Specifications

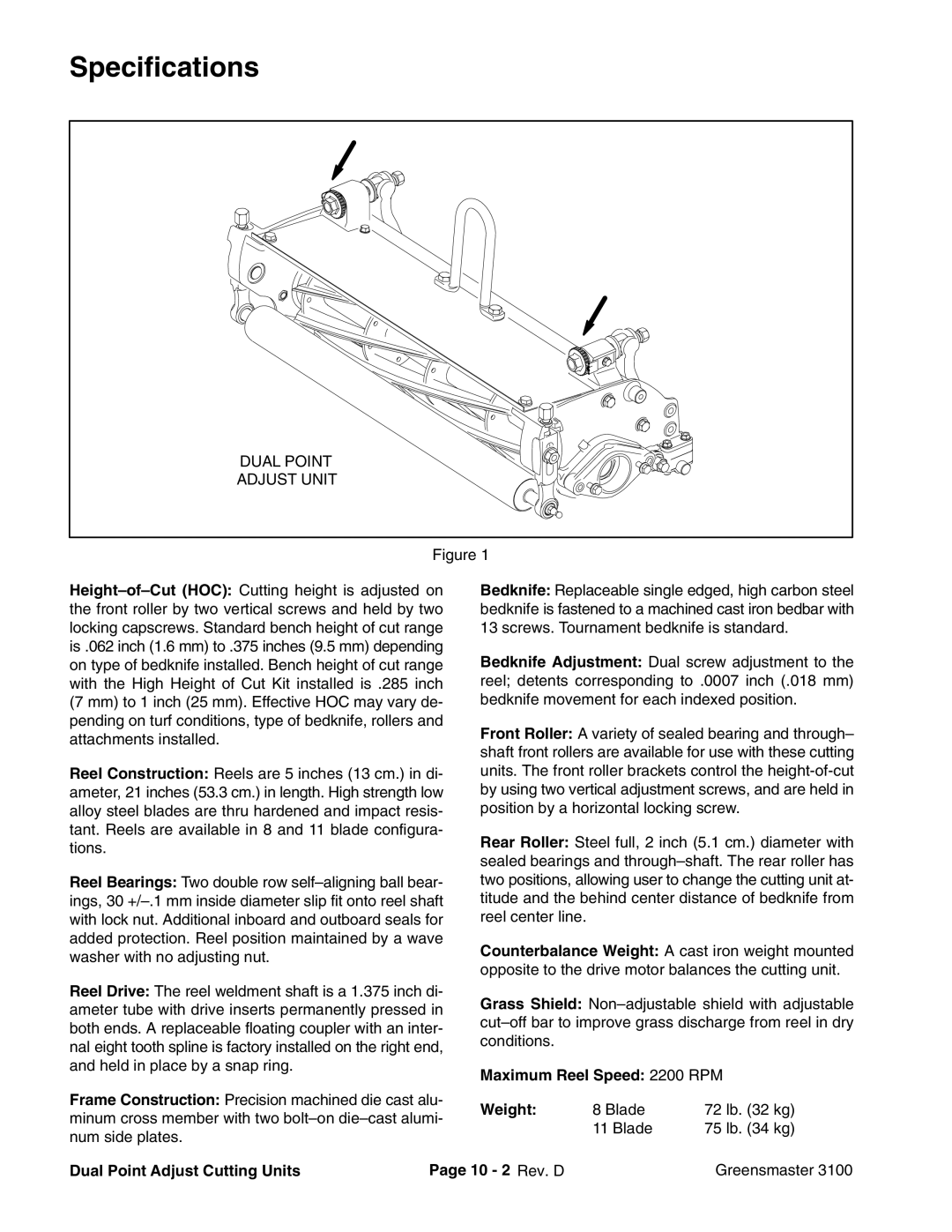

DUAL POINT

ADJUST UNIT

| Figure 1 |

|

| ||

Bedknife: Replaceable single edged, high carbon steel | |||||

the front roller by two vertical screws and held by two | bedknife is fastened to a machined cast iron bedbar with | ||||

locking capscrews. Standard bench height of cut range | 13 screws. Tournament bedknife is standard. | ||||

is .062 inch (1.6 mm) to .375 inches (9.5 mm) depending | Bedknife Adjustment: Dual screw adjustment to the | ||||

on type of bedknife installed. Bench height of cut range | |||||

with the High Height of Cut Kit installed is .285 inch | reel; detents corresponding to .0007 inch (.018 mm) | ||||

(7 mm) to 1 inch (25 mm). Effective HOC may vary de- | bedknife movement for each indexed position. | ||||

pending on turf conditions, type of bedknife, rollers and | Front Roller: A variety of sealed bearing and through– | ||||

attachments installed. |

| ||||

| shaft front rollers are available for use with these cutting | ||||

|

| ||||

Reel Construction: Reels are 5 inches (13 cm.) in di- | units. The front roller brackets control the | ||||

ameter, 21 inches (53.3 cm.) in length. High strength low | by using two vertical adjustment screws, and are held in | ||||

alloy steel blades are thru hardened and impact resis- | position by a horizontal locking screw. | ||||

tant. Reels are available in 8 and 11 blade configura- | Rear Roller: Steel full, 2 inch (5.1 cm.) diameter with | ||||

tions. |

| ||||

| sealed bearings and | ||||

|

| ||||

Reel Bearings: Two double row | two positions, allowing user to change the cutting unit at- | ||||

ings, 30 | titude and the behind center distance of bedknife from | ||||

with lock nut. Additional inboard and outboard seals for | reel center line. |

|

| ||

added protection. Reel position maintained by a wave | Counterbalance Weight: A cast iron weight mounted | ||||

washer with no adjusting nut. |

| ||||

| opposite to the drive motor balances the cutting unit. | ||||

|

| ||||

Reel Drive: The reel weldment shaft is a 1.375 inch di- | Grass Shield: | ||||

ameter tube with drive inserts permanently pressed in | |||||

both ends. A replaceable floating coupler with an inter- | |||||

conditions. |

|

| |||

nal eight tooth spline is factory installed on the right end, |

|

| |||

|

|

| |||

and held in place by a snap ring. |

| Maximum Reel Speed: 2200 RPM | |||

|

| ||||

Frame Construction: Precision machined die cast alu- | Weight: | 8 Blade | 72 lb. (32 kg) | ||

minum cross member with two | |||||

| 11 Blade | 75 lb. (34 kg) | |||

num side plates. |

|

| |||

|

|

|

| ||

Dual Point Adjust Cutting Units | Page 10 - 2 Rev. D |

| Greensmaster 3100 | ||