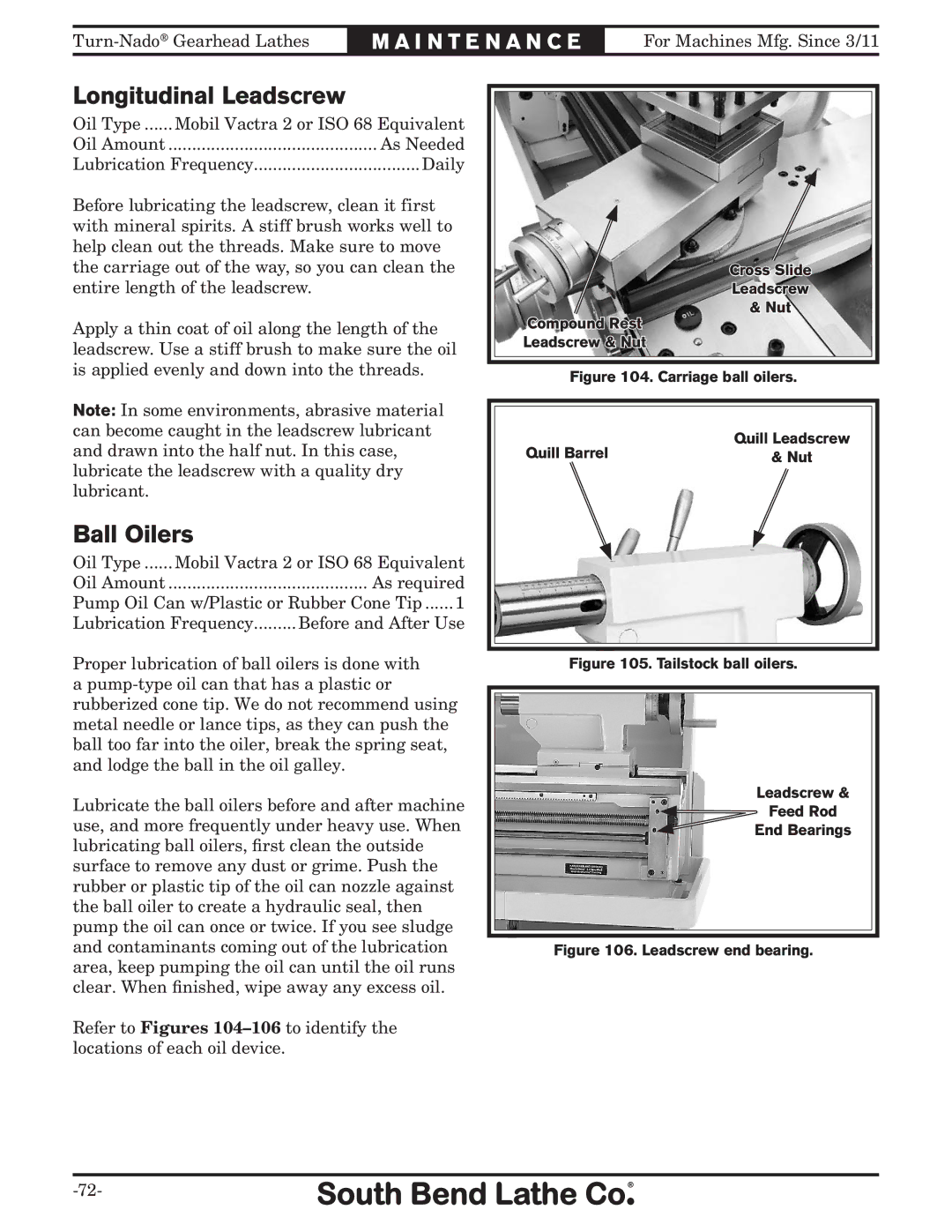

Refer to Figures

Cross Slide

Leadscrew

& Nut

Compound Rest

Leadscrew & Nut

Figure 104. Carriage ball oilers.

Quill Barrel | Quill Leadscrew |

& Nut |