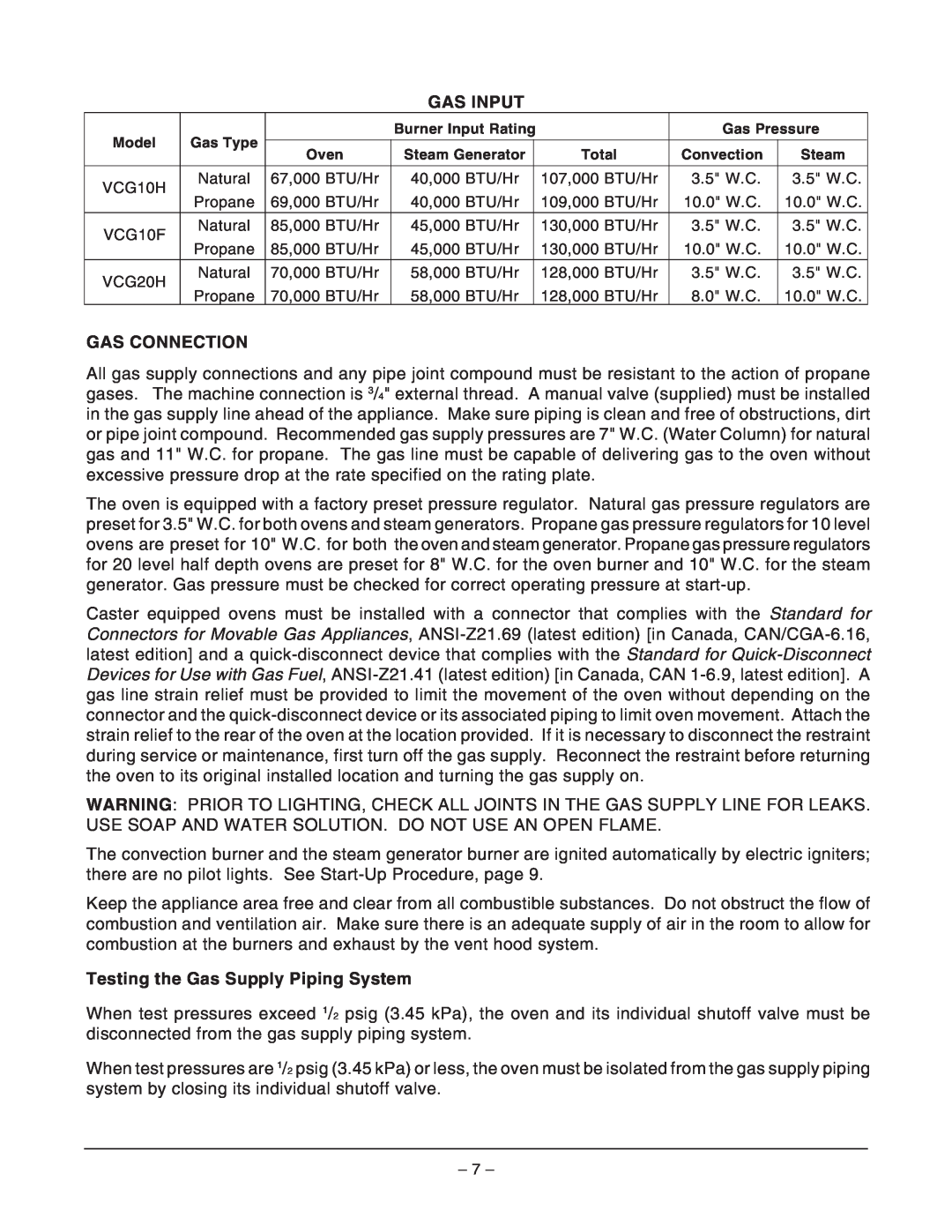

GAS INPUT

Model | Gas Type |

| Burner Input Rating |

| Gas Pressure | ||

|

|

|

|

|

| ||

Oven | Steam Generator |

| Total | Convection | Steam | ||

|

|

| |||||

|

|

|

|

|

|

|

|

VCG10H | Natural | 67,000 BTU/Hr | 40,000 BTU/Hr |

| 107,000 BTU/Hr | 3.5" W.C. | 3.5" W.C. |

Propane | 69,000 BTU/Hr | 40,000 BTU/Hr |

| 109,000 BTU/Hr | 10.0" W.C. | 10.0" W.C. | |

|

| ||||||

|

|

|

|

|

|

|

|

VCG10F | Natural | 85,000 BTU/Hr | 45,000 BTU/Hr |

| 130,000 BTU/Hr | 3.5" W.C. | 3.5" W.C. |

Propane | 85,000 BTU/Hr | 45,000 BTU/Hr |

| 130,000 BTU/Hr | 10.0" W.C. | 10.0" W.C. | |

|

| ||||||

VCG20H | Natural | 70,000 BTU/Hr | 58,000 BTU/Hr |

| 128,000 BTU/Hr | 3.5" W.C. | 3.5" W.C. |

Propane | 70,000 BTU/Hr | 58,000 BTU/Hr |

| 128,000 BTU/Hr | 8.0" W.C. | 10.0" W.C. | |

|

| ||||||

GAS CONNECTION

All gas supply connections and any pipe joint compound must be resistant to the action of propane gases. The machine connection is 3/4" external thread. A manual valve (supplied) must be installed in the gas supply line ahead of the appliance. Make sure piping is clean and free of obstructions, dirt or pipe joint compound. Recommended gas supply pressures are 7" W.C. (Water Column) for natural gas and 11" W.C. for propane. The gas line must be capable of delivering gas to the oven without excessive pressure drop at the rate specified on the rating plate.

The oven is equipped with a factory preset pressure regulator. Natural gas pressure regulators are preset for 3.5" W.C. for both ovens and steam generators. Propane gas pressure regulators for 10 level ovens are preset for 10" W.C. for both the oven and steam generator. Propane gas pressure regulators for 20 level half depth ovens are preset for 8" W.C. for the oven burner and 10" W.C. for the steam generator. Gas pressure must be checked for correct operating pressure at

Caster equipped ovens must be installed with a connector that complies with the Standard for Connectors for Movable Gas Appliances,

WARNING: PRIOR TO LIGHTING, CHECK ALL JOINTS IN THE GAS SUPPLY LINE FOR LEAKS. USE SOAP AND WATER SOLUTION. DO NOT USE AN OPEN FLAME.

The convection burner and the steam generator burner are ignited automatically by electric igniters; there are no pilot lights. See

Keep the appliance area free and clear from all combustible substances. Do not obstruct the flow of combustion and ventilation air. Make sure there is an adequate supply of air in the room to allow for combustion at the burners and exhaust by the vent hood system.

Testing the Gas Supply Piping System

When test pressures exceed 1/2 psig (3.45 kPa), the oven and its individual shutoff valve must be disconnected from the gas supply piping system.

When test pressures are 1/2 psig (3.45 kPa) or less, the oven must be isolated from the gas supply piping system by closing its individual shutoff valve.

– 7 –