MODEL | SECTION 2.0 |

| INSTALLATION |

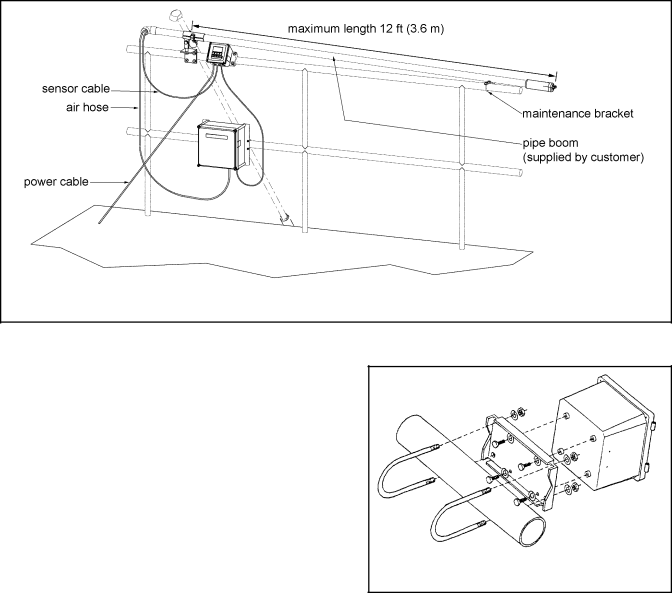

FIGURE 2-1. Suggested arrangement of handrail mounting assembly, maintenance clamp,

air compressor enclosure, and 54eA analyzer.

2.2.2 Installing the analyzer

When used in Model

2.2.3 Installing the air compressor enclosure

The air compressor is in a NEMA 4X fiberglass enclosure. Figure

1.Locate the enclosure within 25 ft (7.6 m) of the sensor.

2.Be sure the ambient temperature is between 5 and 122°F

2.2.4 Installing the handrail mounting assembly

FIGURE 2-2. Pipe Mounting

The handrail mounting assembly (PN

2.2.5 Assembling the pipe and pipe clamp

Slide the PVC pipe boom through the handrail mounting pipe clamp. Tighten the bolt to keep the clamp from sliding off. Use

8