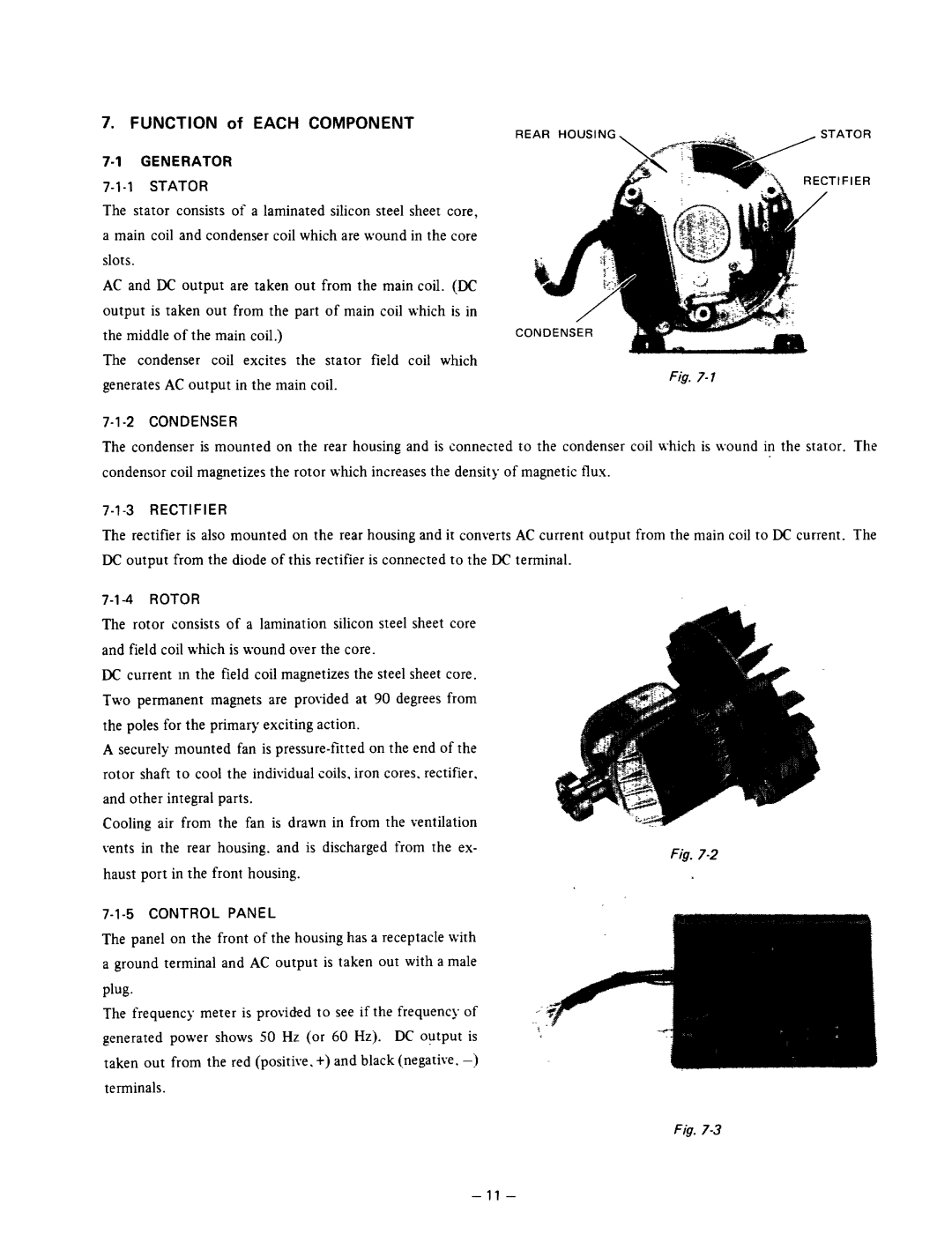

7. FUNCTION of EACH COMPONENT

REAR HOUSING

7-1 GENERATOR

RECTIFIER | |

| |

The stator consists of a laminated silicon steel sheet core, |

|

a main coil and condenser coil which are wound in the core |

|

slots. |

|

AC and DC output are taken out from the main coil. (DC |

|

output is taken out from the part of main coil which is in |

|

the middle of the main coil.) |

|

The condenser coil excites the stator field coil which |

|

generates AC output in the main coil. | Fig. 7- 7 |

|

7-1-2 CONDENSER

The condenser is mounted on the rear housing and is connected to the condenser coil which is wound in the stator. The condenser coil magnetizes the rotor which increases the density of magnetic flux.

7-1-3 RECTIFIER

The rectifier is also mounted on the rear housing and it converts AC current output from the main coil to DC current. The DC output from the diode of this rectifier is connected to the DC terminal.

The rotor consists of a lamination silicon steel sheet core and field coil which is wound over the core.

DC current m the field coil magnetizes the steel sheet core. Two permanent magnets are provided at 90 degrees from the poles for the primary exciting action.

A securely mounted fan is

Cooling air from the fan is drawn in from the ventilation

vents in the rear housing. and is discharged from the ex-

haust port in the front housing.

The panel on the front of the housing has a receptacle with a ground terminal and AC output is taken out with a male

Plug.

Fig.

The frequency meter is provided to see if the frequency of generated power shows 50 Hz (or 60 Hz). DC output is taken out from the red (positive. +) and black (.negative.

Fig.