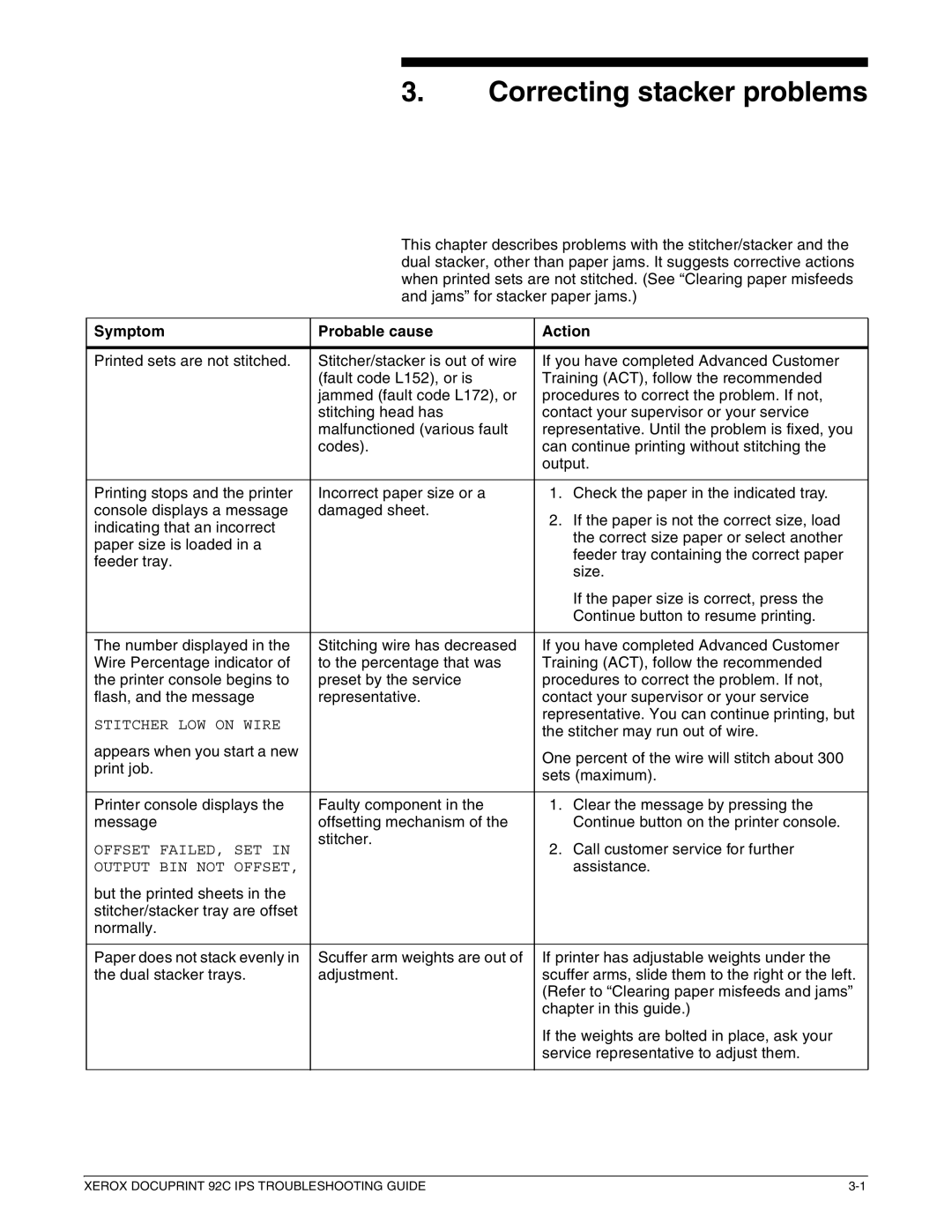

3.Correcting stacker problems

This chapter describes problems with the stitcher/stacker and the dual stacker, other than paper jams. It suggests corrective actions when printed sets are not stitched. (See “Clearing paper misfeeds and jams” for stacker paper jams.)

Symptom | Probable cause | Action |

|

|

|

Printed sets are not stitched. | Stitcher/stacker is out of wire | If you have completed Advanced Customer |

| (fault code L152), or is | Training (ACT), follow the recommended |

| jammed (fault code L172), or | procedures to correct the problem. If not, |

| stitching head has | contact your supervisor or your service |

| malfunctioned (various fault | representative. Until the problem is fixed, you |

| codes). | can continue printing without stitching the |

|

| output. |

|

|

|

Printing stops and the printer | Incorrect paper size or a | 1. Check the paper in the indicated tray. |

console displays a message | damaged sheet. | 2. If the paper is not the correct size, load |

indicating that an incorrect |

| |

| the correct size paper or select another | |

paper size is loaded in a |

| |

| feeder tray containing the correct paper | |

feeder tray. |

| |

| size. | |

|

| |

|

| If the paper size is correct, press the |

|

| Continue button to resume printing. |

|

|

|

The number displayed in the | Stitching wire has decreased | If you have completed Advanced Customer |

Wire Percentage indicator of | to the percentage that was | Training (ACT), follow the recommended |

the printer console begins to | preset by the service | procedures to correct the problem. If not, |

flash, and the message | representative. | contact your supervisor or your service |

STITCHER LOW ON WIRE |

| representative. You can continue printing, but |

| the stitcher may run out of wire. | |

|

| |

appears when you start a new |

| One percent of the wire will stitch about 300 |

print job. |

| |

| sets (maximum). | |

|

| |

|

|

|

Printer console displays the | Faulty component in the | 1. Clear the message by pressing the |

message | offsetting mechanism of the | Continue button on the printer console. |

OFFSET FAILED, SET IN | stitcher. | 2. Call customer service for further |

| ||

OUTPUT BIN NOT OFFSET, |

| assistance. |

but the printed sheets in the |

|

|

stitcher/stacker tray are offset |

|

|

normally. |

|

|

|

|

|

Paper does not stack evenly in | Scuffer arm weights are out of | If printer has adjustable weights under the |

the dual stacker trays. | adjustment. | scuffer arms, slide them to the right or the left. |

|

| (Refer to “Clearing paper misfeeds and jams” |

|

| chapter in this guide.) |

|

| If the weights are bolted in place, ask your |

|

| service representative to adjust them. |

|

|

|

XEROX DOCUPRINT 92C IPS TROUBLESHOOTING GUIDE |