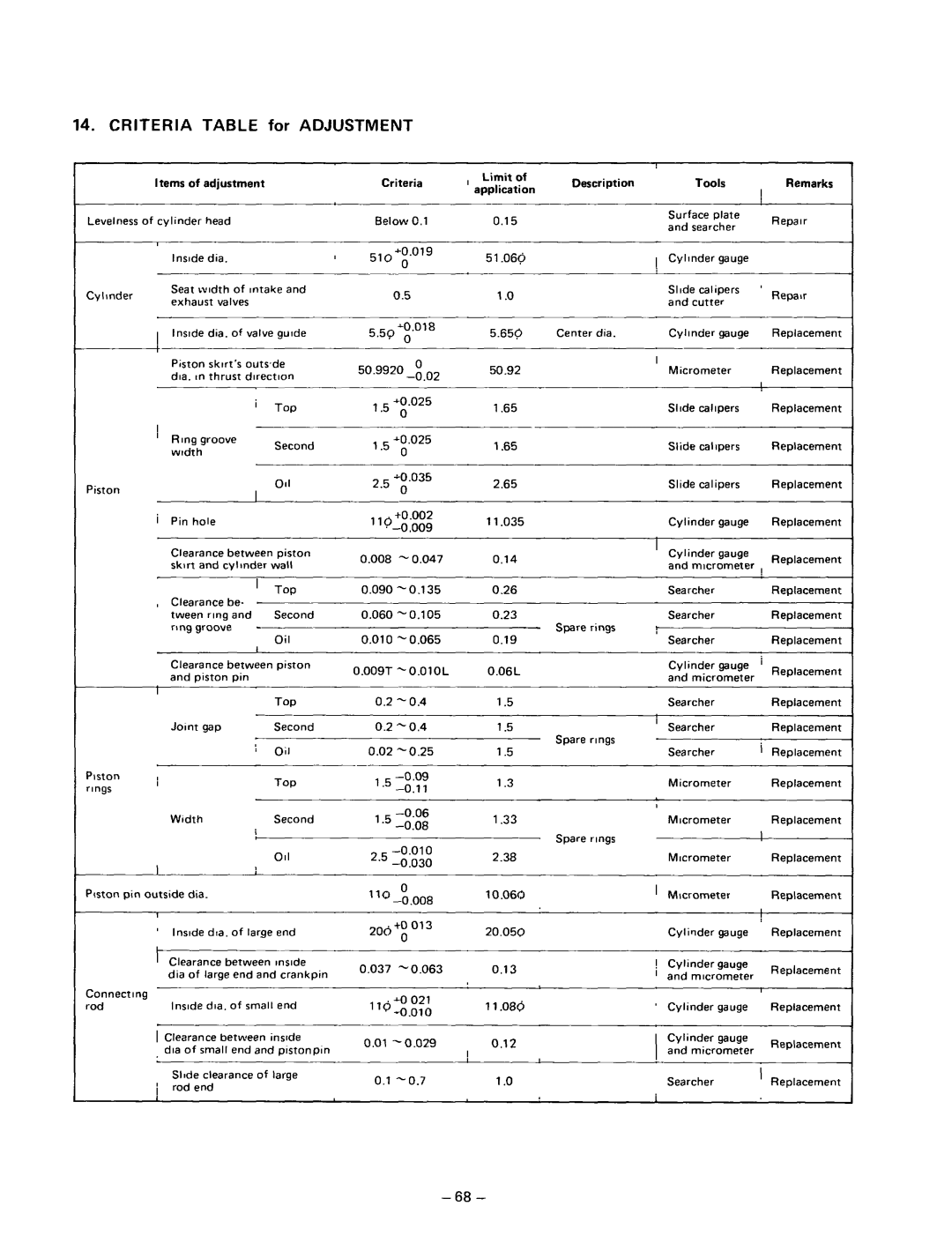

14. CRITERIA TABLE for ADJUSTMENT

I terns | of | adjustment |

| |||

Levelness of cylinder | head |

|

| |||

| lnslde | dia. |

|

| ||

Cylinder | Seat width of Intake and | |||||

exhaust | valves |

|

| |||

|

|

| ||||

1 lnstde dia. of valve guide | ||||||

| Piston | skirt’s | outs,de | |||

| dia. | I” thrust | dIrectIon | |||

|

|

|

|

| ’ | TOP |

I |

|

|

|

|

|

|

’ | Ring | groove |

| Second | ||

| width |

|

|

| ||

|

|

|

|

| ||

Piston |

|

|

|

|

| 011 |

|

|

|

|

|

| |

i | Pin | hole |

|

|

| |

| Clearance | between | piston | |||

| skirt |

| and | cylmder | wall | |

’ Top

,Clearance be-

tween ring and Second

ring groove -

Oil

Clearance between piston and piston pin

I

Criteria

Below 0.1

510+o.o19

0

0.5

5,50A0.018

. 0

0

50.9920

,,5 +0.025 0

,,5 ~0.025 0

2.5ao.035

0

,,O +0.002

0.008 - 0.047

0.090

0.060

0.010

0.009T - O.OlOL

,Limit of application

0.15

51 .cl6Q

1a

5.656

50.92

1.65

1.65

2.65

11 .O35

0.14

0.26

0.23

0.19

0.06L

Description

Center dia.

Spare rings

|

| Tools |

| Remarks | |

| Surface | plate |

| Repalr | |

| and | searcher |

| ||

|

|

| |||

1 | Cylinder | gauge |

|

| |

| Slide | calipers | ’ | Repair | |

| and | cutter |

|

| |

| Cylinder | gauge |

| Replacement | |

I | Micrometer |

| Replacement | ||

| I | ||||

|

|

|

|

| |

| Slide | calipers |

| Replacement | |

| Slide | calipers |

| Replacement | |

| Slide | calipers |

| Replacement | |

| Cylinder | gauge |

| Replacement | |

’ | Cylinder | gauge |

| Replacement | |

| and | mxrometer | , | ||

| Searcher |

|

| Replacement | |

v | Searcher |

|

| Replacement | |

|

|

|

|

