Section 5: Maintenance

![]() WARNING

WARNING

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to a complete stop, disconnect spark plug wire and move wire away from spark plug. Remove ignition key, if so equipped.

Failure to follow these instructions can result in serious personal injury or property damage.

Adding Gear Oil to the

PTO Power Unit Transmission

1.Do steps 1 and 2 of Checking the Power Unit Oil Level on page 32.

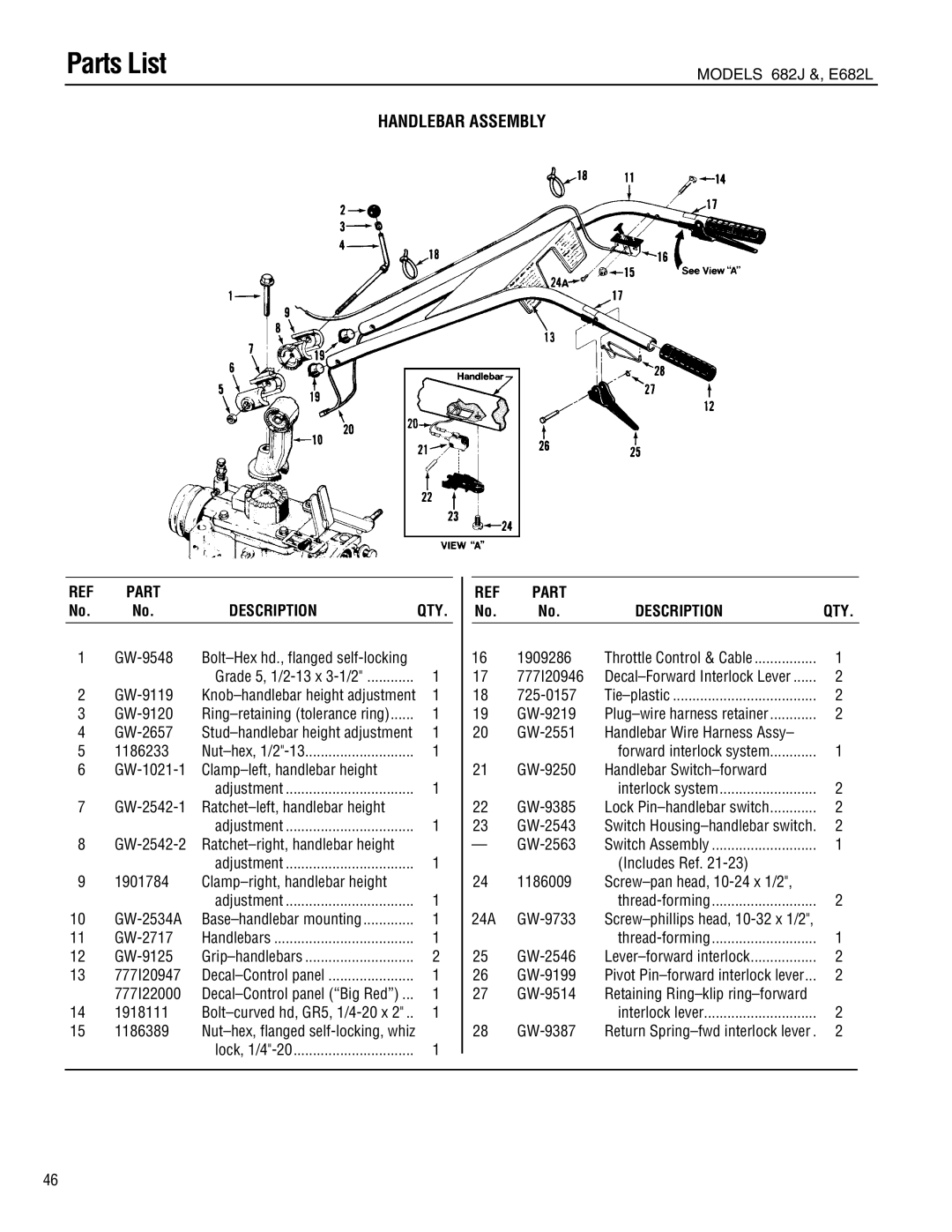

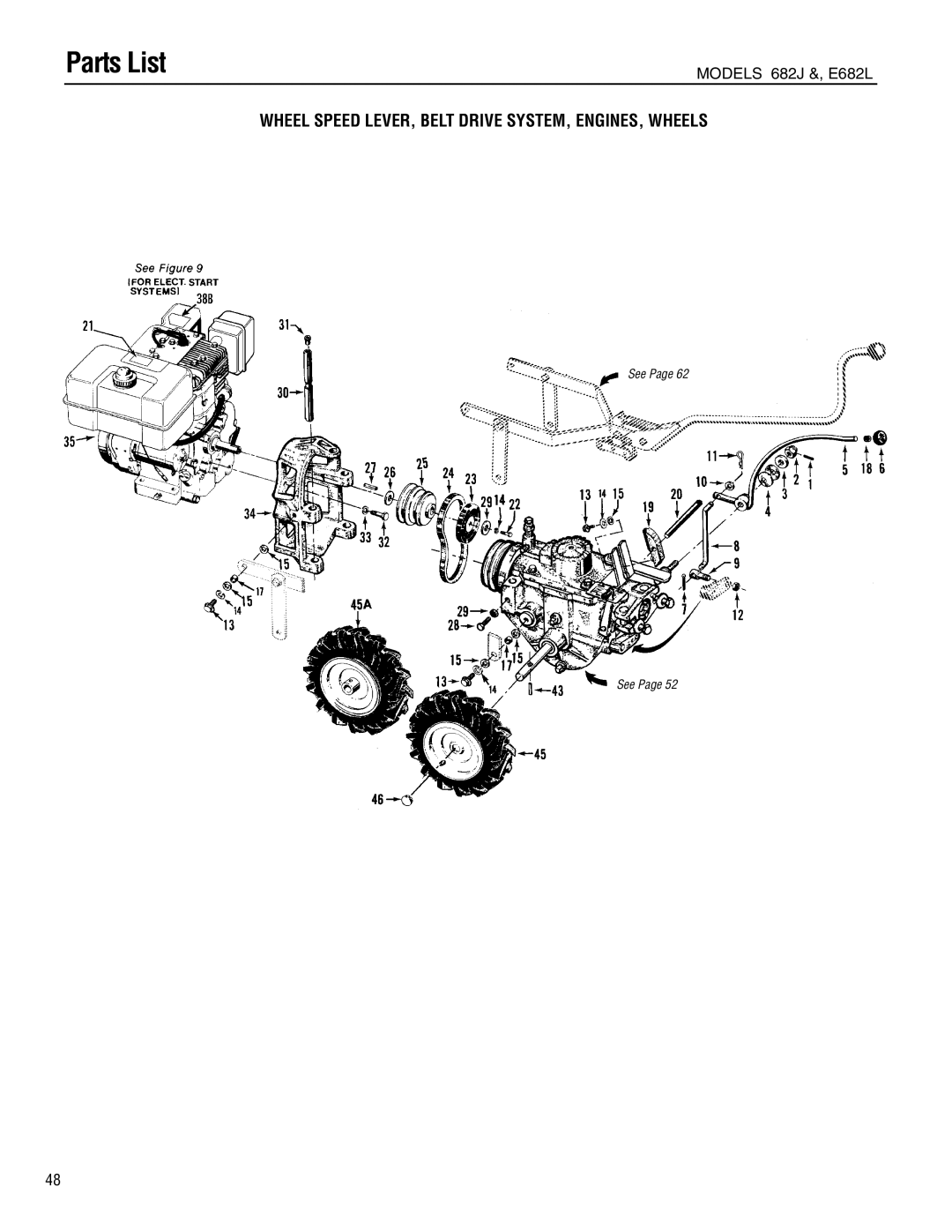

2.Using a 3/4" wrench (or socket), remove the bolt securing the handlebar base to the top of the transmission (prop the handlebars first to prevent them from falling).

