Greensmaster 3100/3050

Preface

This page is intentionally blank

Table Of Contents

This page is intentionally blank

Safety Instructions

Safety Instructions

Chapter

Before Operating

Safety Instructions Greensmaster

While Operating

Safety Instructions

Safety Instructions Greensmaster

Product Records

2 1 Rev.. DB Product Records

Equivalents and Conversions

Decimal and Millimeter Equivalents

To Metric Conversions

Equivalents and Conversions Greensmaster

Torque Specifications

Torque Specifications

Capscrew Markings and Torque Values U.S. Customary

Capscrew Markings and Torque Values Metric

This page is intentionally blank

Specification

Specifications

3 1 Rev. D Specifications

Adjustments

Throttle Control Adjustment Fig

Choke Control Adjustment Fig

Adjustments Greensmaster

Governor Adjustment Before starting engine

Governor Lever Adjustment Fig

Throttle Restrictor Adjustment Fig

Secondary Spring Adjustments Fig

Carburetor and Speed Control Adjustment

Warnin G

Installing the Engine

Engine Removal and Installation

Removing the Engine

Engine Removal and Installation Greensmaster

Table of Contents

Hydraulic System

Specifications 4 2 Rev. D

Description

Hydraulic Fitting Installation

General Information

Hydraulic Hoses

Ring Face Seal

SAE Straight Thread O-Ring Port Adjustable

SAE Straight Thread O-Ring Port Non-adjustable Fig

General Information Greensmaster

Hydraulic Flow Diagrams

Traction, No Position

Hydraulic Flow Diagrams Greensmaster

Traction, Reverse Position

Hydraulic Flow Diagrams 4 8 Rev. E Greensmaster3100

Reel Drive, Mowing Operation

Reel Drive, Lower Cutting Units

4 9 Rev. E

Hydraulic Flow Diagrams 4 10 Rev. E

Reel Drive, Raising Cutting Units

Power Steering, R.H. Turn Greensmaster

4 11 Rev. E

Hydraulic Schematic Greensmaster 3100 2WD Serial

Hydraulic Schematics

Rev. E

Hydraulic Schematic Greensmaster 3100 3WD

Hydraulic Schematics 4 12.2 Rev. E

Hydraulic Schematic

12.3

Hydraulic Schematics 4 12.4 Rev. E Greensmaster

Special Tools

Hydraulic Tester Fig

Seal Protector Fig

Detent Installation Tool Fig

Special Tools Greensmaster

Assembly Studs Fig

Seal Installation Tool Fig

Control Valve Spool Seal Installation Tools Fig

Troubleshooting

Troubleshooting Greensmaster

Troubleshooting

Slow Groundspeed in All Traction Selections

Slow or No Ground Speed in No and Reverse No Appears Normal

No Increase in Speed from No to No

One or More Cutting Units Slow or No Reel Drive Action

All Reels Slow or Will Not Turn

Mow Pedal Won’t Stay Engaged Reels Slow Down or Stop

Cutting Units Drop During Transport

Cutting Units Lift Too Slowly or Not At All

Lift Pedal Binding

Center #1 Cutting Unit Operates in Raised Position

Steering Loss, Steering Wander or Free Play

Testing

Testing

Engine when the traction lever is engaged

Traction Pump Flow Traction Relief Setting

Testing Greensmaster

Test B Relief Valve Setting Procedure

Test Hook UP no

4 30 Rev. E Testing

Test Hook UP NO.2

Testing 4 31 Rev. E Greensmaster

Test Hook UP NO.2

Testing 4 32 Rev. E Greensmaster3100

Engine when the mow pedal is engaged

Reel Drive Pump Efficiency

