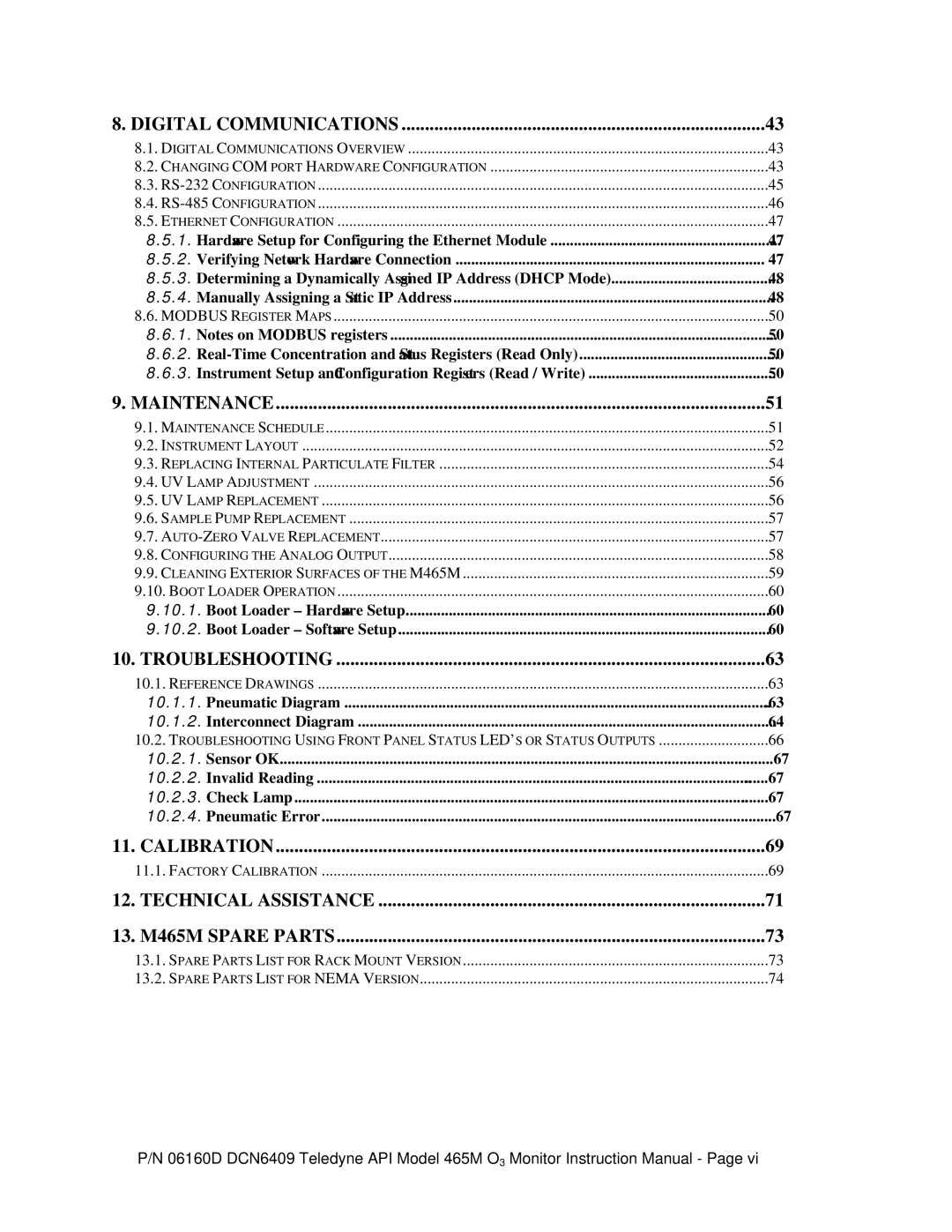

8. DIGITAL COMMUNICATIONS | 43 |

8.1. DIGITAL COMMUNICATIONS OVERVIEW | 43 |

8.2. CHANGING COM PORT HARDWARE CONFIGURATION | 43 |

8.3. | 45 |

8.4. | 46 |

8.5. ETHERNET CONFIGURATION | 47 |

8.5.1. Hardware Setup for Configuring the Ethernet Module | 47 |

8.5.2. Verifying Network Hardware Connection | 47 |

8.5.3. Determining a Dynamically Assigned IP Address (DHCP Mode) | 48 |

8.5.4. Manually Assigning a Static IP Address | 48 |

8.6. MODBUS REGISTER MAPS | 50 |

8.6.1. Notes on MODBUS registers | 50 |

8.6.2. | 50 |

8.6.3. Instrument Setup and Configuration Registers (Read / Write) | 50 |

9. MAINTENANCE | 51 |

9.1. MAINTENANCE SCHEDULE | 51 |

9.2. INSTRUMENT LAYOUT | 52 |

9.3. REPLACING INTERNAL PARTICULATE FILTER | 54 |

9.4. UV LAMP ADJUSTMENT | 56 |

9.5. UV LAMP REPLACEMENT | 56 |

9.6. SAMPLE PUMP REPLACEMENT | 57 |

9.7. | 57 |

9.8. CONFIGURING THE ANALOG OUTPUT | 58 |

9.9. CLEANING EXTERIOR SURFACES OF THE M465M | 59 |

9.10. BOOT LOADER OPERATION | 60 |

9.10.1. Boot Loader – Hardware Setup | 60 |

9.10.2. Boot Loader – Software Setup | 60 |

10. TROUBLESHOOTING | 63 |

10.1. REFERENCE DRAWINGS | 63 |

10.1.1. Pneumatic Diagram | 63 |

10.1.2. Interconnect Diagram | 64 |

10.2. TROUBLESHOOTING USING FRONT PANEL STATUS LED’S OR STATUS OUTPUTS | 66 |

10.2.1. Sensor OK | 67 |

10.2.2. Invalid Reading | 67 |

10.2.3. Check Lamp | 67 |

10.2.4. Pneumatic Error | 67 |

11. CALIBRATION | 69 |

11.1. FACTORY CALIBRATION | 69 |

12. TECHNICAL ASSISTANCE | 71 |

13. M465M SPARE PARTS | 73 |

13.1. SPARE PARTS LIST FOR RACK MOUNT VERSION | 73 |

13.2. SPARE PARTS LIST FOR NEMA VERSION | 74 |

P/N 06160D DCN6409 Teledyne API Model 465M O3 Monitor Instruction Manual - Page vi