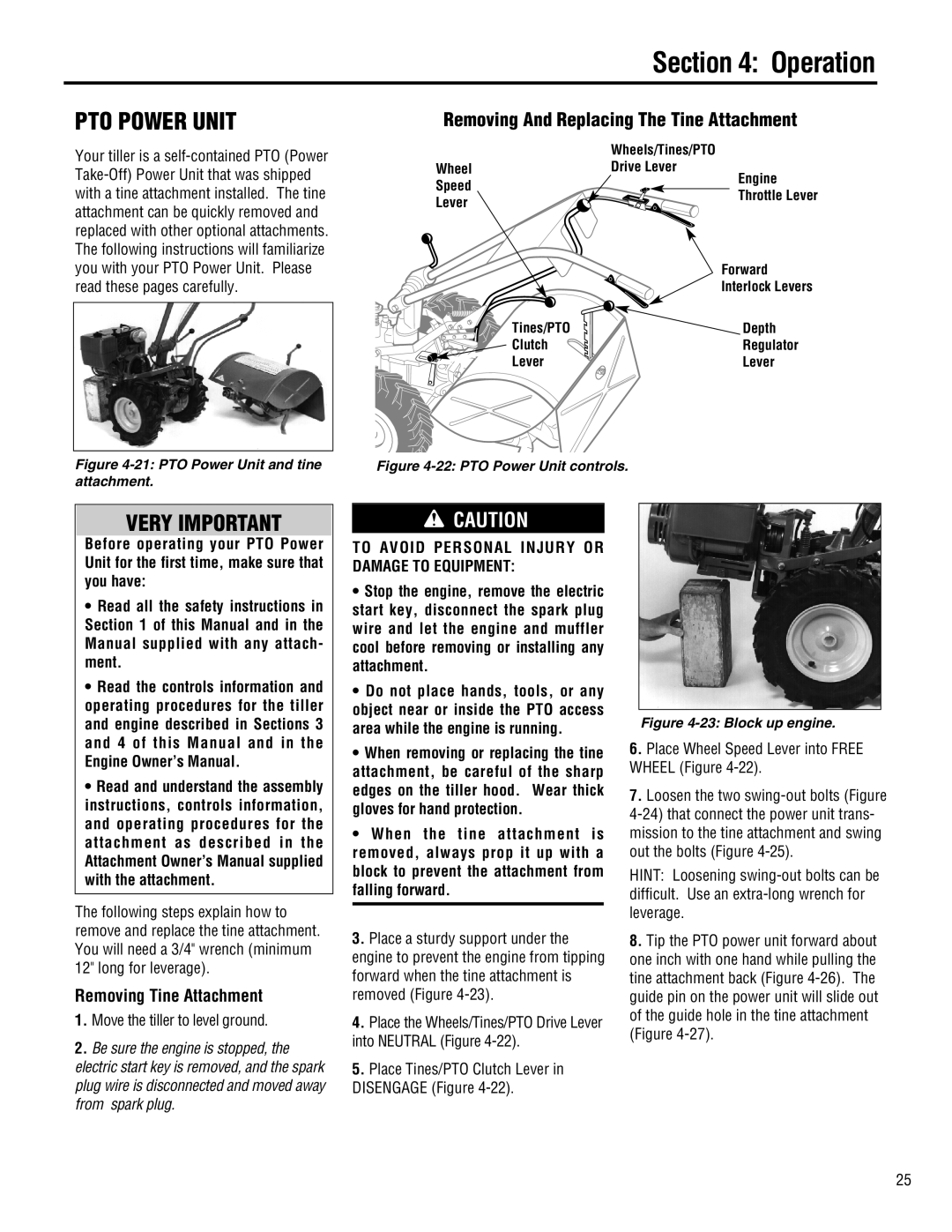

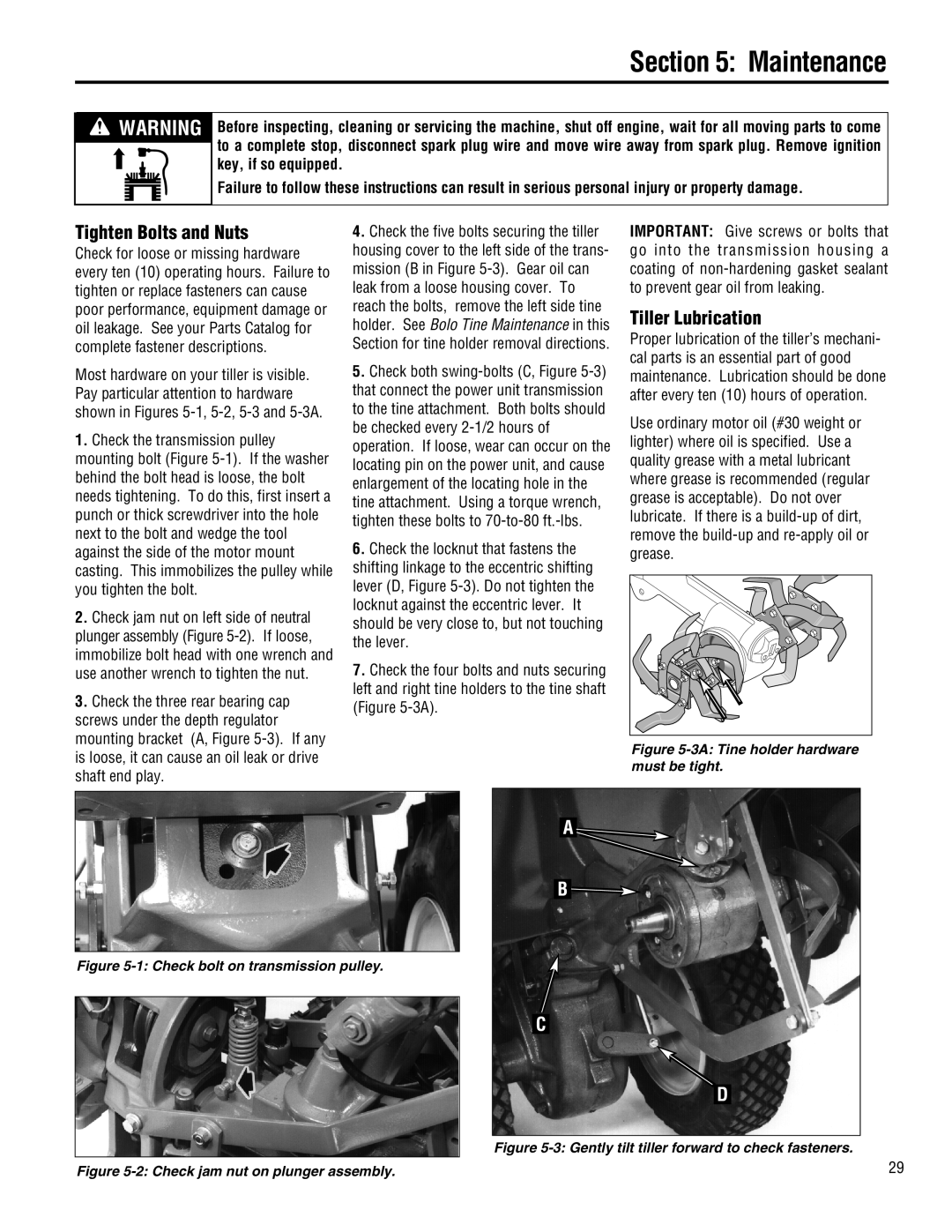

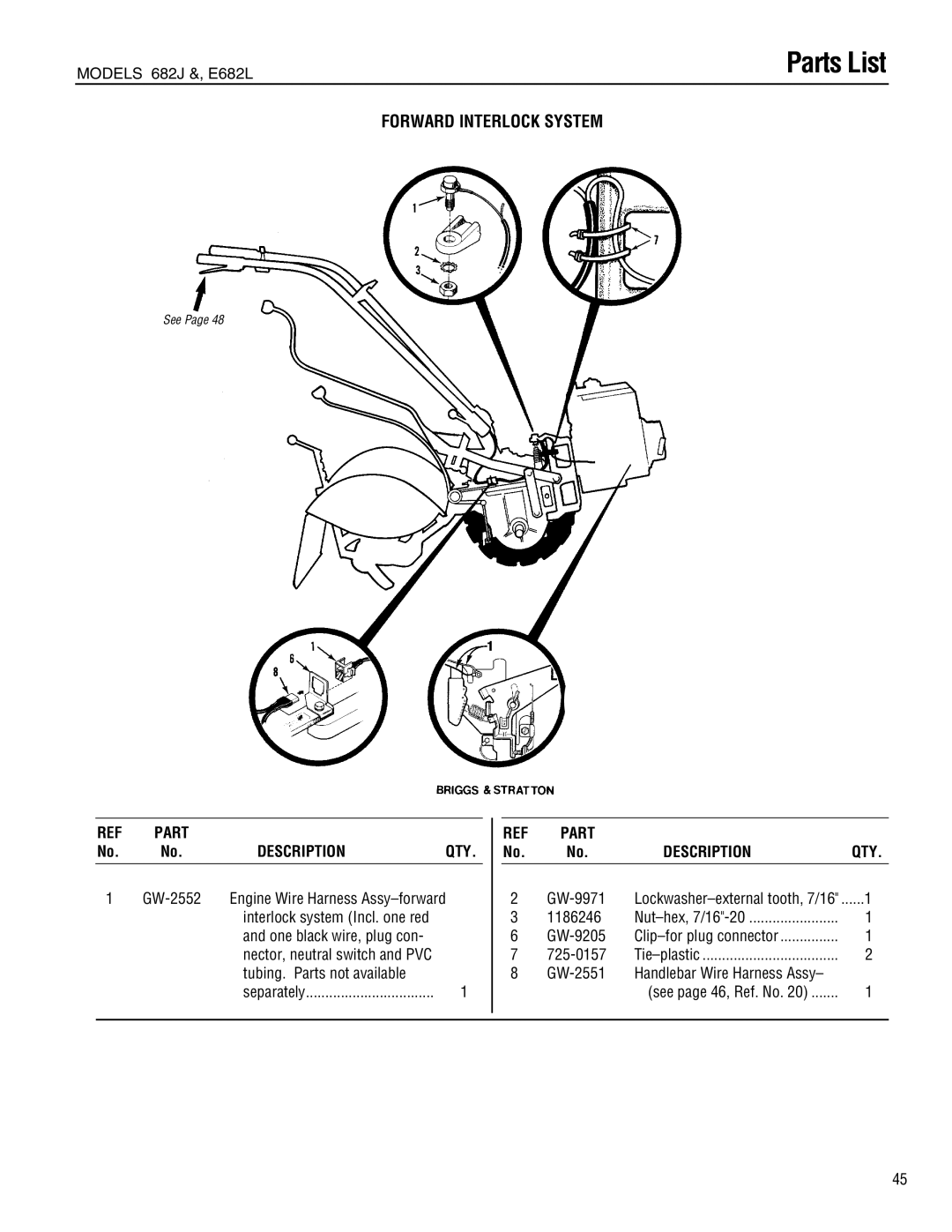

Then, unplug the Forward Interlock wire harness receptacle at the bottom of the handlebars. Set the handlebar base and bolt aside on a clean surface. The bolt hole in the top of the transmission is the gear oil fill hole (A, Figure

3.Slowly pour gear oil through a clean funnel into the transmission. Stop when gear oil begins to flow from the oil level check hole on the left side of the trans- mission (B, Figure

4.Reinstall the oil level check plug. Tighten it securely.

5.Reinstall the handlebars using the mounting bolt previously removed. Align the handlebars so they point straight backwards, not at an angle. Then tighten the mounting bolt securely.

6.Reconnect the Forward Interlock wire harness to the receptacle. Be certain it’s secure.

7.Test operation of the Forward Interlock Safety System. See Section 4 for a procedure.

Draining and Filling the

PTO Power Unit Transmission

1.Place a shallow pan under the trans- mission gear oil drain plug (B, Figure

2.Remove the oil level check plug (Figure

A |

B |

Figure

3.Using the 3/8" wrench, remove the drain plug (B, Figure

4.Clean the drain plug threads, put non- hardening gasket sealant on the threads, and reinstall plug.

5.Refill the transmission with the correct amount of gear oil before operating the tiller again. When oil seeps from the oil level check hole, the right amount of gear oil has been added. Replace all plugs.

