Blower Coil Air Handler

April

Environmental Concerns

Refrigerant warning information

Responsible Refrigerant Practices

Hazard of Explosion and Deadly Gases

About This Manual

Trademarks

Table of Contents

BCXC-SVX01B-EN

Digits 5, 6, 7 Unit Size

Digit 16 Motor Horsepower

Digits 1, 2, 3, 4 Unit Model

Digit 8 Unit Voltage

Model Number Description

General Information

Blower Coil General Information

General Information

Receiving and Handling

Pre-Installation

Jobsite Storage Recommendations

Pre-Installation

Installation Preparation

Service Access

Unit size Dimension a

Improper Unit Lift

Unit Handling Procedure

Rigging and Handling

Unit Location Recommendations

Pre-Installation Checklist

Skid Removal

Unit Size RH LH Weight

Dimensions and Weights

Horizontal blower coil dimensions in. and weights lb

Horizontal Blower Coil

Unit Size Weight

Dimensions and Weights

Vertical blower coil dimensions in. and weights lb

Vertical Blower Coil

Angle Filter and Mixing Box

Angle filter and mixing box dimensions in. and weights lb

Unit size

Bottom or Top Access Filter Box

AIR Flow Filter Filter Access Panel

Electric heat dimensions in. and weights lb

Electric Heat

Coil Connections, NPT

Steam coil box dimensions in. and weights lb

Steam Coil

Supply Return

DX coil connection sizes, OD

Coil Connections

Hydronic coil connection sizes, OD

Steam coil connection sizes, female connection, NPT

Piping Packages

Basic Piping

Dimensions and Weights Deluxe Piping

Piping Nominal

Actual size

Zone Sensor Installation

Installation Controls

Installing Wall Mounted Controls

Wiring Instructions

Service Communication Wiring

Communication Wiring

Installation Controls

Zone Sensors Without Interconnecting Wiring

Tracer Summit Communication Wiring

Installation Electrical

Wire size range Max. wiring distance

Installation Electrical

Zone sensor maximum wiring distances, ft m

Electrical Grounding Restrictions Hazardous Voltage

Available electric heat, min-max kW

Useful Formulas

Unit size Voltage

Motor electrical data

190/50/3

220/50/1

240/50/1

380/50/3

Bchc Installation Procedure

Installation Mechanical

Installing the Unit

Horizontal Units, Model Bchc

Installation Mechanical

Vertical Units, Model Bcvc

Heating Coil Option

Mixing Box Option

Linkage Installation Procedure

Mixing Box Installation Procedure

Condensate Drain Connections

Recommended drain trap installation for draw-through units

Duct Connections

Potential coil-freeze condition

Installation Piping

Water Coil Connections

Refrigerant Coil Piping

Valve Damage

Installation Piping

Suction Line

Field-Installing Evaporator Piping

Field-installed evaporation piping example

General

Steam Piping

Coil Condensate

Steam Coils

Type NS steam coils, horizontal tubes for horizontal airflow

Control Options

Controls Interface

Tracer Controllers

Tracer controller input/output summary

Rover Service Software

Controls Interface

Tracer controller ZN010 ZN510 ZN520

End Device Option Availability

Tracer controller function summary

Tracer Control Device ZN010 Tracer ZN510 Tracer ZN520

Receiving

Pre-Start Checklist

Pre-Start

Unit Location

Unit Piping

Pre-Start Component Overview

Ductwork

Electrical

Sequence of Operation

Start-Up

Tracer ZN Controller Sequence of Operation

Sensor type Sensor position Unit occupancy mode

Occupied Mode

