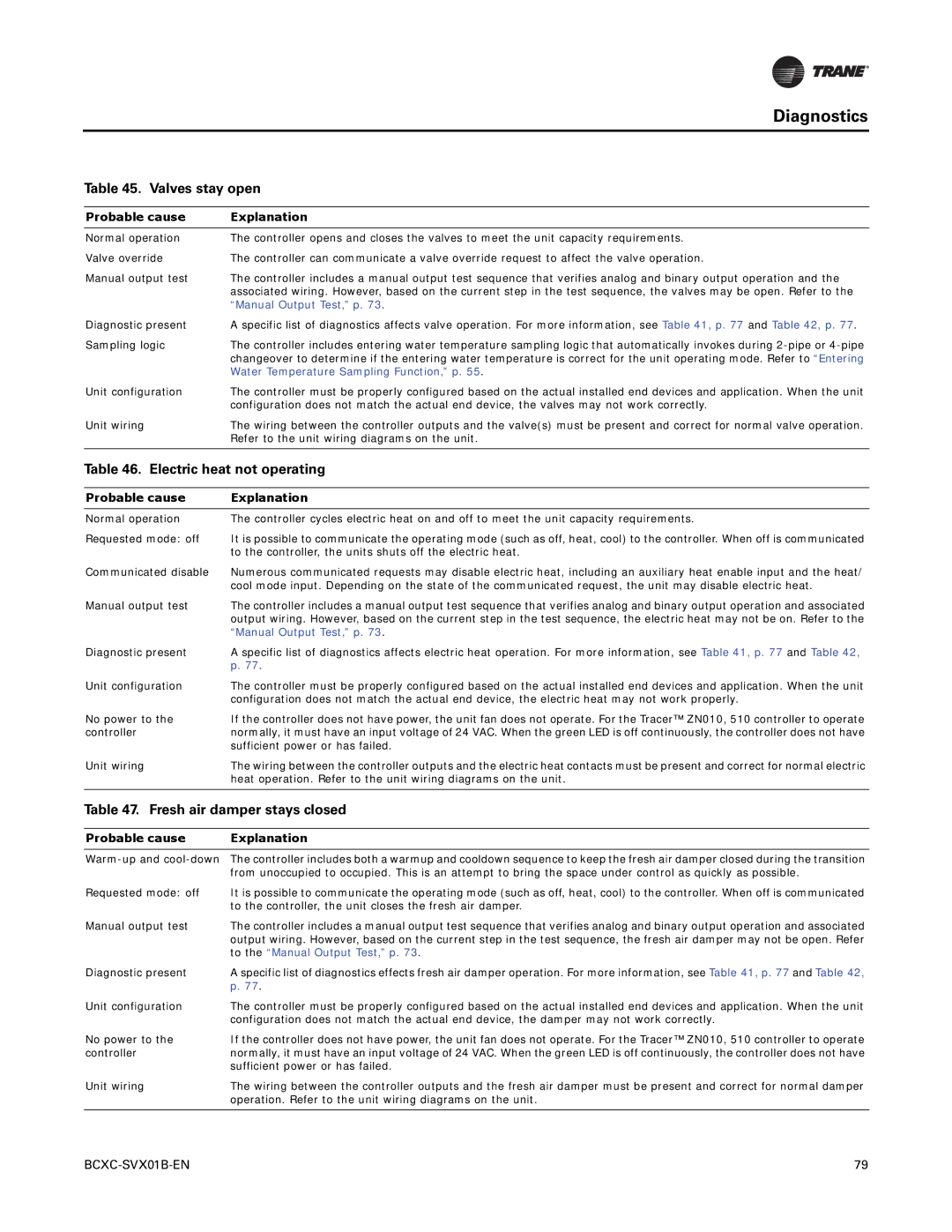

| Diagnostics |

Table 45. Valves stay open | |

|

|

Probable cause | Explanation |

|

|

Normal operation | The controller opens and closes the valves to meet the unit capacity requirements. |