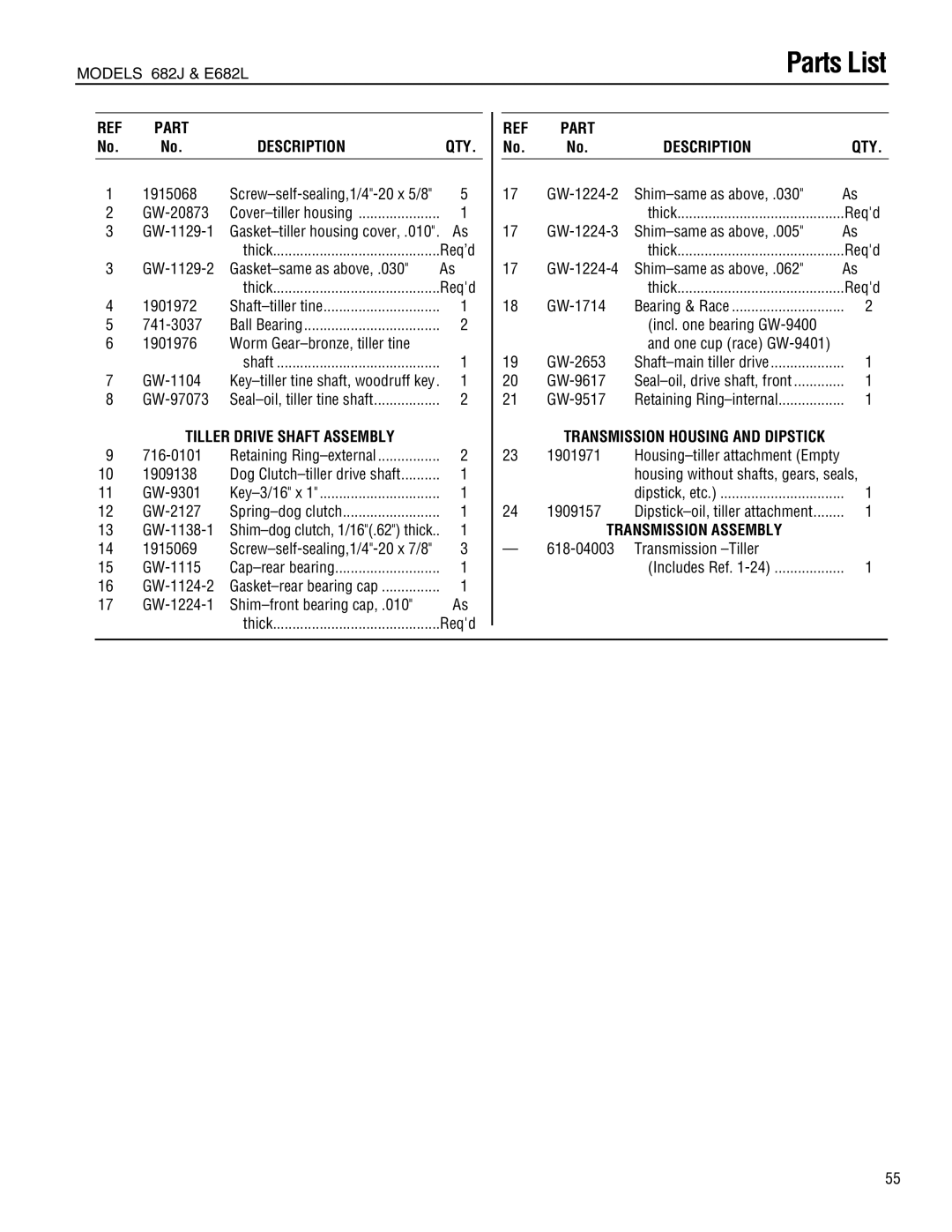

Adding Gear Oil to the Tine

Attachment Transmission

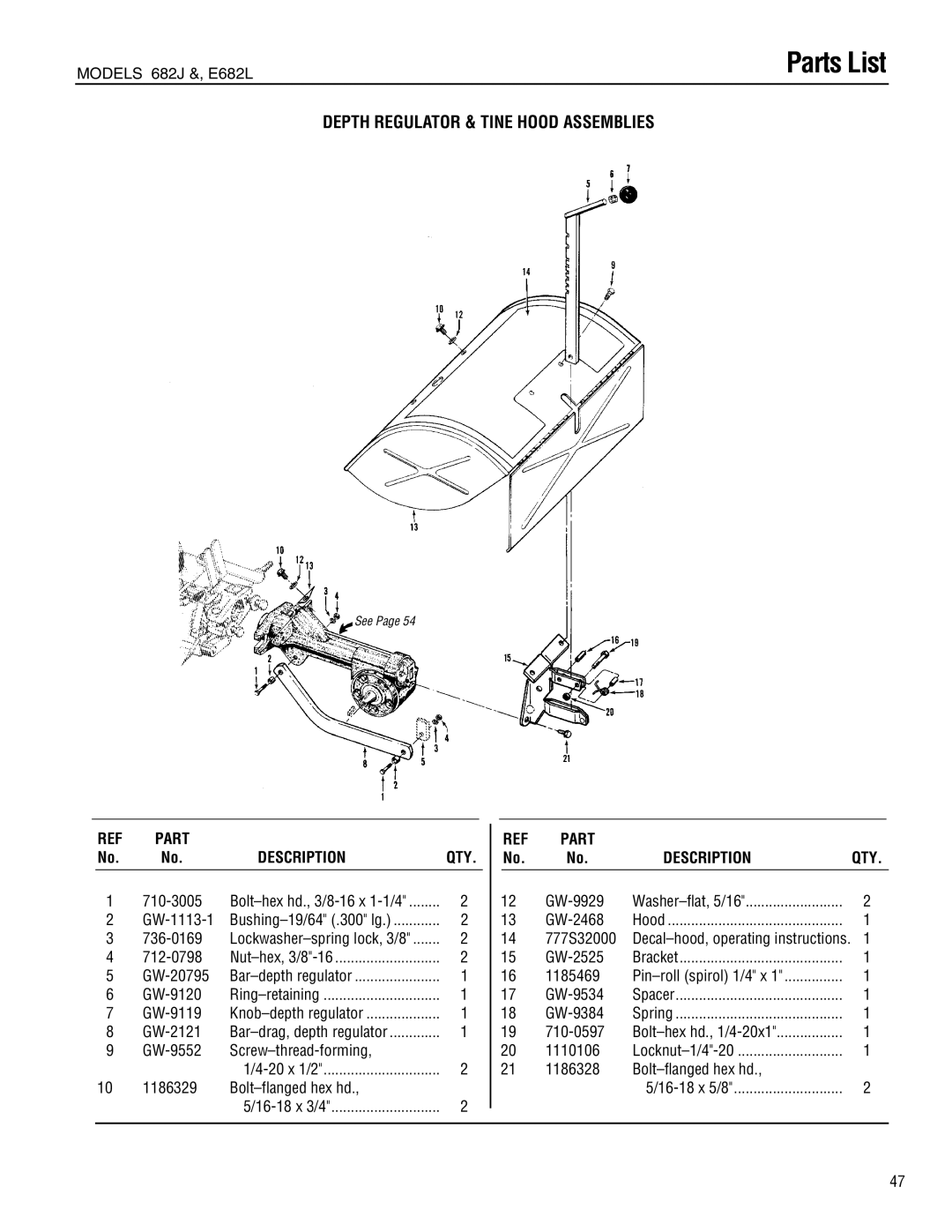

1.Select the right Depth Regulator Lever setting:

a.If filling an empty transmission, raise the Depth Regulator Lever so tines are on the ground.

b.If topping off the gear oil, move Depth Regulator Lever down to engage its top notch.