Test a Reel Drive Motor Flow Procedure

4 33 Rev. E Testing

Test Hook UP no

Test Hook UP no Greensmaster

4 35 Rev. E Testing

Steering Pump Flow and Relief Pressure

Lift and Mow Pedal Height Adjustment Fig

Traction Pedal Adjustment Fig

4 37 Rev. B Adjustments

Traction Return Linkage a

Reverse

Rear Camshaft Adjustment Fig

Reel Motor Removal and Installation Fig

Reel Motor Shaft Seal Replacement Fig

Repairs

Repairs

Reel Motor 70-9800 Repair Fig

Repairs 4 40 Rev. B

Repairs

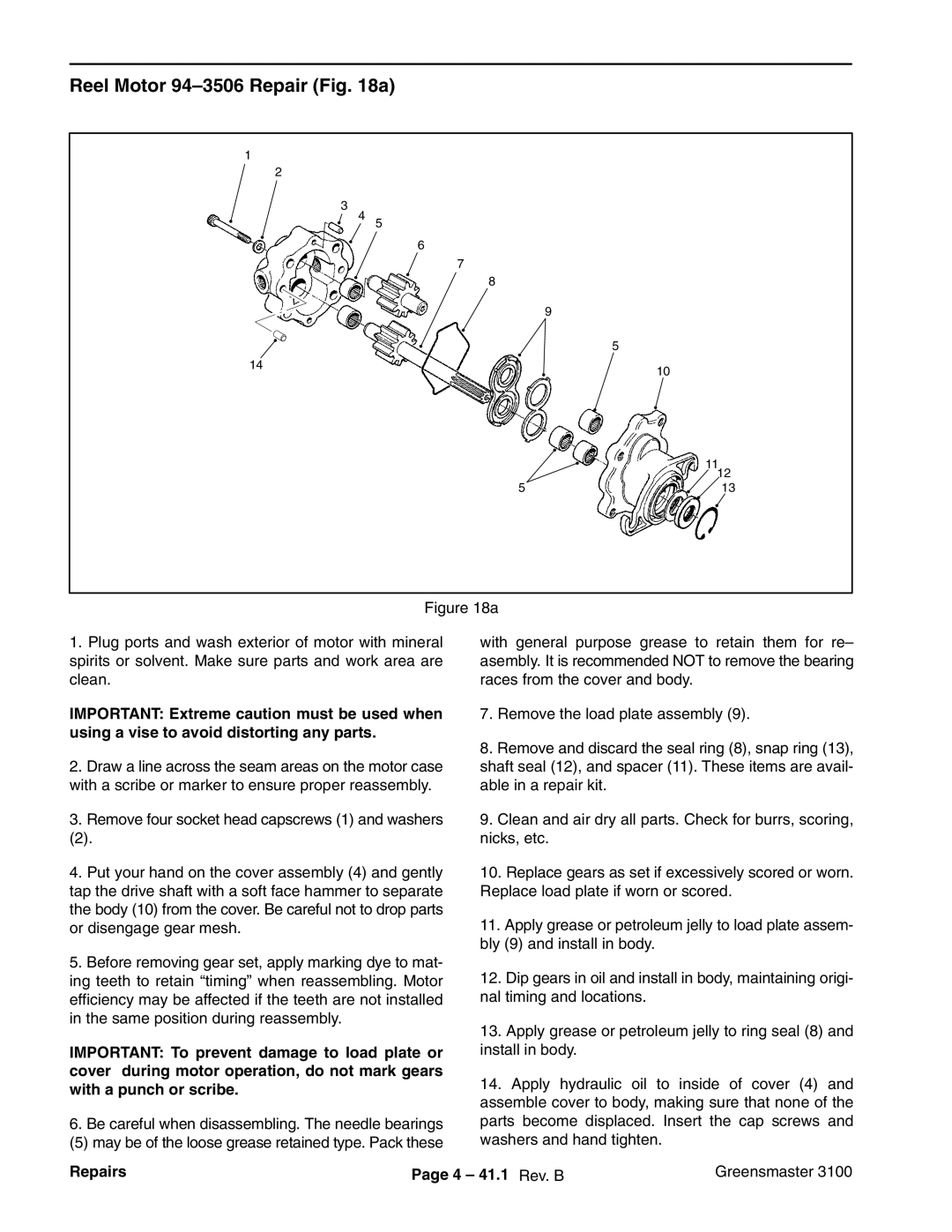

Reel Motor 94-3506 Repair a

Repairs 4 41.1 Rev. B Greensmaster

Greensmaster 4-41.2 Rev. B Repairs

Reel Motor 105-9770 Repair b

Disassembly

Repairs 4 41.3 Rev. D Greensmaster

Inspection

Greensmaster 4-41.4 Rev. D Repairs

Reassembly

Repairs 4 41.5 Rev. D Greensmaster

This page is intentionally blank

Repairs Greensmaster

Pump Repair Greensmaster 3100 shown Fig Relief Valve Service

Repairs Greensmaster

Relief Valve Removal and Installation Fig

Control Valve Removal and Installation Fig

Greensmaster Repairs

Control Valve Spool Seal Replacement

Rear Bonnet Side Fig

Control Valve Internal Seal Replacement Fig

Control Valve No Spool Detent Replacement

Control Valve No Spool Detent Replacement Fig

Reassemble With the Following Procedures

Lift Cylinder Removal and Installation

No Center Lift Cylinder Fig

No and 3 Lift Cylinders Fig

Lift Cylinder Repair No Center Fig

Lift Cylinder Repair No and 3 Left and Right Fig

Wheel Motor Removal and Installation Fig

Disassembly of Motor Fig

Wheel Motor Repair

Assembly of Motor

Before Assembling Motor

Rotor, Stator and Vane Assembly

Reverse steps 1 3 to install the steering cylinder

Steering Cylinder Repair Greensmaster 3100 Fig

Repairs Greensmaster

Steering Control Unit Repair Greensmaster 3100 Fig

Meter Gerotor End Disassembly

Control End Disassembly

Push pin from spool and sleeve assembly

Repairs

Control End Reassembly

Repairs

Repairs Greensmaster

Repairs

Repairs Greensmaster

Repairs

Repairs Greensmaster

Electrical System

Wiring Schematic Greensmaster 3100, S/N Below

Wiring Schematics 5 2 Rev. D Greensmaster

Wiring Schematics

Wiring Schematic Greensmaster 3100, S/N 80001

5 2.1 Rev. D

Wiring Schematic

Greensmaster 3100, S/N

220999999

5 2.2 Rev. D

Wiring Schematic

Wiring Schematic Greensmaster 3050, S/N Below

Wiring Schematics 5 2.4 Rev. D Greensmaster 3100/3050

Wiring Schematic Greensmaster 3050, S/N 80001

5 2.5 Rev. D Wiring Schematics

Wiring Schematic Greensmaster 3050, S/N 230000001 and Up

Wiring Schematics 5 2.6 Rev. D

3100/3050

200999999

This page is intentionally blank

Normal Operation Warm Oil

Before Start-Up Cold Oil

Leak Alert

Continuity Tester Fig

Volt Ohm Amp Meter Fig

Skin-Over Grease Fig

Condition Cause Correction

Problem Cause Correction

Verify Interlock Operation

Ignition Key Switch Fig

Seat Switch Fig

Traction Neutral Switch Fig

Mow/Lift Switch Fig

Interlock Module Fig

Hourmeter

Battery

Turf Guardian TM Leak Detector System

General Safety Interlock Switch Service

Seat Switch Replacement and Adjustment Fig

Traction Neutral Switch Replacement and Adjustment Fig

