O P E R A T I O N | For Machines Mfg. Since 3/11 |

BIOLOGICAL & POISON

HAZARD!

Use the correct personal protection equipment when handling coolant. Follow federal, state, and fluid manufacturer requirements for proper disposal.

Running the pump without adequate fluid in the coolant tank may permanently damage it, which will not be covered under warranty.

To use the coolant system on your lathe:

1.Make sure the coolant tank is properly serviced and filled with the appropriate fluid, and that you are wearing the necessary personal protection equipment.

2.Position the coolant nozzle for your operation.

3.Use the coolant pump switch on the control panel to turn the pump ON.

4.Adjust the flow of coolant by using the valve lever near the base of the nozzle hose.

Important: Promptly clean any splashed fluid from the floor to avoid a slipping hazard.

Rod Support

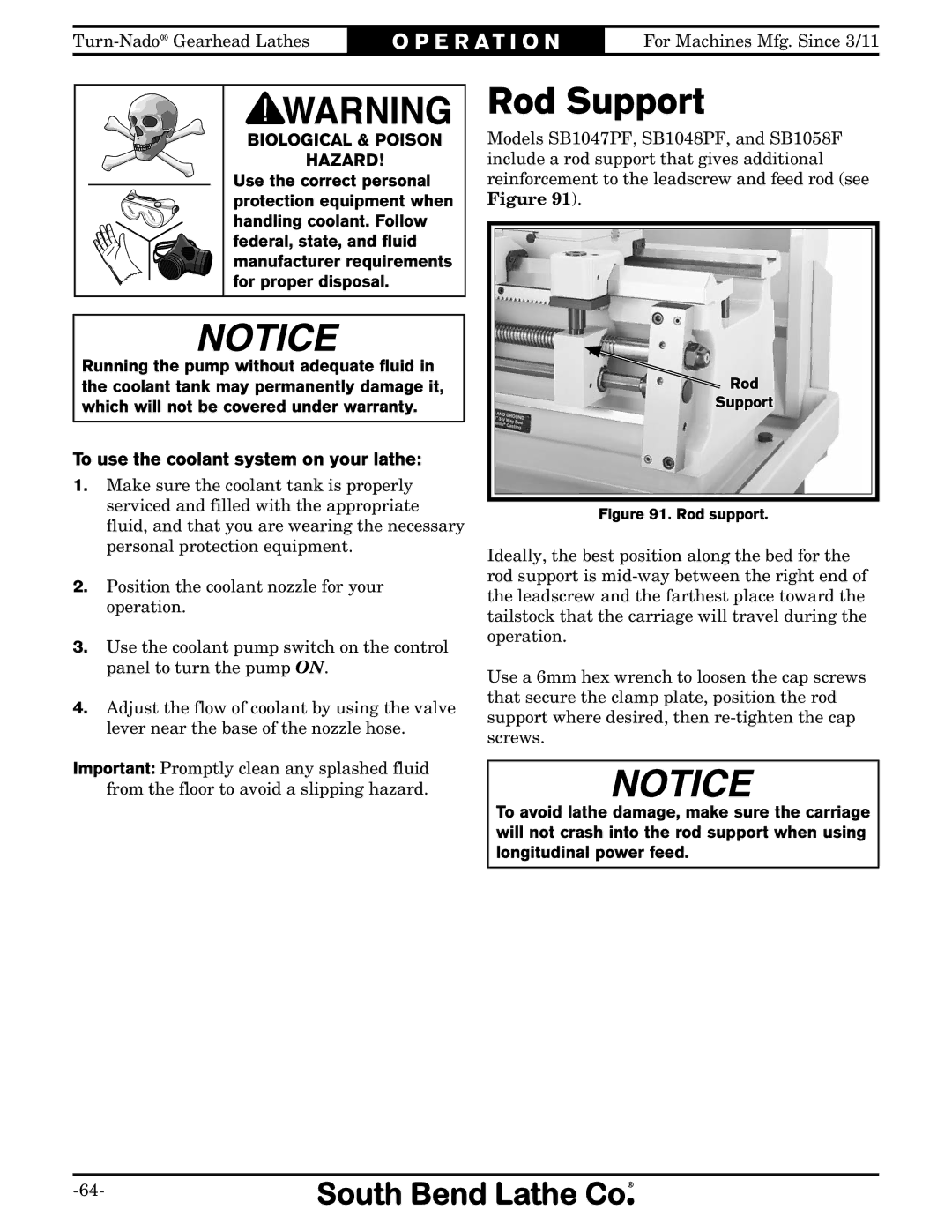

Models SB1047PF, SB1048PF, and SB1058F include a rod support that gives additional reinforcement to the leadscrew and feed rod (see Figure 91).

Rod

Support

Figure 91. Rod support.

Ideally, the best position along the bed for the rod support is

Use a 6mm hex wrench to loosen the cap screws that secure the clamp plate, position the rod support where desired, then

To avoid lathe damage, make sure the carriage will not crash into the rod support when using longitudinal power feed.