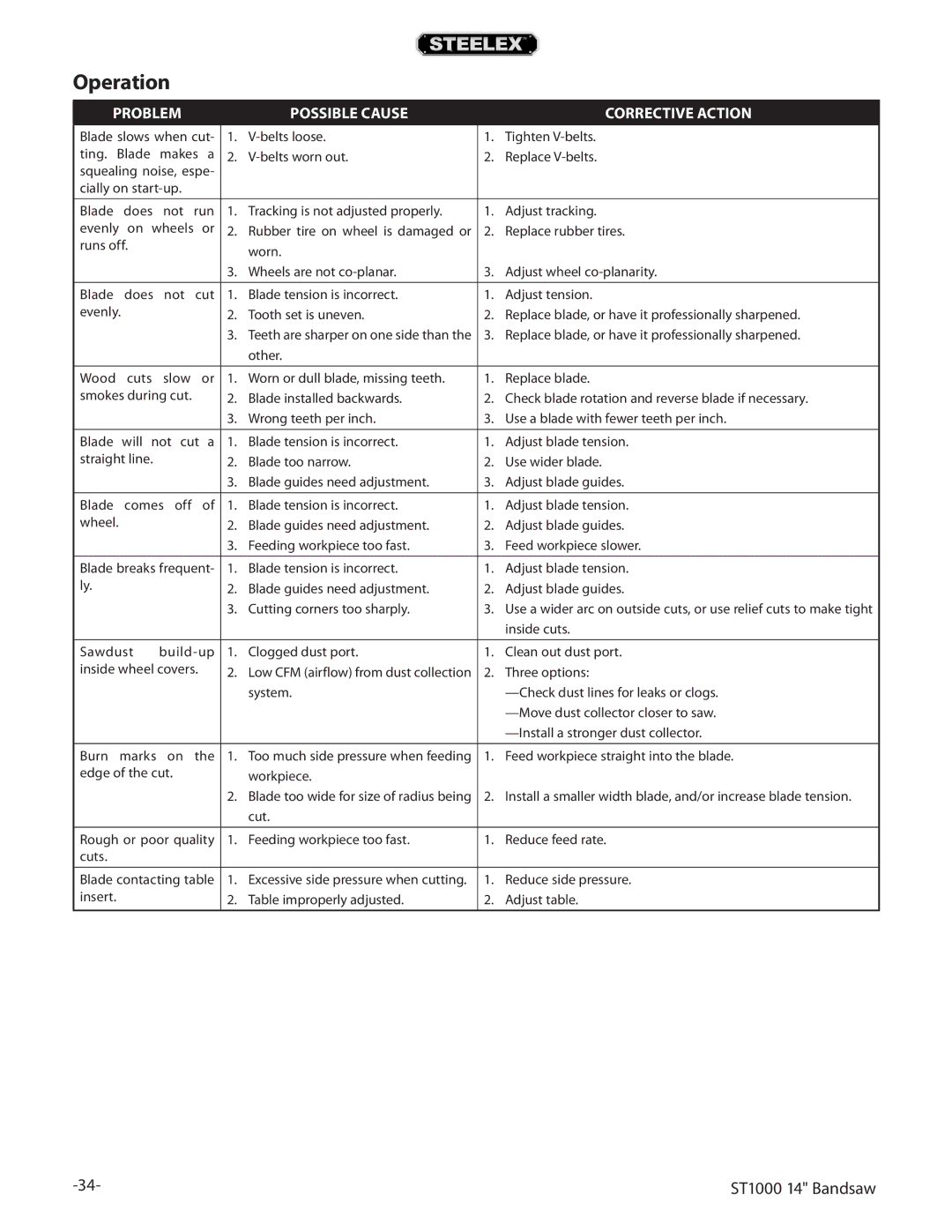

Operation

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Blade slows when cut- | 1. | 1. | Tighten | ||||

ting. Blade | makes a | 2. | 2. | Replace | |||

squealing noise, espe- |

|

|

|

| |||

cially on |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

Blade | does | not | run | 1. | Tracking is not adjusted properly. | 1. | Adjust tracking. |

evenly | on wheels | or | 2. | Rubber tire on wheel is damaged or | 2. | Replace rubber tires. | |

runs off. |

|

|

| worn. |

|

| |

|

|

|

|

|

|

| |

|

|

|

| 3. | Wheels are not | 3. | Adjust wheel |

|

|

|

|

| |||

Blade does not cut | 1. | Blade tension is incorrect. | 1. | Adjust tension. | |||

evenly. |

|

|

| 2. | Tooth set is uneven. | 2. | Replace blade, or have it professionally sharpened. |

|

|

|

| 3. | Teeth are sharper on one side than the | 3. | Replace blade, or have it professionally sharpened. |

|

|

|

|

| other. |

|

|

|

|

|

|

| |||

Wood cuts slow or | 1. | Worn or dull blade, missing teeth. | 1. | Replace blade. | |||

smokes during cut. |

| 2. | Blade installed backwards. | 2. | Check blade rotation and reverse blade if necessary. | ||

|

|

|

| 3. | Wrong teeth per inch. | 3. | Use a blade with fewer teeth per inch. |

|

|

|

|

| |||

Blade will not cut a | 1. | Blade tension is incorrect. | 1. | Adjust blade tension. | |||

straight line. |

|

| 2. | Blade too narrow. | 2. | Use wider blade. | |

|

|

|

| 3. | Blade guides need adjustment. | 3. | Adjust blade guides. |

|

|

|

|

| |||

Blade comes off of | 1. | Blade tension is incorrect. | 1. | Adjust blade tension. | |||

wheel. |

|

|

| 2. | Blade guides need adjustment. | 2. | Adjust blade guides. |

|

|

|

| 3. | Feeding workpiece too fast. | 3. | Feed workpiece slower. |

|

|

|

|

| |||

Blade breaks frequent- | 1. | Blade tension is incorrect. | 1. | Adjust blade tension. | |||

ly. |

|

|

| 2. | Blade guides need adjustment. | 2. | Adjust blade guides. |

|

|

|

| 3. | Cutting corners too sharply. | 3. | Use a wider arc on outside cuts, or use relief cuts to make tight |

|

|

|

|

|

|

| inside cuts. |

|

|

|

|

|

| ||

Sawdust | 1. | Clogged dust port. | 1. | Clean out dust port. | |||

inside wheel covers. | 2. | Low CFM (airflow) from dust collection | 2. | Three options: | |||

|

|

|

|

| system. |

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

| |||

Burn marks on the | 1. | Too much side pressure when feeding | 1. | Feed workpiece straight into the blade. | |||

edge of the cut. |

|

| workpiece. |

|

| ||

|

|

|

| 2. | Blade too wide for size of radius being | 2. | Install a smaller width blade, and/or increase blade tension. |

|

|

|

|

| cut. |

|

|

|

|

|

|

| |||

Rough or poor quality | 1. | Feeding workpiece too fast. | 1. | Reduce feed rate. | |||

cuts. |

|

|

|

|

|

|

|

|

|

|

|

| |||

Blade contacting table | 1. | Excessive side pressure when cutting. | 1. | Reduce side pressure. | |||

insert. |

|

|

| 2. | Table improperly adjusted. | 2. | Adjust table. |

|

|

|

|

|

|

|

|

ST1000 14" Bandsaw |