For Machines Mfg. Since 3/11 | O P E R A T I O N |

Chip Drawer

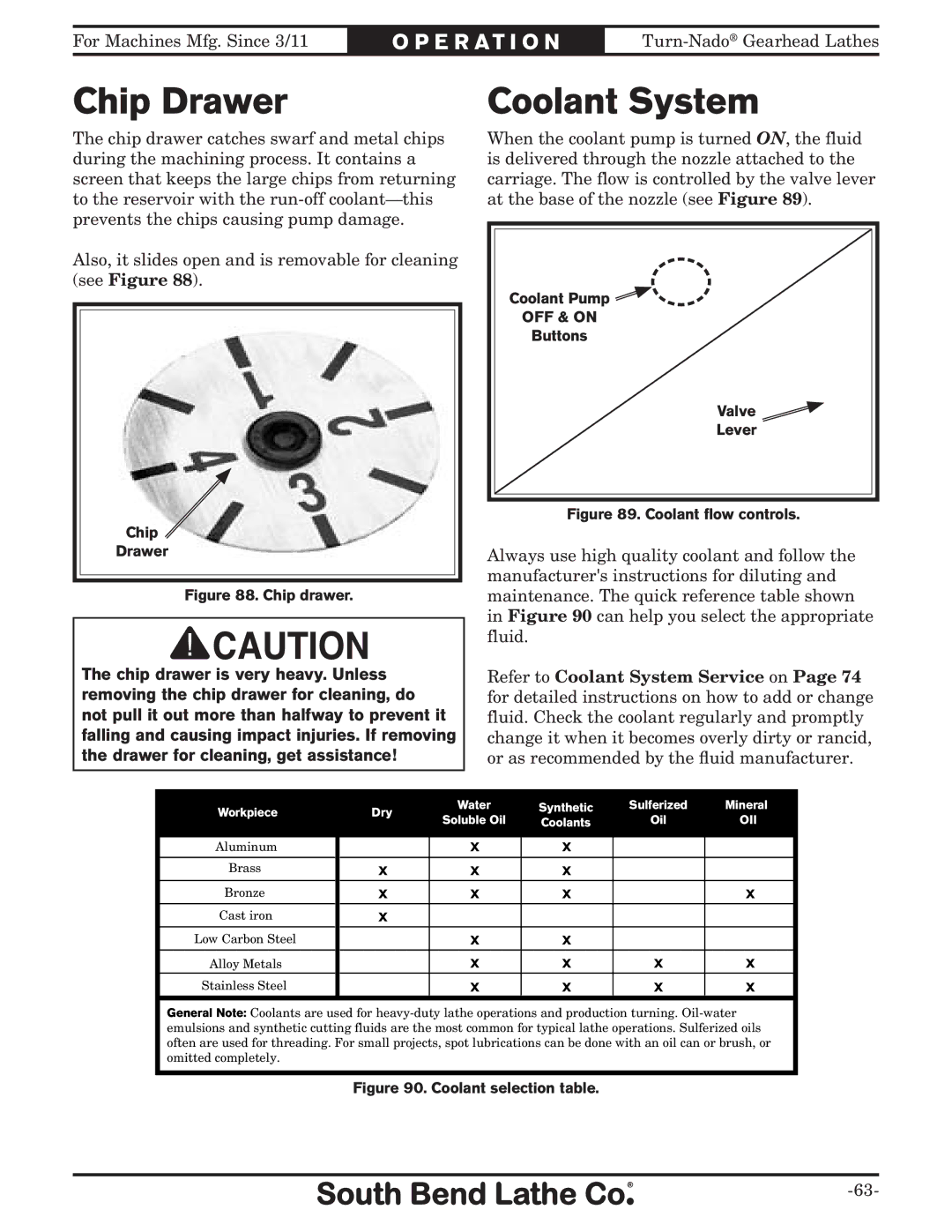

The chip drawer catches swarf and metal chips during the machining process. It contains a screen that keeps the large chips from returning to the reservoir with the

Also, it slides open and is removable for cleaning (see Figure 88).

Chip

Drawer

Figure 88. Chip drawer.

The chip drawer is very heavy. Unless removing the chip drawer for cleaning, do not pull it out more than halfway to prevent it falling and causing impact injuries. If removing the drawer for cleaning, get assistance!

Coolant System

When the coolant pump is turned ON, the fluid is delivered through the nozzle attached to the carriage. The flow is controlled by the valve lever at the base of the nozzle (see Figure 89).

Coolant Pump ![]()

![]()

OFF![]() & ON

& ON

Buttons

Valve ![]()

Lever

Figure 89. Coolant flow controls.

Always use high quality coolant and follow the manufacturer's instructions for diluting and maintenance. The quick reference table shown in Figure 90 can help you select the appropriate fluid.

Refer to Coolant System Service on Page 74 for detailed instructions on how to add or change fluid. Check the coolant regularly and promptly change it when it becomes overly dirty or rancid, or as recommended by the fluid manufacturer.

| Workpiece | Dry | Water | Synthetic | Sulferized | Mineral |

|

| Soluble Oil | Coolants | Oil | OIl |

| ||

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Aluminum |

| X | X |

|

|

|

|

|

|

|

|

|

|

|

| Brass | X | X | X |

|

|

|

| Bronze | X | X | X |

| X | |

| Cast iron | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Low Carbon Steel |

| X | X |

|

|

|

|

|

|

|

|

|

|

|

| Alloy Metals |

| X | X | X | X | |

|

|

|

|

|

|

|

|

| Stainless Steel |

| X | X | X | X | |

|

|

|

|

|

|

|

|

General Note: Coolants are used for