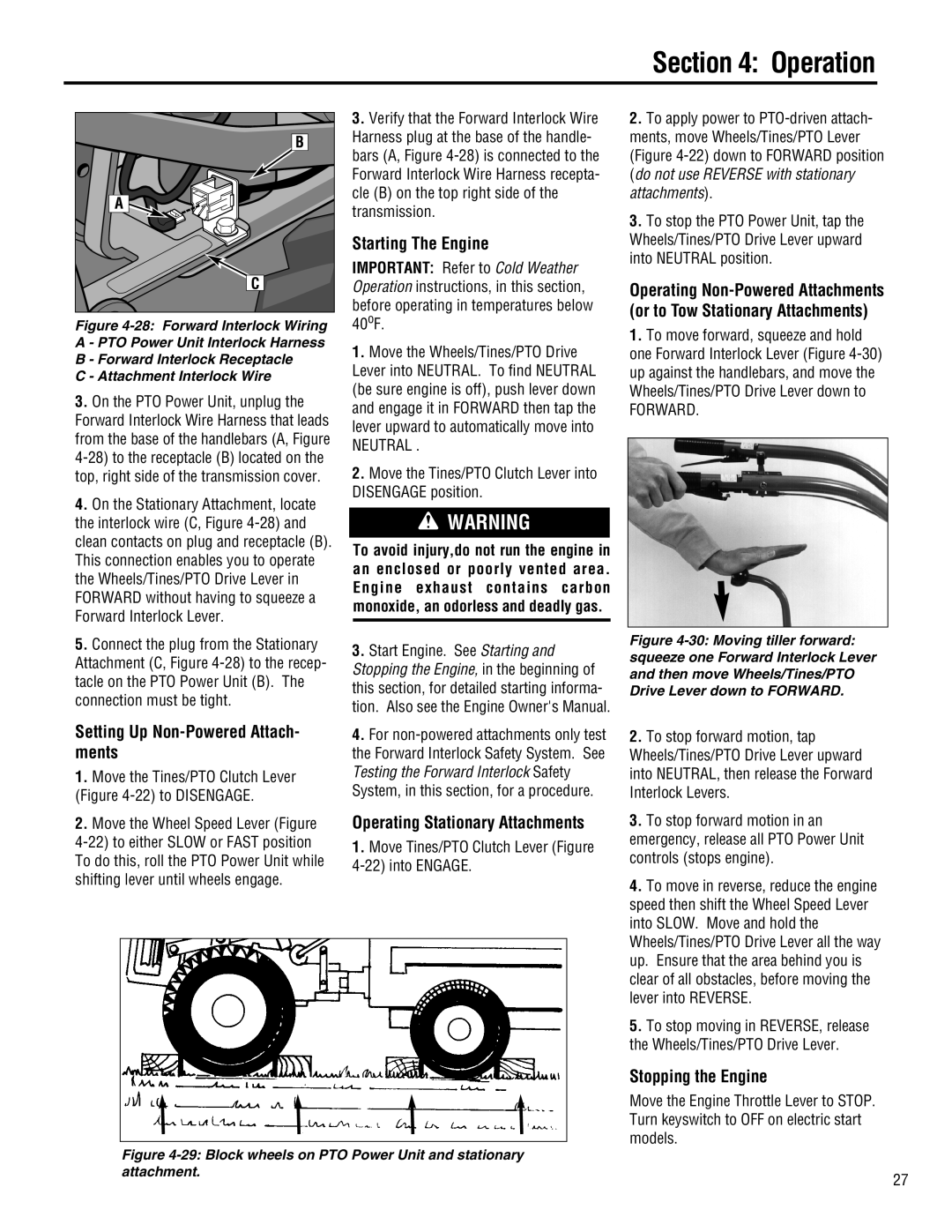

2.Remove dipstick from tine attachment (Figure

3.Slowly add gear oil in the dipstick hole. Add

4.Take dipstick readings frequently. Stop when oil reaches “Cold” range marking on dipstick. Replace dipstick securely.

Draining and Filling the Tine

Attachment Transmission

1.The tine attachment transmission is not equipped with an oil drain plug. To drain just a small amount of gear oil, remove the dipstick and tilt the attach- ment forward (first uncoupling it from the Power Unit).