Unoccupied Mode

Start-Up

Cooling Operation

Occupied Standby Mode Tracer ZN510 or ZN520 only

Occupied Bypass Mode, Tracer ZN510 or ZN520 Only

Discharge Air Tempering Tracer ZN520 Only

Start-Up Economizer Cooling Tracer ZN520 Only

DX Cooling Tracer ZN520 only

Heating Operation

Auto fan operation Fan speed default

Fan Mode Operation Rotating Components

Tracer ZN520 fan configuration

Fan sequence of operation

Tracer ZN520

Fan Speed Switch

Tracer ZN010 and ZN510

Continuous Fan Operation

Start-Up Fan Cycling Operation

Fan Off Delay

Fan mode operation, Tracer ZN010 and ZN510

Fan Start on High Speed

Two- and Four-Pipe Changeover Operation

Entering Water Temperature Sampling Function

Local fan switch enabled

Fan operation in heating and cooling modes

Electric Heat Operation

Unit mode as related to water temperature

Unit type EWT sensor required? Coil water temperature

Economizer Damper Tracer ZN520 Only

Data Sharing Tracer ZN510 or ZN520 Only

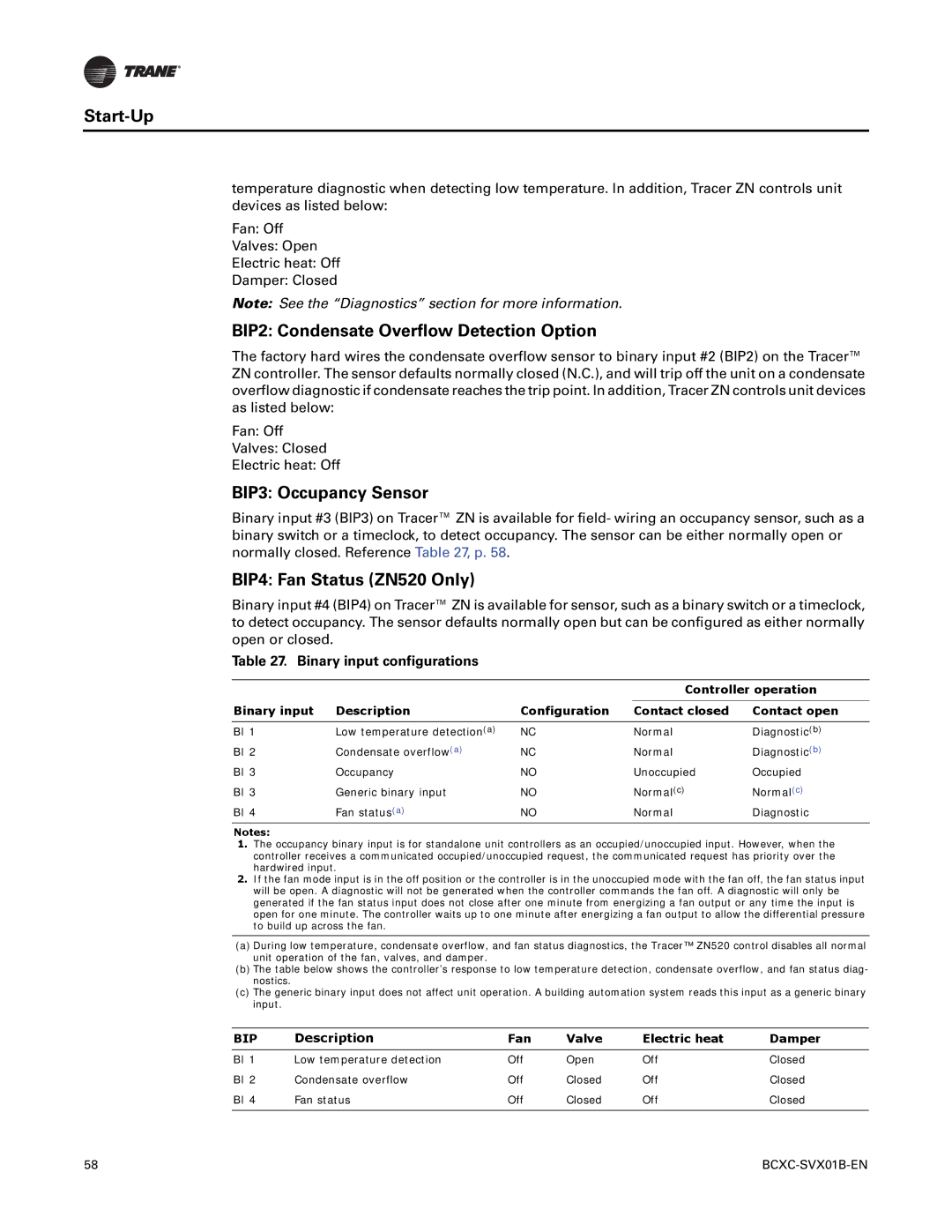

BIP1 Low Temperature Detection Option

Tracer Dehumidification Tracer ZN520 Only

Binary Inputs

BIP3 Occupancy Sensor

Binary input configurations

BIP2 Condensate Overflow Detection Option

BIP4 Fan Status ZN520 Only

Analog inputs

Analog Inputs

Binary Outputs

Analog input Terminal Function Range ZN010 ZN510 ZN520

Zone sensor wiring connections

Space Temperature Measurement

Binary output configuration

Zone Sensor

Fan Switch

Fan Mode Switch

External Setpoint Adjustment

Local Setpoint

On/Cancel Buttons

Communication Jack

Maintenance

Maintenance Procedures

Fan Belt Tension

Maintenance

Fan Assembly Set Screws

Torque in.-lb Ft-lb

Belt tension

BCBH/BCVC valve package waterflow limits

Hydronic coil data

BCHC/BCVC coil general data

Row coil

Steam coil data

Unit Motor Motor sheave Fan sheave Belt

Drive data

1750 1450 Size Watts Browning Trane 60 Hz 50 Hz

Inspecting and Cleaning Coils

Coil Maintenance

Potential unit damage from coil cleaners

Steam, Hot Water, and Cooling Coil Cleaning Procedure

Periodic Maintenance Checklists

Rotating parts

Maintenance

Troubleshooting

Diagnostics

LED Activity

Manual Output Test Procedure

Diagnostics

Manual Output Test

Tracer ZN520 test sequence

Diagnostics

Translating Multiple Diagnostics

Fan Cool output a Heat output Damper Steps J1-1, J1-3

Resetting Diagnostics

Automatic Reset by the Controller

Rover Service Tool

Diagnostics Manual Output Test

Cycling Power

Diagnostic Reset Tracer ZN510 or ZN520 Only

Diagnostic Latching Fan Valves Electric heat Damper

Tracer ZN010 and ZN510 controller diagnostics

Tracer ZN520 diagnostics

Diagnostic Fan Other outputsa

Valves stay closed

Common Diagnostics

Fan outputs do not energize

Probably cause Explanation

Electric heat not operating

Valves stay open

Fresh air damper stays closed

Fresh air damper stays open

DX or electric outputs do not energize

Wiring Diagrams

Two-Pipe Bcxc with Tracer ZN510

Wiring Diagrams

Four-Pipe Bcxc with Tracer ZN510

Four-Pipe Bcxc with Tracer ZN510

Two-Pipe Bcxc with Tracer ZN520

Four-Pipe Bcxc with Tracer ZN520

Four-Pipe Bcxc with Tracer ZN520

Four-Pipe Bcxc with Tracer ZN520

Four-Pipe Bcxc with Control Interface

Four-Pipe Bcxc with Control Interface

Field Installed Device

Bcxc with DX Coil and Tracer ZN520

Bcxc with DX Coil, Hydronic Heating, and Tracer ZN520

BCXC-SVX01B-EN