O P E R A T I O N | For Machines Mfg. Since 3/11 |

Chuck Installation

To ensure accurate work, it is extremely important to make sure the spindle nose and chuck mating surfaces/tapers are clean. Even a small amount of lint or debris can affect accuracy.

The chuck is properly installed when all camlocks are tight, the spindle and chuck tapers firmly lock together, and the back of chuck is firmly seated against the face of the spindle all the way

To install the chuck:

1.DISCONNECT LATHE FROM POWER!

2.Use an appropriate lifting, support, or protective device to protect the ways and support the chuck during the installation process.

3.Clean and lightly oil the camlock studs, then thoroughly clean the mating surfaces of the spindle and chuck.

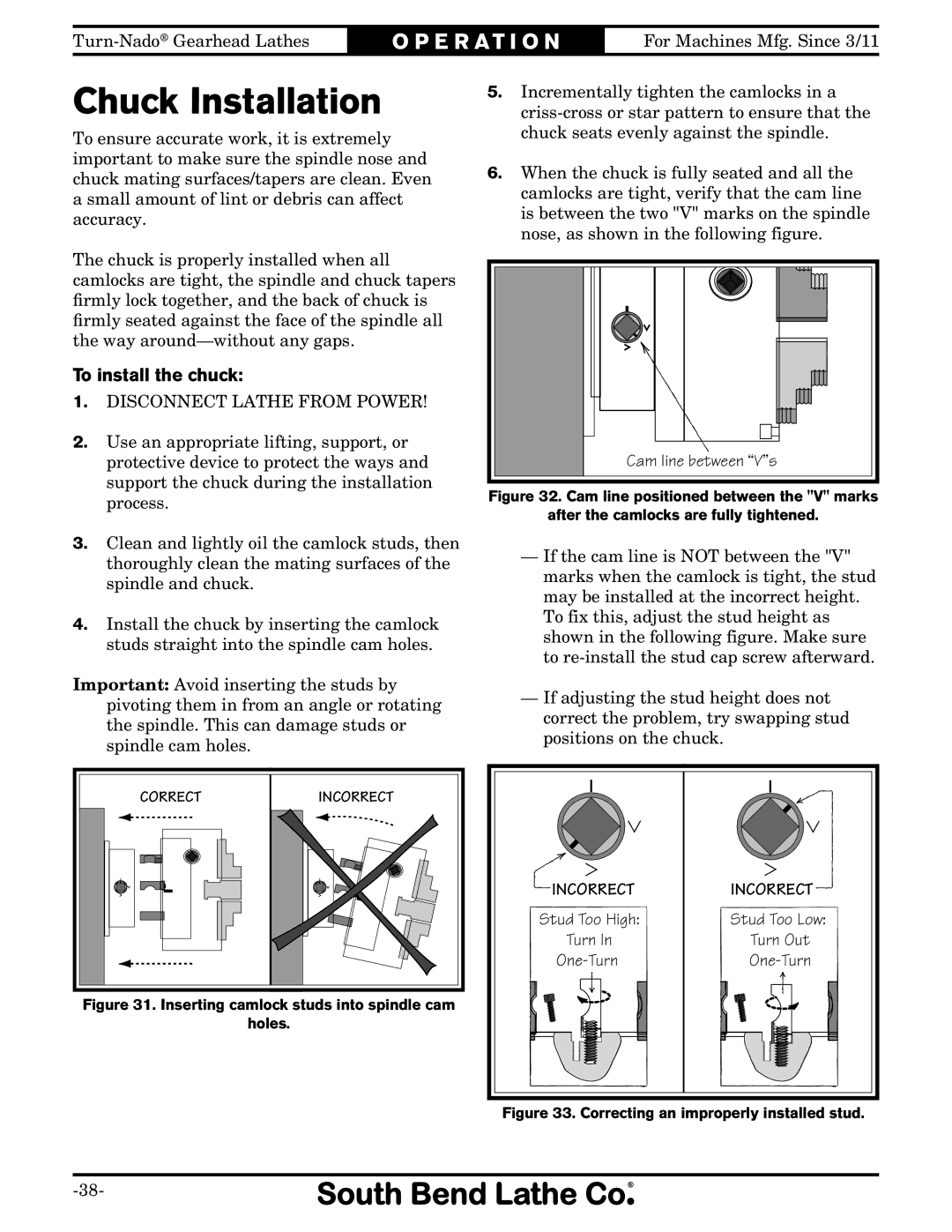

4.Install the chuck by inserting the camlock studs straight into the spindle cam holes.

Important: Avoid inserting the studs by pivoting them in from an angle or rotating the spindle. This can damage studs or spindle cam holes.

CORRECT | INCORRECT |

Figure 31. Inserting camlock studs into spindle cam

holes.

5.Incrementally tighten the camlocks in a

6.When the chuck is fully seated and all the camlocks are tight, verify that the cam line is between the two "V" marks on the spindle nose, as shown in the following figure.

Cam line between “V”s

Figure 32. Cam line positioned between the "V" marks

after the camlocks are fully tightened.

—If the cam line is NOT between the "V" marks when the camlock is tight, the stud may be installed at the incorrect height. To fix this, adjust the stud height as shown in the following figure. Make sure to

—If adjusting the stud height does not correct the problem, try swapping stud positions on the chuck.

INCORRECT | INCORRECT |

Stud Too High: | Stud Too Low: |

Turn In | Turn Out |