MAINTENANCE

GREASING INNER AND OUTER DRAFT BEAM

PIVOT POINTS

Locate the grease zerks on the inner and outer draft beam pivot bosses. Inject Lithium-Complex Extreme Pressure grease conforming to NLGI2-ISO 320 specifications into each zerk until grease protrudes from joints. Grease all pivots daily or every 8 hours of service.

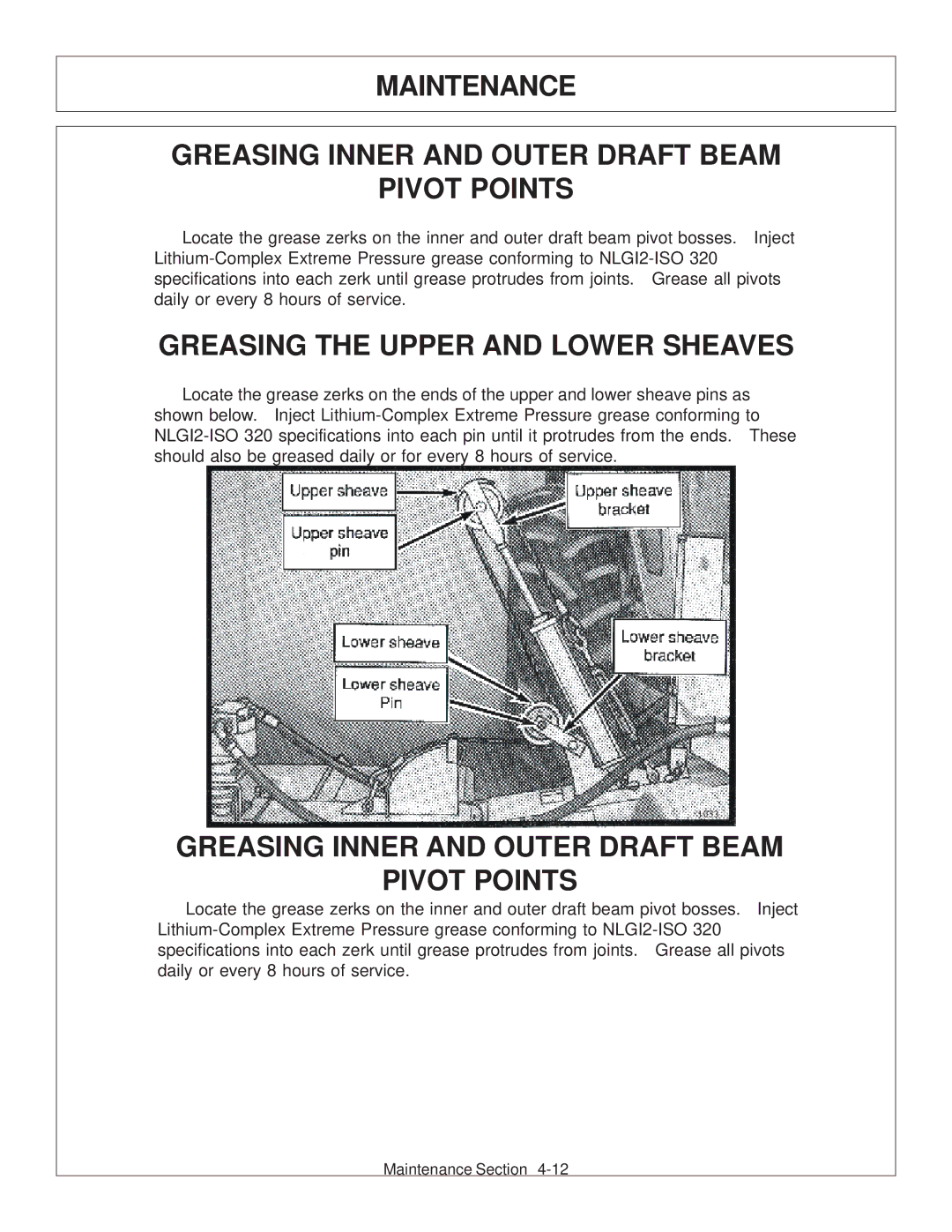

GREASING THE UPPER AND LOWER SHEAVES

Locate the grease zerks on the ends of the upper and lower sheave pins as shown below. Inject Lithium-Complex Extreme Pressure grease conforming to NLGI2-ISO 320 specifications into each pin until it protrudes from the ends. These should also be greased daily or for every 8 hours of service.

GREASING INNER AND OUTER DRAFT BEAM

PIVOT POINTS

Locate the grease zerks on the inner and outer draft beam pivot bosses. Inject Lithium-Complex Extreme Pressure grease conforming to NLGI2-ISO 320 specifications into each zerk until grease protrudes from joints. Grease all pivots daily or every 8 hours of service.