Models FC & FF ZO and later design sequence

Installation, Operation, and Maintenance

Common Hvac Acronyms

General information

Contents

Model Number

General

Model Number Description

General

Digit 31 control option

Digit 28 auxiliary control valve 0 = none

Digit 29 piping packages 0 = none

Digit 30 control type 0 = none

Table I-GI-2. Low vertical fan-coil component data

Table I-GI-1. Fan-coil component data

Model M inverted vertical cabinet

Available Models

Model E horizontal recessed

Model K low vertical cabinet

Factory-Installed Piping Packages

Vertical Concealed, Model a

Dimensions

Installation Weights

Vertical Concealed Unit Dimensions & weights, in-lbs

Vertical Cabinet, Model B

Vertical Cabinet Unit Dimensions, in-lbs

Horizontal Concealed, Model C

Horizontal Concealed Unit Dimensions, in-lbs

Horizontal Cabinet, Model D

Horizontal Cabinet Unit Dimensions, in-lbs

Horizontal Recessed, Model E

Installation Dimensions Weights

Horizontal Recessed Unit Dimensions, in-lbs

Vertical Wall Hung Cabinet, Model F

Vertical wall hung cabinet unit dimensions & weights, in-lbs

Vertical Recessed, Model H

Vertical Recessed Unit Dimensions, in-lbs

Vertical Slope Top, Model J

Vertical Slope Top Unit Dimensions, in-lbs

Low Vertical Concealed, Model K

Low Vertical Concealed Unit Dimensions, in-lbs

Low Vertical Cabinet, Model L

Low Vertical Cabinet Unit Dimensions, in-lbs

Inverted Vertical Cabinet, Model M

Inverted vertical cabinet unit dimensions & weights, in-lbs

Inverted Vertical Recessed, Model N

Inverted vertical recessed unit dimensions & weights, in-lbs

Fan-Coil Coil Connections Vertical Units Horizontal Units

Horizontal Units Inverted Units

Force Flo Coil Connections Vertical Units

Fresh Air Opening Dimensions, Horizontal Units

Fresh Air Opening Dimensions, Vertical Units

Wall Box

Wall Box Dimensions

Projection Panel

Projection Panel Dimensions

Jobsite Storage

Pre-installation Installation considerations

Installation Preparation

Receiving and Handling

Pre-Installation Checklist

Service Access

Piping Considerations

Connecting field piping to coil

Mechanical

Duct Connections

Condensate Drain

Figure I-MR-4. Close-up view of the changeover sensor

Venting the Hydronic Coil

Figure I-MR-8. Manual circuit setter valve

Balancing The Manual Circuit Setter Valve

Mechanical

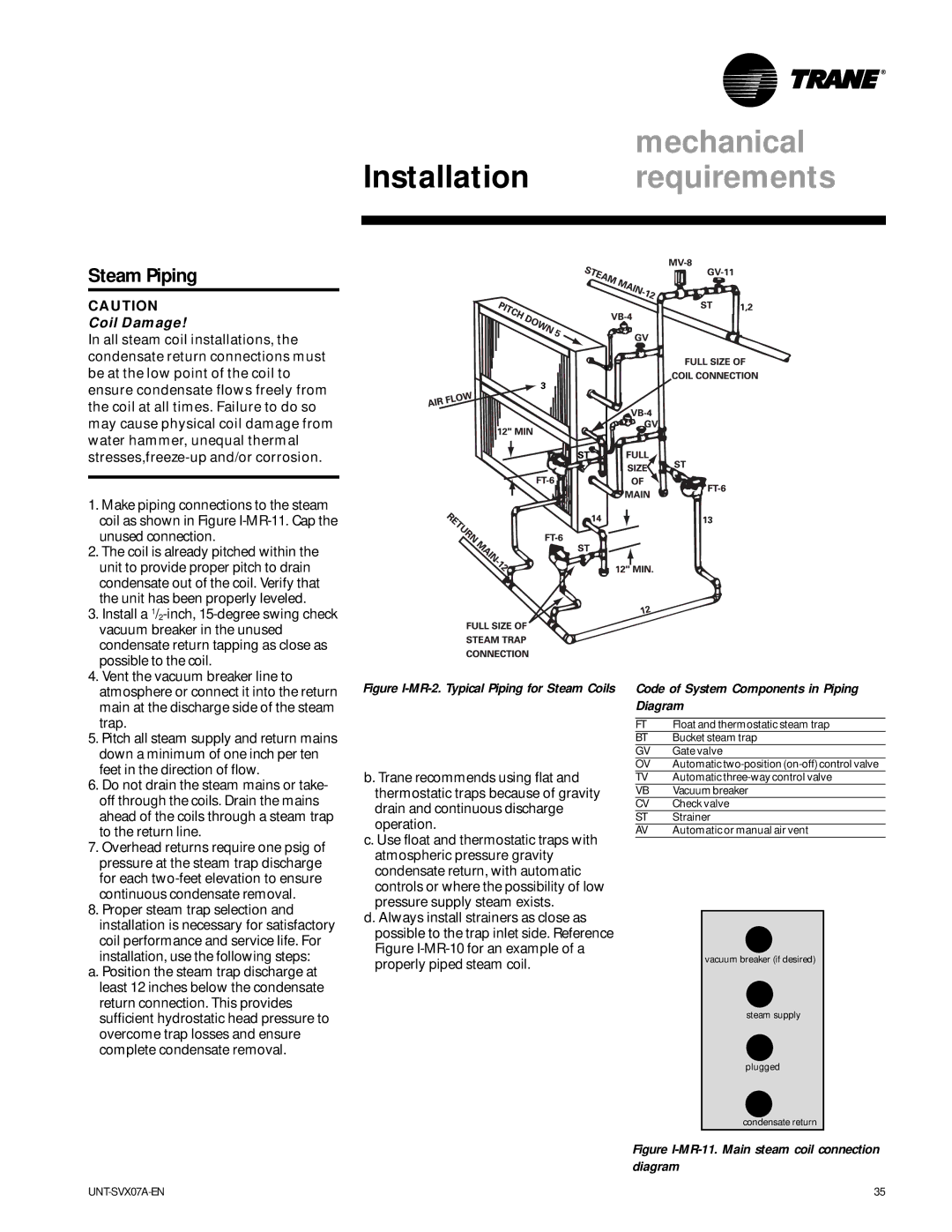

Steam Piping

Code of System Components in Piping Diagram

Electrical

Unit Wiring Diagrams

Supply Power Wiring

Wall Mounted Control Interconnection Wiring

Table I-ER-3. Decimal to fractional HP kW conversion

Table I-ER-2. Low vertical free discharge motors, 115 volt

Table I-ER-9. Electric heat kW

