Wheel Alignment

Wheel alignment is one of the easiest ways to ensure you get optimal performance from your bandsaw. When wheels are aligned, or coplanar, the bandsaw is more likely to cut straight without wandering; and vibration, heat, and blade wear are consider- ably decreased because the blade is automatically balanced on the wheel. This is known as “Coplanar Tracking.”

To verify if the upper and lower wheels are copla- nar:

1.UNPLUG THE BANDSAW!

2.Remove the table.

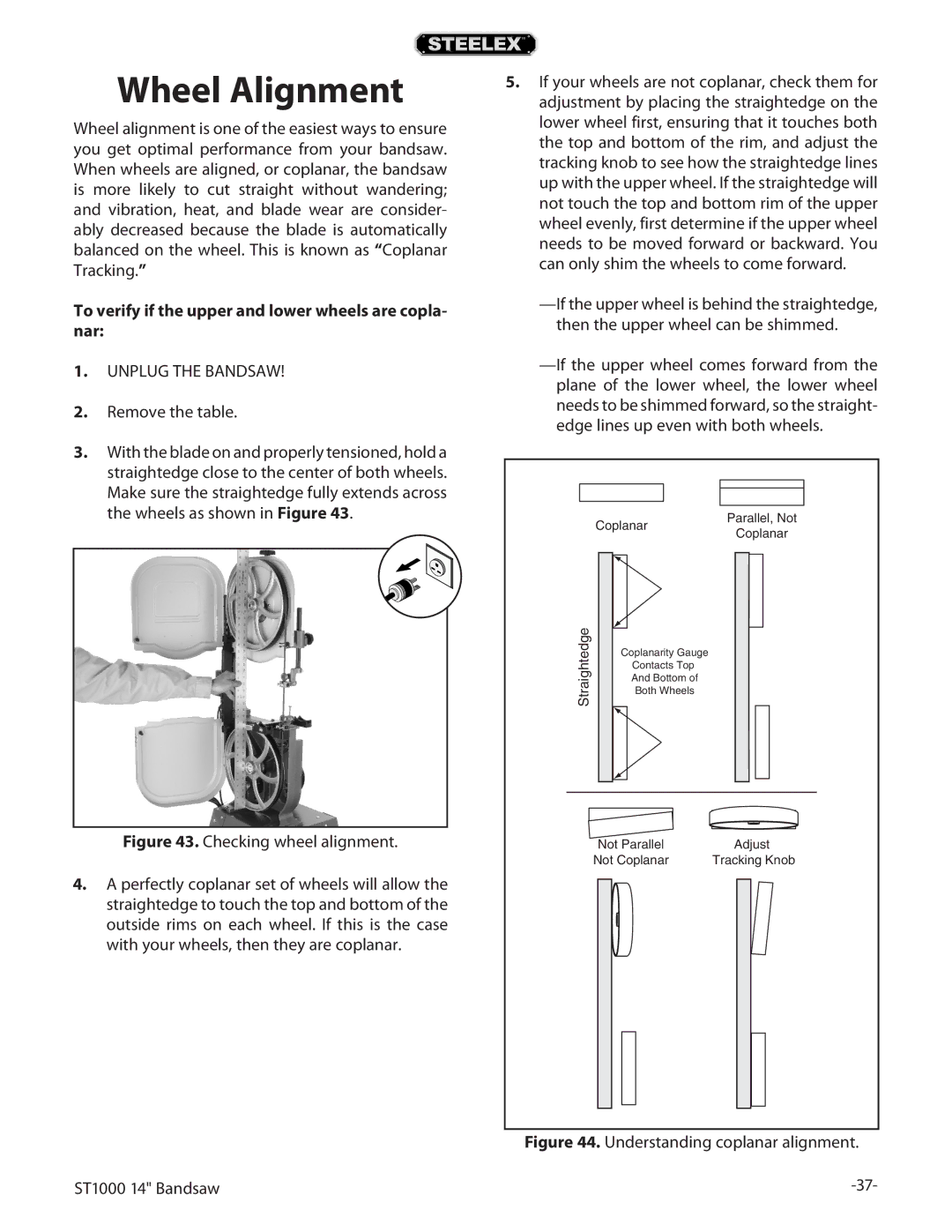

3.With the blade on and properly tensioned, hold a straightedge close to the center of both wheels. Make sure the straightedge fully extends across the wheels as shown in Figure 43.

Figure 43. Checking wheel alignment.

4.A perfectly coplanar set of wheels will allow the straightedge to touch the top and bottom of the outside rims on each wheel. If this is the case with your wheels, then they are coplanar.

ST1000 14" Bandsaw

5.If your wheels are not coplanar, check them for adjustment by placing the straightedge on the lower wheel first, ensuring that it touches both the top and bottom of the rim, and adjust the tracking knob to see how the straightedge lines up with the upper wheel. If the straightedge will not touch the top and bottom rim of the upper wheel evenly, first determine if the upper wheel needs to be moved forward or backward. You can only shim the wheels to come forward.

Coplanar | Parallel, Not | |

Coplanar | ||

|

Straightedge | Coplanarity Gauge |

|

|

| |

| Contacts Top |

|

| And Bottom of |

|

| Both Wheels |

|

| Not Parallel | Adjust |

| Not Coplanar | Tracking Knob |