M A I N T E N A N C E | For Machines Mfg. Since 3/11 |

Draining Oil

Place a catch pan under the

Apron

Oil Type | Mobil Vactra 2 or ISO 68 Equivalent | |

Oil Amount | 2.1 Quarts | |

Check/Add Frequency | ..................................... Daily | |

Change Frequency | Annually | |

Checking Oil Level

The apron has the proper amount of oil when the sight glass shown in Figure 101 is halfway full.

Important: Keep in mind that the apron one- shot oiler draws the oil from the apron reservoir. Check this oil level often when using the one- shot oiler.

Oiler

Fill![]()

![]() Plug

Plug

Sight

Glass

Figure 101. Location of apron oil sight glass.

Adding Oil

Remove the

Draining Oil & Flushing Reservoir

Since the apron oil reservoir supplies the one- shot oiler, the oil is constantly being refreshed when the reservoir is filled. However, small metal particles may accumulate at the bottom of the reservoir with normal use. Therefore, to keep the reservoir clean, drain and flush it at least once a year.

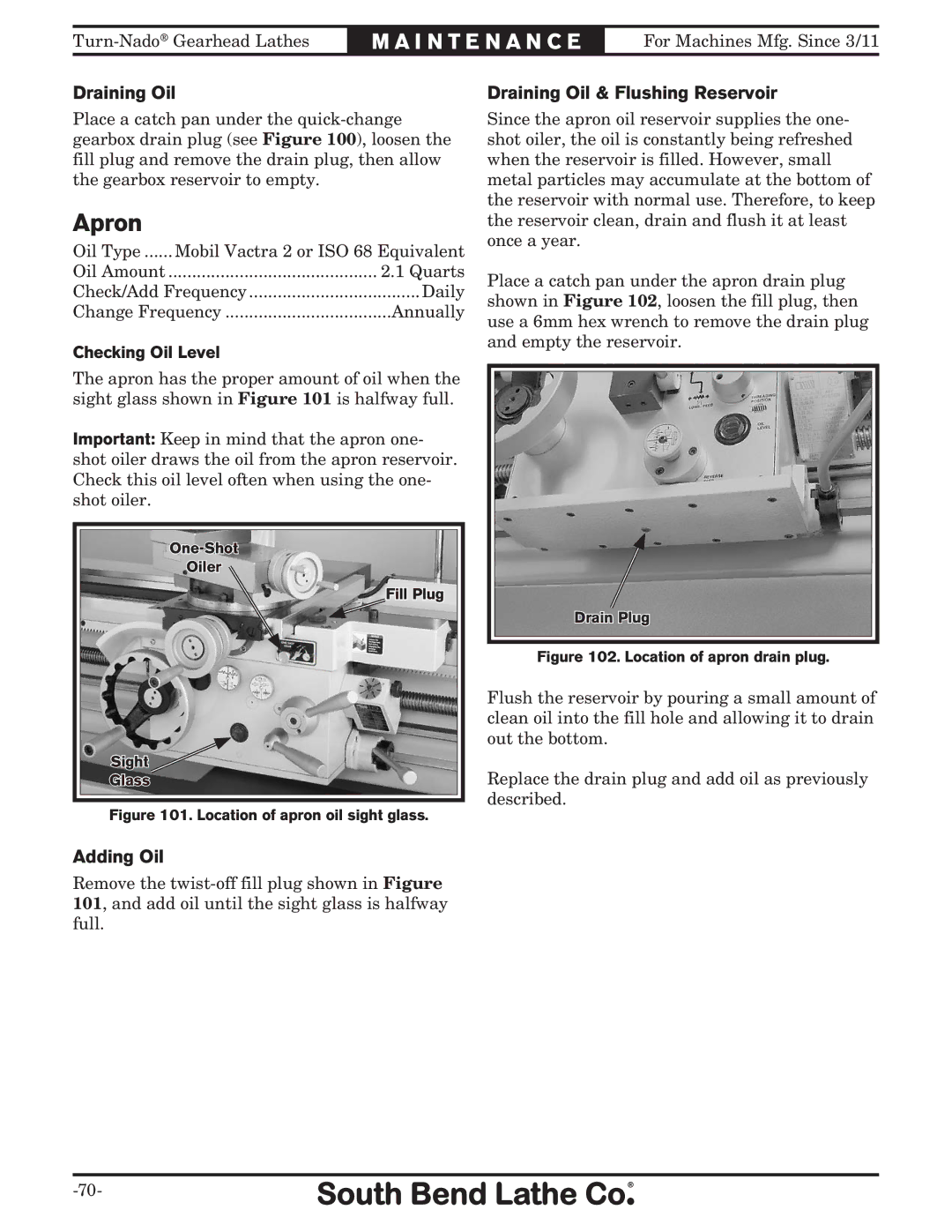

Place a catch pan under the apron drain plug shown in Figure 102, loosen the fill plug, then use a 6mm hex wrench to remove the drain plug and empty the reservoir.

Drain Plug

Figure 102. Location of apron drain plug.

Flush the reservoir by pouring a small amount of clean oil into the fill hole and allowing it to drain out the bottom.

Replace the drain plug and add oil as previously described.