| |

’ | Searcher |

|

| Replacement | |

| Winder | Saw | ’ | Replacement | |

| and | micrometer |

|

| |

I

|

|

|

|

|

|

| Top | 0.2 | - | 0.4 |

|

| Joint | gap |

|

| Second | 0.2 | |||

|

|

|

|

|

| I | Oil | 0.02 | ||

Piston | I |

|

|

|

|

| Top | 1.5 | ||

rings |

|

|

|

|

| |||||

|

| Width |

|

|

| Second | ’ .5 | |||

|

|

|

|

|

|

|

|

| ||

A- |

|

|

|

|

|

| 011 | 2,5 | ||

|

|

|

|

|

|

|

| |||

P!ston pin | outside | dia. |

|

|

| “* |

| 0 | ||

|

|

|

|

|

|

|

|

| ||

| ’ | lnstde | d:a. | of | large | end | 20d+0 | 013 | ||

|

|

| 0 | |||||||

|

|

|

|

|

|

|

|

|

| |

| I | Clearance | between | mslde | 0.037 | |||||

|

| dia of large end and crankpin | ||||||||

|

|

|

|

| ||||||

Connecting |

| lnslde | dia. | of | small | end |

| |||

rod |

|

| ||||||||

| ||||||||||

|

|

|

|

|

|

|

| |||

| 1 Clearance between | instde | 0.01 | - | 0.029 | |||||

|

| dla of small end and ptstonpln | ||||||||

|

|

|

|

| ||||||

|

| Slide | clearance | of | large | 0.1 | ||||

| i | rod | end |

|

|

| ||||

|

|

|

|

|

|

| ||||

| 1 |

|

|

|

|

|

|

|

|

|

1.5

1.5

1 .5

1.3

1.33

2.38

10.060

20.050

0.13

11.080

0.12

I

1 .o

Spare rings

Spare rings

Searcher | Replacement |

| Micrometer |

| Replacement | |

| MIcrometer |

| Replacement | |

|

|

| ! |

|

| MIcrometer |

| Replacement | |

’ | MIcrometer |

| Replacement | |

| Cylinder | gauge | Replacement | |

1 | Cylinder | gauge | Replacement | |

| and | mlcrometer | ||

|

| |||

’ | Cylinder | gauge | Replacement | |

| Cylinder | gauge | Replacement | |

| and | micrometer | ||

|

| |||

| Searcher | ’ | Replacement | |

I |

|

|

|

|

I