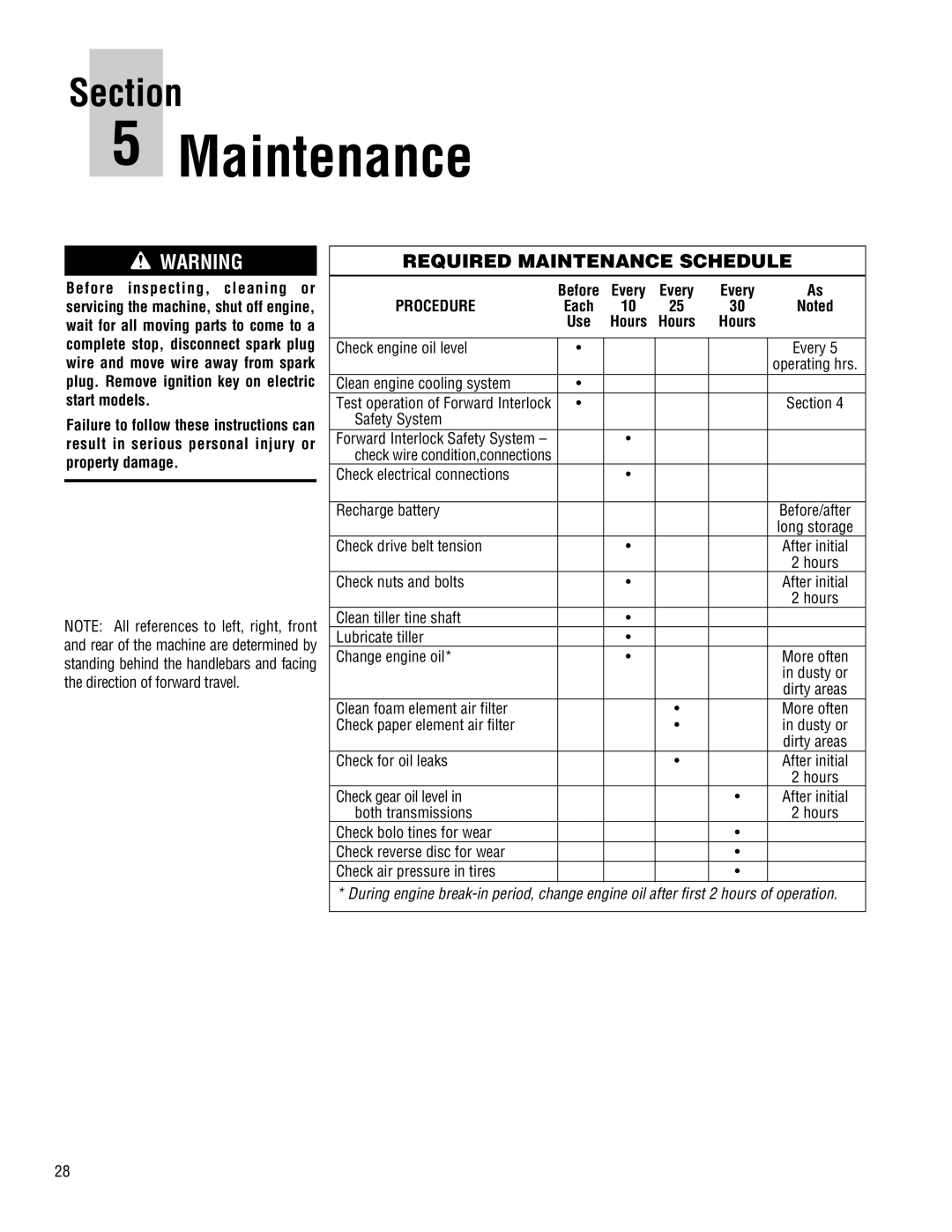

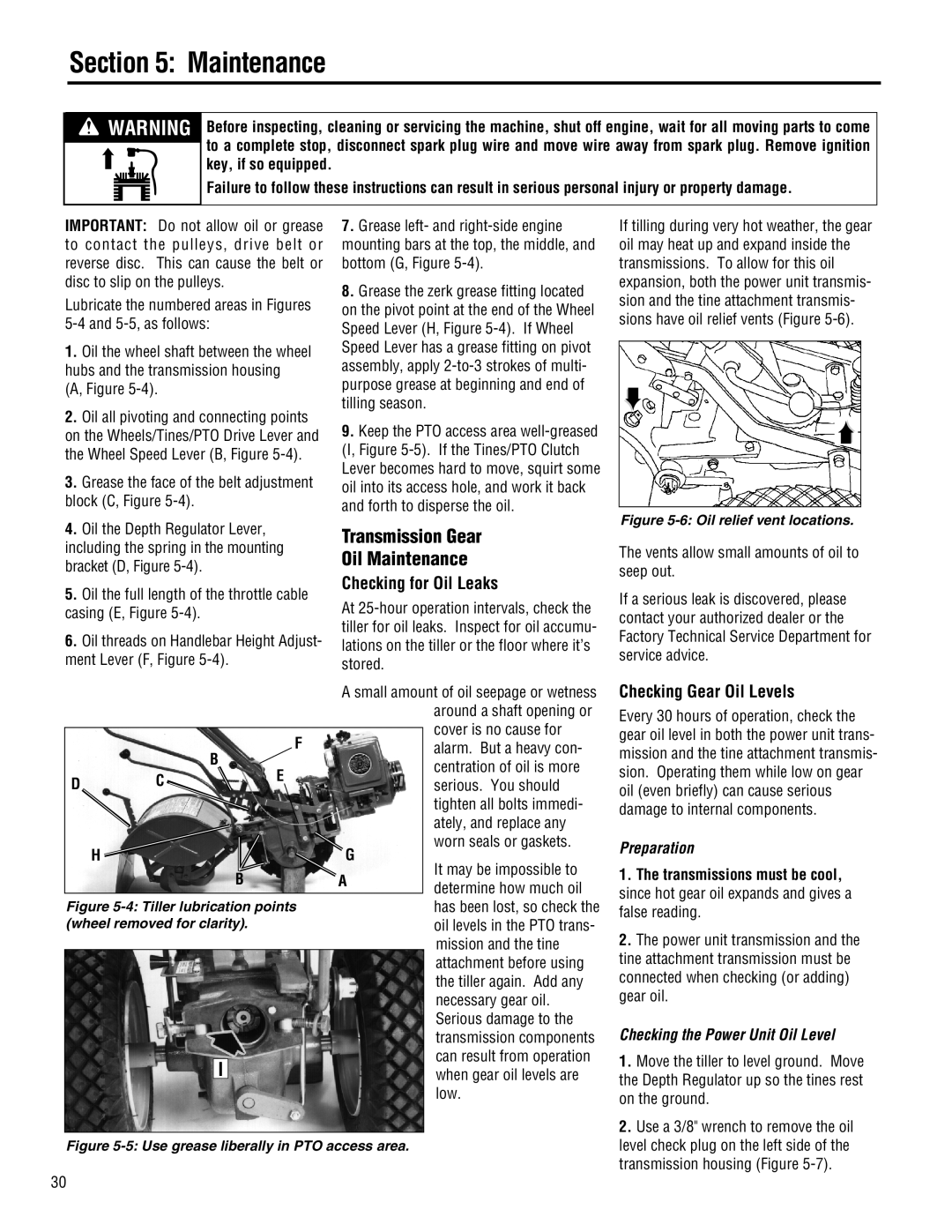

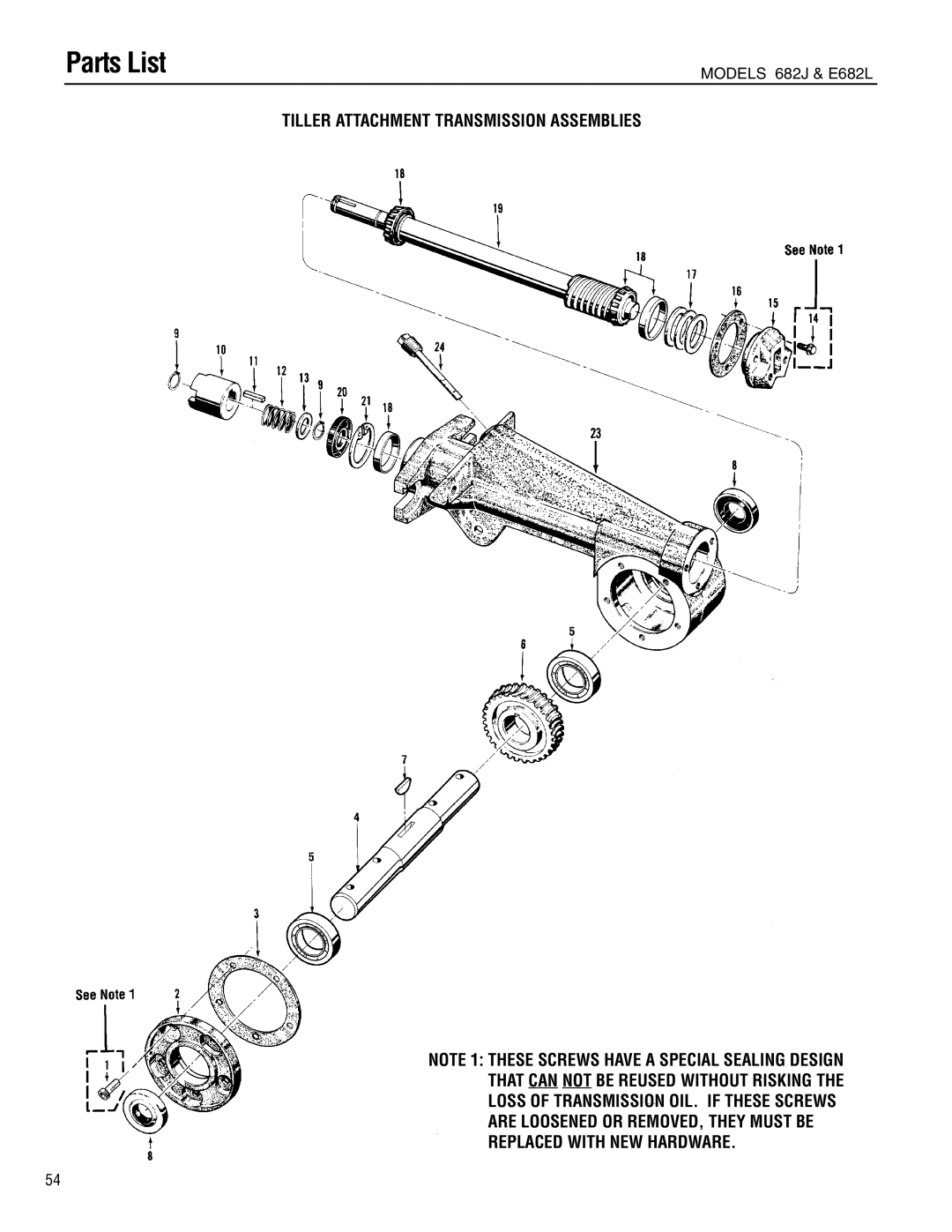

2.For complete drainage, remove the left- side tine assembly (refer to Bolo Tine Maintenance for instructions), then remove just one of the lower screws from the tiller housing cover (Figure

➧

Figure

NOTE: If you find a plastic washer on the cover screw you remove, discard the washer. There is no need to install a replacement washer.

3.Once all gear oil has drained, reinstall the housing cover screw securely (first coat its threads with

4.Be certain to refill the transmission with the correct amount of gear oil before

operating the tiller again.

32