Mow/Lift Switch Replacement and Adjustment Fig

Wiring Harness Service

Battery Service

Battery Specifications

Wheels, Steering and Brakes

6 1 Rev. B

Specifications Greensmaster

Brake Adjustment Fig

Brake Service Fig

Brake Disassembly Reassembly

Steering Cable Greensmaster

Steering Arm Greensmaster

6 5 Rev. B Repairs

Repairs 6 6 Rev. B Greensmaster

Bolt Adjust Cutting Units

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut Rev. C

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut Rev. C

Page

Single Point Adjust Cutting Units

Page

Page

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut threads Rev. C

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut threads Rev. C

Page

Page

Introduction

For Four Bolt Adjust and Single Point Adjust Cutting Units

9 1 Rev. D Introduction

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut threads Rev. C

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Use Loctite 271 on spline nut threads Rev. C

Page

Page

Page

Page

Page

Page

This page is intentionally blank

Dual Point Adjust Cutting Units

10 1 Rev. D Dual Point Adjust Cutting units

Dual Point Adjust Cutting Units 10 2 Rev. D

Weight

Maximum Reel Speed 2200 RPM

Gauge Bar Assembly

Backlapping Brush Assembly

10 3 Rev. D Dual Point Adjust Cutting units

Bedknife Screw Tool

Inner Grease Seal Installation Washer

Dual Point Adjust Cutting Units 10 4 Rev. D Greensmaster

Plastic Plug

Turf Evaluator Tool

Factor Possible Problem/Correction

After installation to the bedbar

10 5 Rev. D Dual Point Adjust Cutting units

Factors That Can Affect Quality of Cut

Dual Point Adjust Cutting Units 10 6 Rev. D Greensmaster

Characteristics

Set Up and Adjustments

10 7 Rev. D Dual Point Adjust Cutting units

Installation

Dual Point Adjust Cutting Units 10 8 Rev. D Greensmaster

Hydraulic Reel Motor

Removal

10 9 Rev. D Dual Point Adjust Cutting units

To Avoid Personal Injury or Death

Bedbar Assembly

Dual Point Adjust Cutting Units 10 10 Rev. D Greensmaster

Bedbar Removal and Installation

Installation Fig

10 11 Rev. D Dual Point Adjust Cutting units

Removal Fig

Bedbar Adjuster Service

Dual Point Adjust Cutting Units 10 12 Rev. D Greensmaster

Bedknife Replacement and Grinding

Replacement

10 13 Rev. D Dual Point Adjust Cutting units

Grinding

Reel Assembly

Dual Point Adjust Cutting Units 10 14 Rev. D Greensmaster

10 15 Rev. D Dual Point Adjust Cutting units

Reel Removal Fig

Right Side Plate Service Fig

Left Side Plate Service Fig

Dual Point Adjust Cutting Units 10 16 Rev. D Greensmaster

Reel Service Fig

10 17 Rev. D Dual Point Adjust Cutting units

Reel Installation Fig

Dual Point Adjust Cutting Units 10 18 Rev. D Greensmaster

10 19 Rev. D Dual Point Adjust Cutting units

Preparing a Reel for Grinding

Front Roller Removal and Installation

Dual Point Adjust Cutting Units 10 20 Rev. D Greensmaster

Front and Rear Roller Service

Seal Installation

10 21 Rev. D Dual Point Adjust Cutting units

Seal Removal

Dual Point Adjust Cutting Units 10 22 Rev. D Greensmaster

Bearing Installation

Bearing Removal

This page is intentionally blank

Commercial Products