9. MAINTENANCE

CAUTION

RISK OF ELECTRICAL SHOCK. THE OPERATIONS

OUTLINED IN THIS CHAPTER ARE TO BE PERFORMED BY

QUALIFIED MAINTENANCE PERSONNEL ONLY!

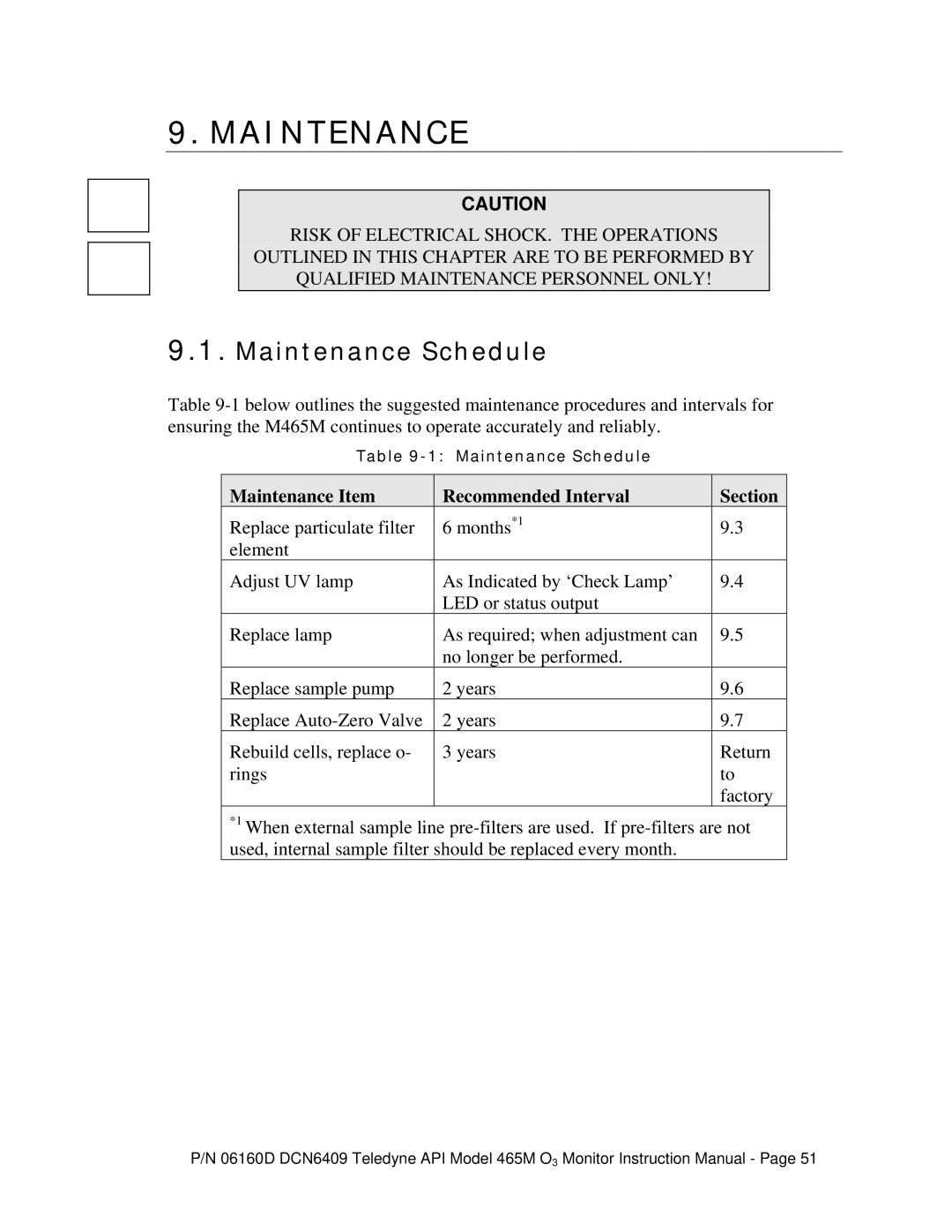

9.1.Maintenance Schedule

Table

Table

Maintenance Item | Recommended Interval | Section |

Replace particulate filter | 6 months*1 | 9.3 |

element |

|

|

Adjust UV lamp | As Indicated by ‘Check Lamp’ | 9.4 |

| LED or status output |

|

Replace lamp | As required; when adjustment can | 9.5 |

| no longer be performed. |

|

Replace sample pump | 2 years | 9.6 |

Replace | 2 years | 9.7 |

Rebuild cells, replace o- | 3 years | Return |

rings |

| to |

|

| factory |

*1 When external sample line

P/N 06160D DCN6409 Teledyne API Model 465M O3 Monitor Instruction Manual - Page 51