MAINTENANCE

With the cutter head lowered, locate the grease zerks on the linkage and pivot bosses. Inject

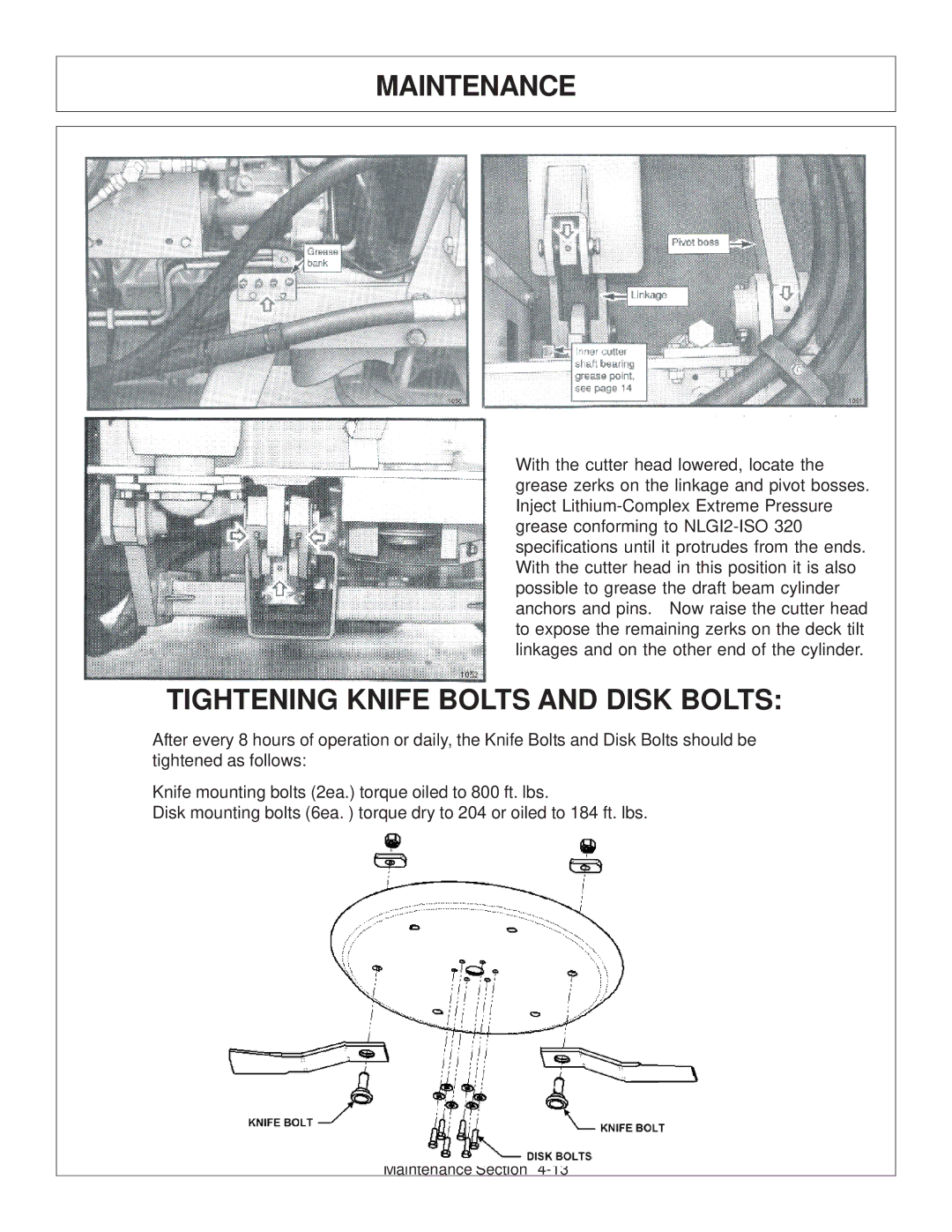

TIGHTENING KNIFE BOLTS AND DISK BOLTS:

After every 8 hours of operation or daily, the Knife Bolts and Disk Bolts should be tightened as follows:

Knife mounting bolts (2ea.) torque oiled to 800 ft. lbs.

Disk mounting bolts (6ea. ) torque dry to 204 or oiled to 184 ft. lbs.

Maintenance Section