Table I-ER-8. Fan-coil electric heat kW

Table I-ER-11. Force Flo single stage, low kW electric heat

Table I-ER-10. Force Flo single-stage, max kW electric heat

Table I-ER-12. Force Flo 2-stage electric heat

Installing the Unit

Installation

Unit Leveling

Figure I-IP-5. Zone sensor only

Figure I-IP-3. Zone sensor with on/cancel Comm jack

Zone Sensor Installation

Installing Wall Mounted Controls

Wiring Instructions

Fan Mode Switch Installation

Unit Leveling

Installation Checklist

Device Addressing

Communication Wiring

Recommended Communication Wiring Practices

Pre-startup

Pre-Startup Checklist

Tracer ZN510 & ZN520 Unit Startup

Installation startup

Relay Board

Manual Fan Mode Switch

General Operation information

General Information

Tracer ZN520 Operation

Fan Mode Switch Operation

Sequence

Tracer ZN010 & ZN510 Operation

Binary Outputs

Binary Inputs

Supply Fan Operation

Fan Mode Switch

Analog Inputs

Zone Sensors

Tracer ZN520 Sequence of Operation

Discharge Air Tempering

Cooling Operation

Heating Operation

Continuous Fan Operation

Fan Mode Operation

Economizer Damper Option

Fan Start on High Speed

Electric Heat Operation

Manual Fresh Air Damper

Binary Outputs

Table O-SO-12. Binary input configurations

Table O-SO-13. Binary output configuration

Data Sharing

Table O-SO-15. Analog inputs

Table O-SO-14. Analog inputs

Zone Sensor

Fan Switch

On/Cancel Buttons

Table O-SO-16. Zone sensor wiring connections

Table M-D-1. Tracer ZN520 Diagnostics

Maintenance diagnostics

Cycling the Fan Switch

Translating Multiple Diagnostics

Resetting Diagnostics

Diagnostic Reset

Table M-D-5. Valves Stay Open

Table M-D-3. Fan outputs do not energize

Table M-D-4. Valves Stay Closed

Table M-D-8. Fresh Air Damper Stays Closed

Table M-D-6. Electric Heat Not Operating

Table M-D-7. Fresh Air Damper Stays Open

Switch SW2 Electric Heat

Maintenance troubleshooting

Troubleshooting the Relay Board

Switch SW1 Controller Type

Yellow Comm LED

Troubleshooting Tracer ZN010, ZN510 & ZN520

Red Service LED

Green Status LED

BOP5 BOP6

Table M-T-1. Test sequence for 1-heat/1-cool configurations

Main Drain Pan

Maintenance

Maintenance Procedures

Winterizing the Coil

Coil Maintenance

Steam and Hydronic Coil Cleaning Procedure

Replacing the Motor

Control Device Replacement

Annual Maintenance

Periodic Maintenance Checklists

Monthly Checklist

Monthly Maintenance

Csti Fan Speed Switch

Typical wiring

Csti Non Fan Speed Switch

Line voltage fan speed switch

Tracer ZN010 with electric heat

Tracer ZN510 with main and auxilliary valves

ZN520 with 2-stage electric heat

Page

Page

Page

PL-TD-UNT-SVX07A-EN