O P E R A T I O N | For Machines Mfg. Since 3/11 |

End Gears

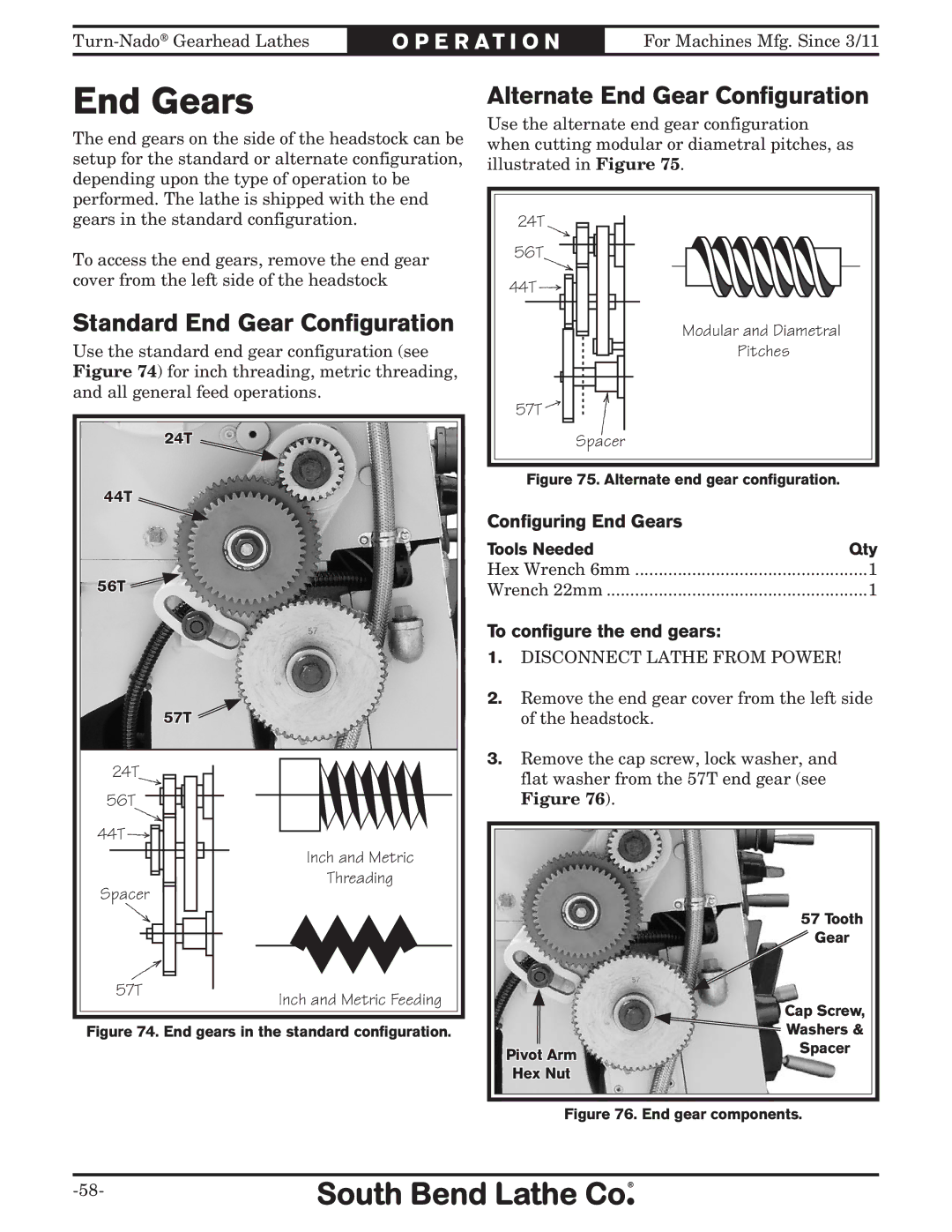

The end gears on the side of the headstock can be setup for the standard or alternate configuration, depending upon the type of operation to be performed. The lathe is shipped with the end gears in the standard configuration.

To access the end gears, remove the end gear cover from the left side of the headstock

Standard End Gear Configuration

Use the standard end gear configuration (see Figure 74) for inch threading, metric threading, and all general feed operations.

| 24T |

44T |

|

56T |

|

| 57T |

24T |

|

56T |

|

44T |

|

| Inch and Metric |

Spacer | Threading |

| |

57T | Inch and Metric Feeding |

|

Figure 74. End gears in the standard configuration.

Alternate End Gear Configuration

Use the alternate end gear configuration when cutting modular or diametral pitches, as illustrated in Figure 75.

24T |

56T |

44T |

Modular and Diametral |

Pitches |

57T |

Spacer |

Figure 75. Alternate end gear configuration.

Configuring End Gears |

|

Tools Needed | Qty |

Hex Wrench 6mm | 1 |

Wrench 22mm | 1 |

To configure the end gears:

1.DISCONNECT LATHE FROM POWER!

2.Remove the end gear cover from the left side of the headstock.

3.Remove the cap screw, lock washer, and flat washer from the 57T end gear (see Figure 76).

57 Tooth

Gear

Cap Screw,

![]() Washers &

Washers &

Pivot ArmSpacer

Hex Nut