MAINTENANCE

BEARING ADJUSTMENT

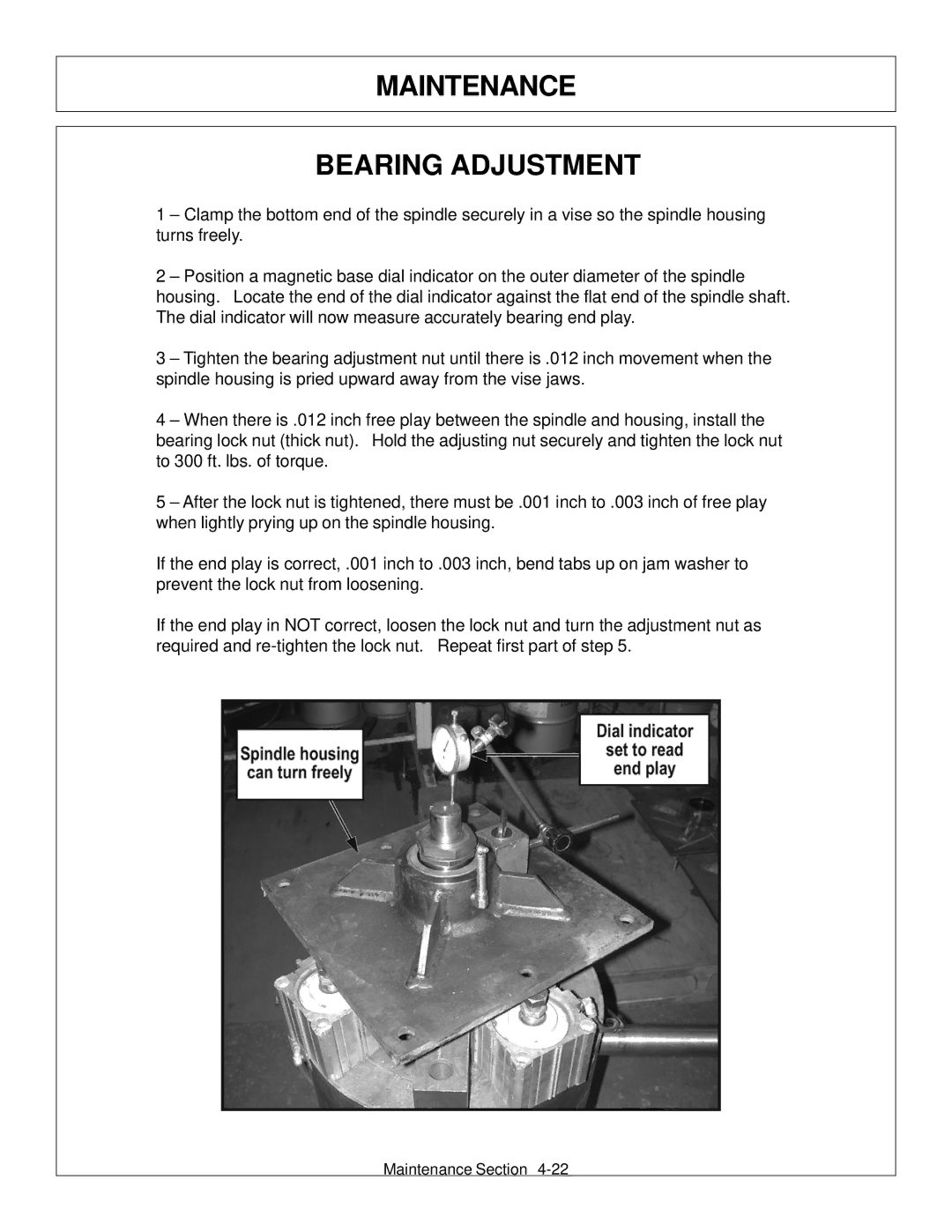

1 – Clamp the bottom end of the spindle securely in a vise so the spindle housing turns freely.

2 – Position a magnetic base dial indicator on the outer diameter of the spindle housing. Locate the end of the dial indicator against the flat end of the spindle shaft. The dial indicator will now measure accurately bearing end play.

3 – Tighten the bearing adjustment nut until there is .012 inch movement when the spindle housing is pried upward away from the vise jaws.

4 – When there is .012 inch free play between the spindle and housing, install the bearing lock nut (thick nut). Hold the adjusting nut securely and tighten the lock nut to 300 ft. lbs. of torque.

5 – After the lock nut is tightened, there must be .001 inch to .003 inch of free play when lightly prying up on the spindle housing.

If the end play is correct, .001 inch to .003 inch, bend tabs up on jam washer to prevent the lock nut from loosening.

If the end play in NOT correct, loosen the lock nut and turn the adjustment nut as required and

Maintenance Section