Valve override | The controller can communicate a valve override request to affect the valve operation. |

Manual output test | The controller includes a manual output test sequence that verifies analog and binary output operation and the |

| associated wiring. However, based on the current step in the test sequence, the valves may be open. Refer to the |

| “Manual Output Test,” p. 73. |

Diagnostic present | A specific list of diagnostics affects valve operation. For more information, see Table 41, p. 77 and Table 42, p. 77. |

Sampling logic | The controller includes entering water temperature sampling logic that automatically invokes during |

| changeover to determine if the entering water temperature is correct for the unit operating mode. Refer to “Entering |

| Water Temperature Sampling Function,” p. 55. |

Unit configuration | The controller must be properly configured based on the actual installed end devices and application. When the unit |

| configuration does not match the actual end device, the valves may not work correctly. |

Unit wiring | The wiring between the controller outputs and the valve(s) must be present and correct for normal valve operation. |

| Refer to the unit wiring diagrams on the unit. |

| |

Table 46. Electric heat not operating | |

|

|

Probable cause | Explanation |

|

|

Normal operation | The controller cycles electric heat on and off to meet the unit capacity requirements. |

Requested mode: off | It is possible to communicate the operating mode (such as off, heat, cool) to the controller. When off is communicated |

| to the controller, the units shuts off the electric heat. |

Communicated disable | Numerous communicated requests may disable electric heat, including an auxiliary heat enable input and the heat/ |

| cool mode input. Depending on the state of the communicated request, the unit may disable electric heat. |

Manual output test | The controller includes a manual output test sequence that verifies analog and binary output operation and associated |

| output wiring. However, based on the current step in the test sequence, the electric heat may not be on. Refer to the |

| “Manual Output Test,” p. 73. |

Diagnostic present | A specific list of diagnostics affects electric heat operation. For more information, see Table 41, p. 77 and Table 42, |

| p. 77. |

Unit configuration | The controller must be properly configured based on the actual installed end devices and application. When the unit |

| configuration does not match the actual end device, the electric heat may not work properly. |

No power to the | If the controller does not have power, the unit fan does not operate. For the Tracer™ ZN010, 510 controller to operate |

controller | normally, it must have an input voltage of 24 VAC. When the green LED is off continuously, the controller does not have |

| sufficient power or has failed. |

Unit wiring | The wiring between the controller outputs and the electric heat contacts must be present and correct for normal electric |

| heat operation. Refer to the unit wiring diagrams on the unit. |

| |

Table 47. Fresh air damper stays closed | |

|

|

Probable cause | Explanation |

|

|

| The controller includes both a warmup and cooldown sequence to keep the fresh air damper closed during the transition |

| from unoccupied to occupied. This is an attempt to bring the space under control as quickly as possible. |

Requested mode: off | It is possible to communicate the operating mode (such as off, heat, cool) to the controller. When off is communicated |

| to the controller, the unit closes the fresh air damper. |

Manual output test | The controller includes a manual output test sequence that verifies analog and binary output operation and associated |

| output wiring. However, based on the current step in the test sequence, the fresh air damper may not be open. Refer |

| to the “Manual Output Test,” p. 73. |

Diagnostic present | A specific list of diagnostics effects fresh air damper operation. For more information, see Table 41, p. 77 and Table 42, |

| p. 77. |

Unit configuration | The controller must be properly configured based on the actual installed end devices and application. When the unit |

| configuration does not match the actual end device, the damper may not work correctly. |

No power to the | If the controller does not have power, the unit fan does not operate. For the Tracer™ ZN010, 510 controller to operate |

controller | normally, it must have an input voltage of 24 VAC. When the green LED is off continuously, the controller does not have |

| sufficient power or has failed. |

Unit wiring | The wiring between the controller outputs and the fresh air damper must be present and correct for normal damper |

| operation. Refer to the unit wiring diagrams on the unit. |

|

|

| 79 |