maintenance

Maintenance procedures

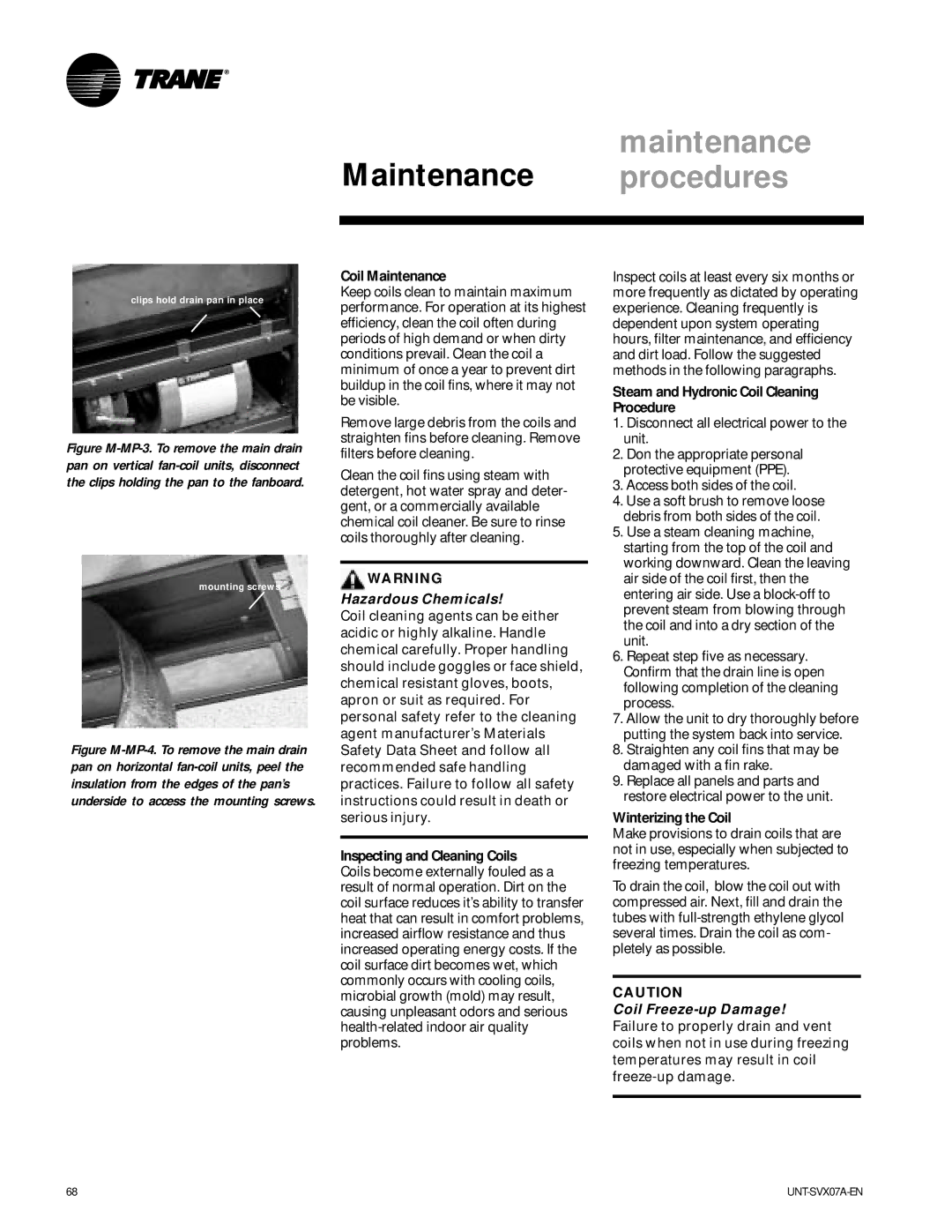

clips hold drain pan in place

Figure M-MP-3. To remove the main drain pan on vertical fan-coil units, disconnect the clips holding the pan to the fanboard.

Coil Maintenance

Keep coils clean to maintain maximum performance. For operation at its highest efficiency, clean the coil often during periods of high demand or when dirty conditions prevail. Clean the coil a minimum of once a year to prevent dirt buildup in the coil fins, where it may not be visible.

Remove large debris from the coils and straighten fins before cleaning. Remove filters before cleaning.

Clean the coil fins using steam with detergent, hot water spray and deter- gent, or a commercially available chemical coil cleaner. Be sure to rinse coils thoroughly after cleaning.

Inspect coils at least every six months or more frequently as dictated by operating experience. Cleaning frequently is dependent upon system operating hours, filter maintenance, and efficiency and dirt load. Follow the suggested methods in the following paragraphs.

Steam and Hydronic Coil Cleaning Procedure

1. Disconnect all electrical power to the |

unit. |

2. Don the appropriate personal |

protective equipment (PPE). |

3. Access both sides of the coil. |

4. Use a soft brush to remove loose |

debris from both sides of the coil. |

5. Use a steam cleaning machine, |

starting from the top of the coil and |

working downward. Clean the leaving |

mounting screws

Figure M-MP-4. To remove the main drain pan on horizontal fan-coil units, peel the insulation from the edges of the pan’s underside to access the mounting screws.

![]() WARNING

WARNING

Hazardous Chemicals!

Coil cleaning agents can be either acidic or highly alkaline. Handle chemical carefully. Proper handling should include goggles or face shield, chemical resistant gloves, boots, apron or suit as required. For personal safety refer to the cleaning agent manufacturer’s Materials Safety Data Sheet and follow all recommended safe handling practices. Failure to follow all safety instructions could result in death or serious injury.

Inspecting and Cleaning Coils Coils become externally fouled as a result of normal operation. Dirt on the coil surface reduces it’s ability to transfer heat that can result in comfort problems, increased airflow resistance and thus increased operating energy costs. If the coil surface dirt becomes wet, which commonly occurs with cooling coils, microbial growth (mold) may result, causing unpleasant odors and serious

air side of the coil first, then the |

entering air side. Use a |

prevent steam from blowing through |

the coil and into a dry section of the |

unit. |

6. Repeat step five as necessary. |

Confirm that the drain line is open |

following completion of the cleaning |

process. |

7. Allow the unit to dry thoroughly before |

putting the system back into service. |

8. Straighten any coil fins that may be |

damaged with a fin rake. |

9. Replace all panels and parts and |

restore electrical power to the unit. |

Winterizing the Coil

Make provisions to drain coils that are not in use, especially when subjected to freezing temperatures.

To drain the coil, blow the coil out with compressed air. Next, fill and drain the tubes with

CAUTION

Coil

68 |