For Machines Mfg. Since 3/11 | P R E P A R A T I O N |

7.Move the gearbox range lever on the headstock to the neutral (middle) position to disable power feed, as shown in Figure 27.

LOW |

Neutral |

HIGH |

Figure 27. Gearbox range lever in neutral.

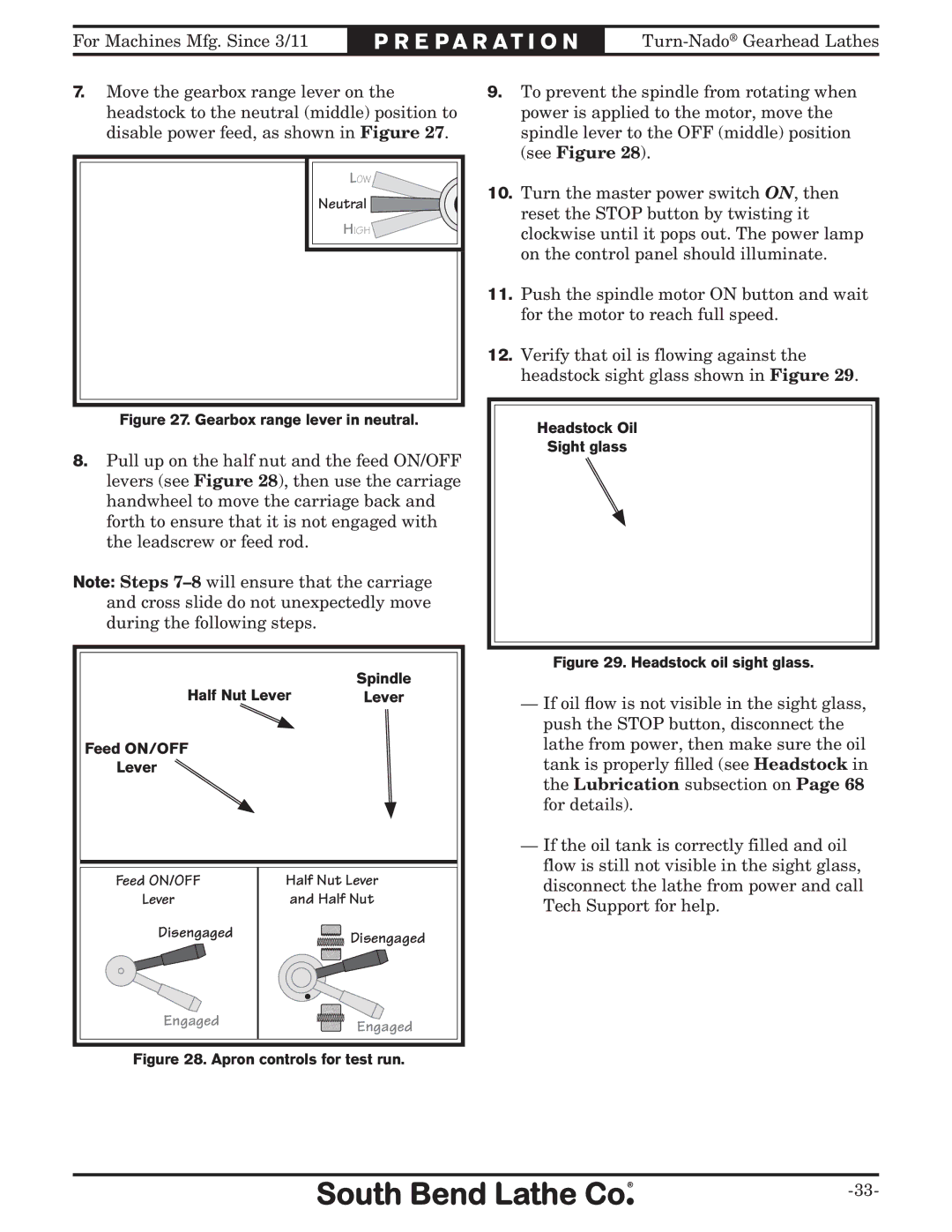

8.Pull up on the half nut and the feed ON/OFF levers (see Figure 28), then use the carriage handwheel to move the carriage back and forth to ensure that it is not engaged with the leadscrew or feed rod.

Note: Steps

9.To prevent the spindle from rotating when power is applied to the motor, move the spindle lever to the OFF (middle) position (see Figure 28).

10.Turn the master power switch ON, then reset the STOP button by twisting it clockwise until it pops out. The power lamp on the control panel should illuminate.

11.Push the spindle motor ON button and wait for the motor to reach full speed.

12.Verify that oil is flowing against the headstock sight glass shown in Figure 29.

Headstock Oil

Sight glass

Half Nut Lever | Spindle | |

Lever | ||

Feed ON/OFF |

|

|

Lever |

|

|

Feed ON/OFF | Half Nut Lever | |

Lever | and Half Nut | |

Disengaged |

| Disengaged |

|

| |

Engaged |

| Engaged |

|

| |

Figure 28. Apron controls for test run.

Figure 29. Headstock oil sight glass.

—If oil flow is not visible in the sight glass, push the STOP button, disconnect the lathe from power, then make sure the oil tank is properly filled (see Headstock in the Lubrication subsection on Page 68 for details).

—If the oil tank is correctly filled and oil flow is still not visible in the sight glass, disconnect the lathe from power and call Tech Support for help.