FULL SIZE GAS CONVECTION OVENS - SERVICE PROCEDURES AND ADJUSTMENTS

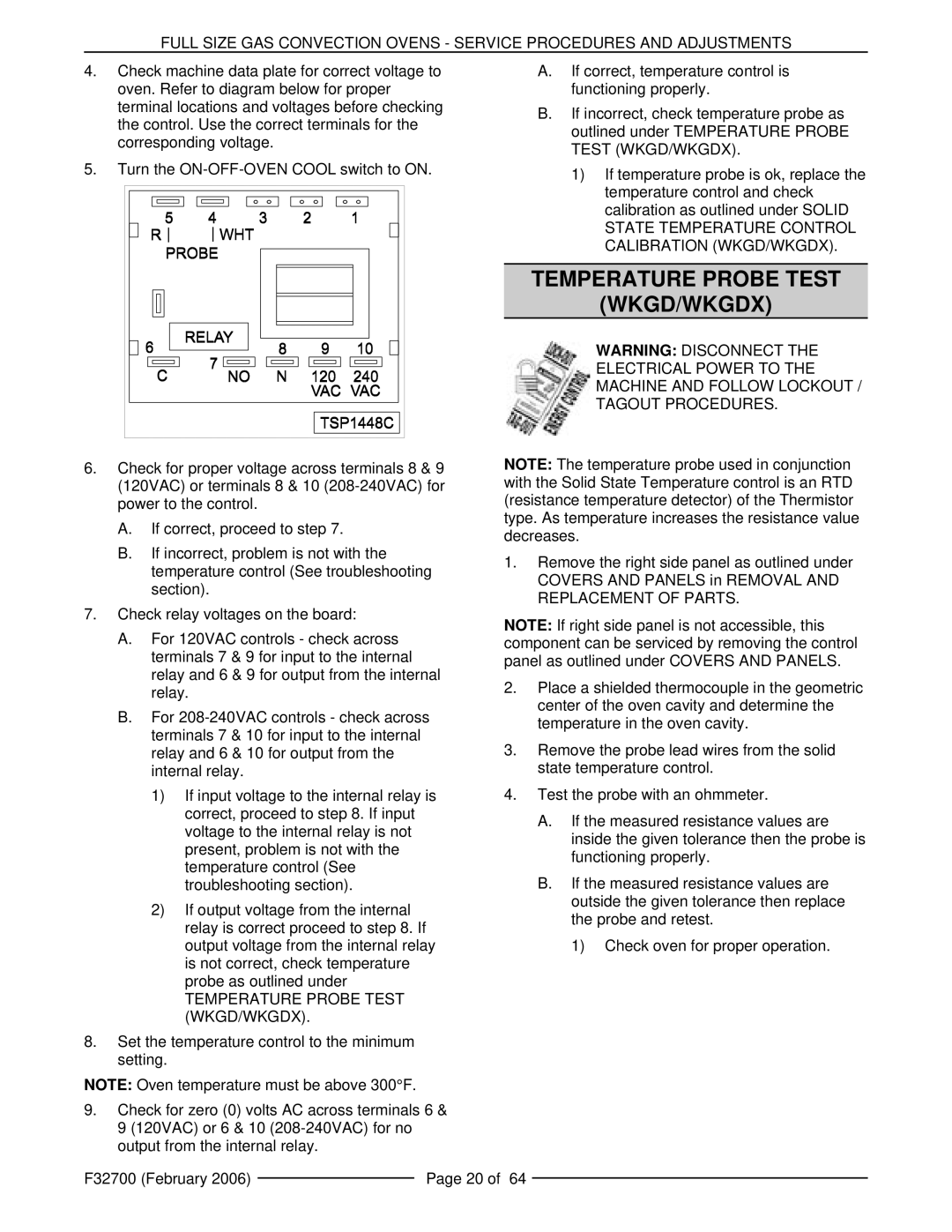

4.Check machine data plate for correct voltage to oven. Refer to diagram below for proper terminal locations and voltages before checking the control. Use the correct terminals for the corresponding voltage.

5.Turn the

6.Check for proper voltage across terminals 8 & 9 (120VAC) or terminals 8 & 10

A.If correct, proceed to step 7.

B.If incorrect, problem is not with the temperature control (See troubleshooting section).

7.Check relay voltages on the board:

A.For 120VAC controls - check across terminals 7 & 9 for input to the internal relay and 6 & 9 for output from the internal relay.

B.For

1)If input voltage to the internal relay is correct, proceed to step 8. If input voltage to the internal relay is not present, problem is not with the temperature control (See troubleshooting section).

2)If output voltage from the internal relay is correct proceed to step 8. If output voltage from the internal relay is not correct, check temperature probe as outlined under

TEMPERATURE PROBE TEST (WKGD/WKGDX).

8.Set the temperature control to the minimum setting.

NOTE: Oven temperature must be above 300°F.

9.Check for zero (0) volts AC across terminals 6 & 9 (120VAC) or 6 & 10

A.If correct, temperature control is functioning properly.

B.If incorrect, check temperature probe as outlined under TEMPERATURE PROBE TEST (WKGD/WKGDX).

1)If temperature probe is ok, replace the temperature control and check calibration as outlined under SOLID STATE TEMPERATURE CONTROL CALIBRATION (WKGD/WKGDX).

TEMPERATURE PROBE TEST

(WKGD/WKGDX)

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

NOTE: The temperature probe used in conjunction with the Solid State Temperature control is an RTD (resistance temperature detector) of the Thermistor type. As temperature increases the resistance value decreases.

1.Remove the right side panel as outlined under COVERS AND PANELS in REMOVAL AND REPLACEMENT OF PARTS.

NOTE: If right side panel is not accessible, this component can be serviced by removing the control panel as outlined under COVERS AND PANELS.

2.Place a shielded thermocouple in the geometric center of the oven cavity and determine the temperature in the oven cavity.

3.Remove the probe lead wires from the solid state temperature control.

4.Test the probe with an ohmmeter.

A.If the measured resistance values are inside the given tolerance then the probe is functioning properly.

B.If the measured resistance values are outside the given tolerance then replace the probe and retest.

1)Check oven for proper operation.

F32700 (February 2006) |

| Page 20 of 64 |

|