W1772/W1773 37" Drum Sander

—If the difference between the two measurements at each end is more than 1⁄8", continue to the next step.

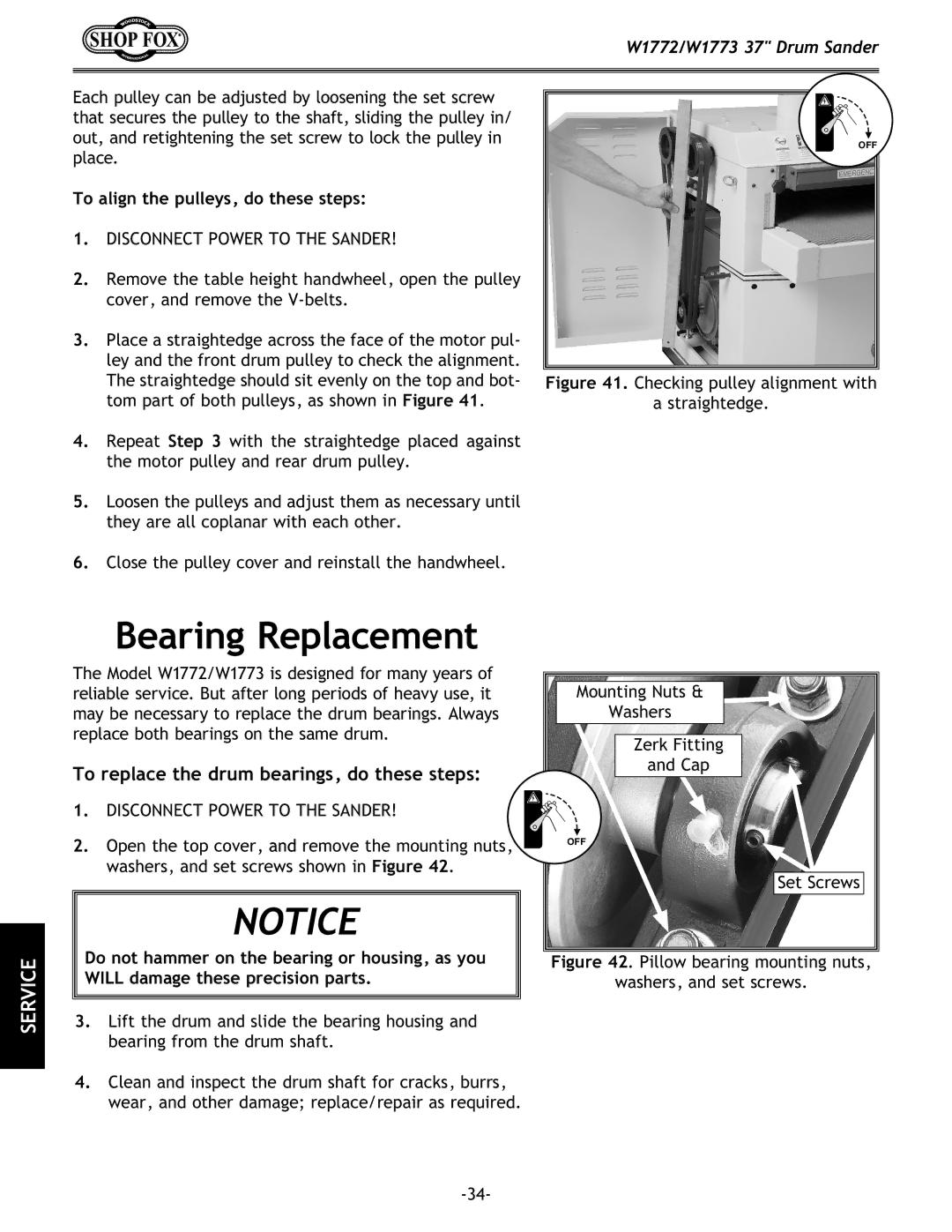

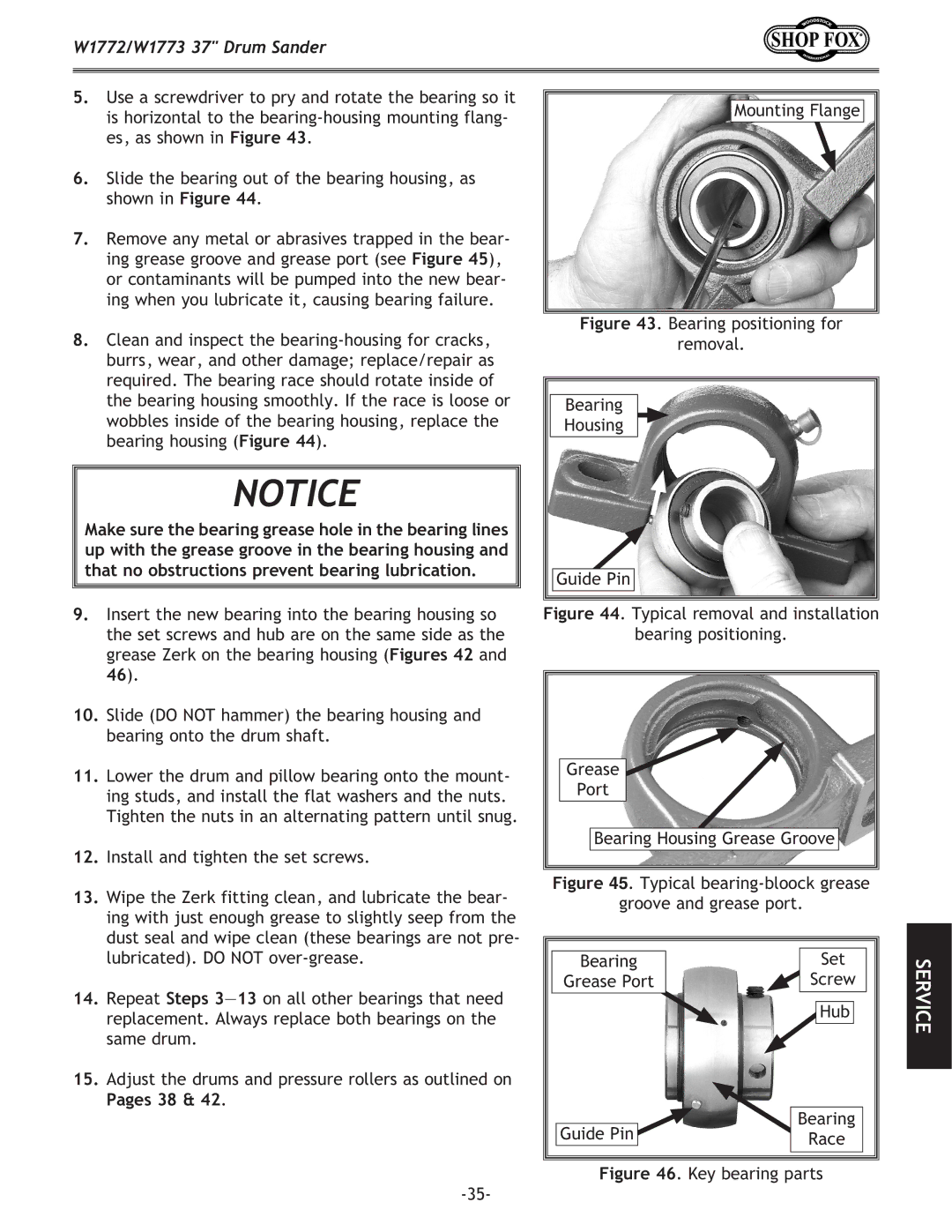

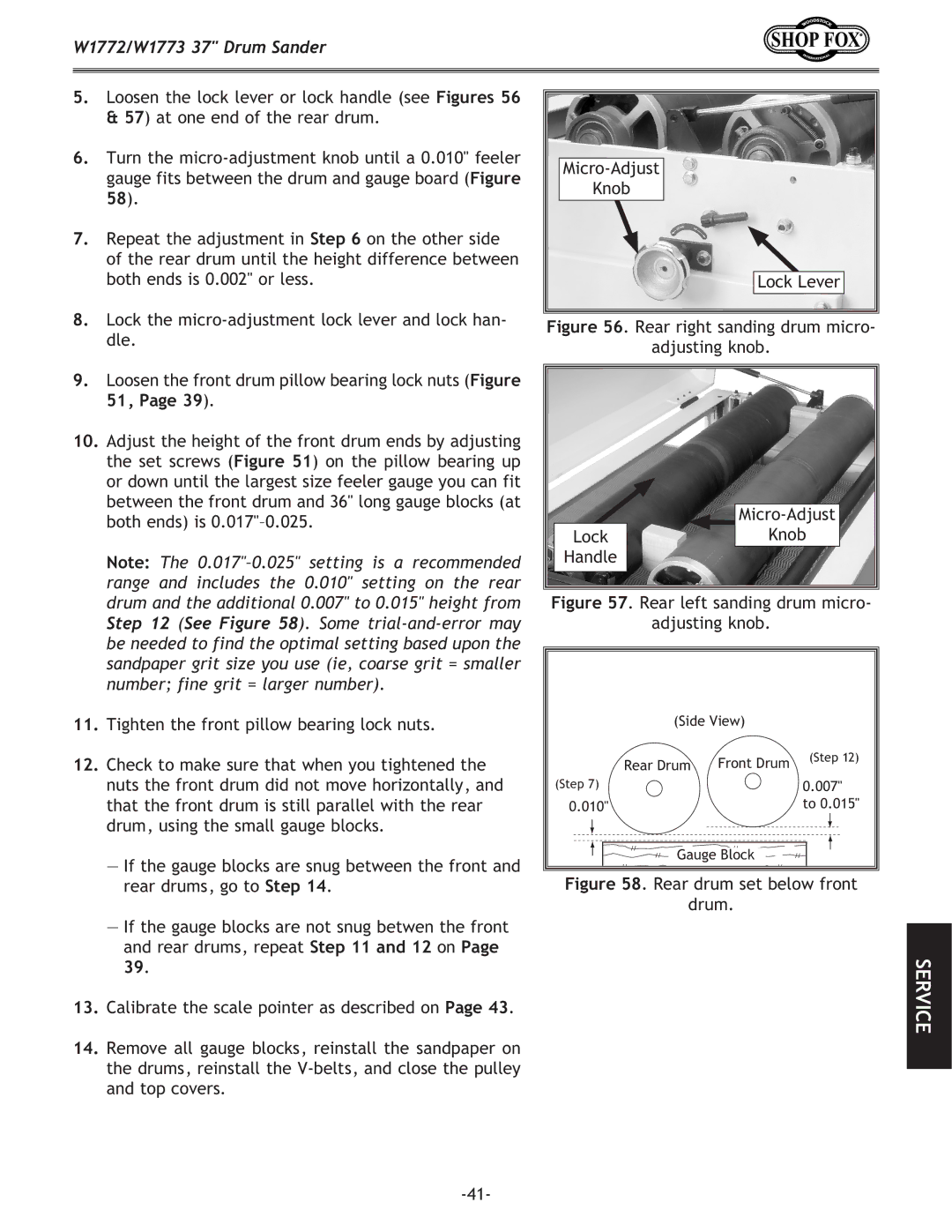

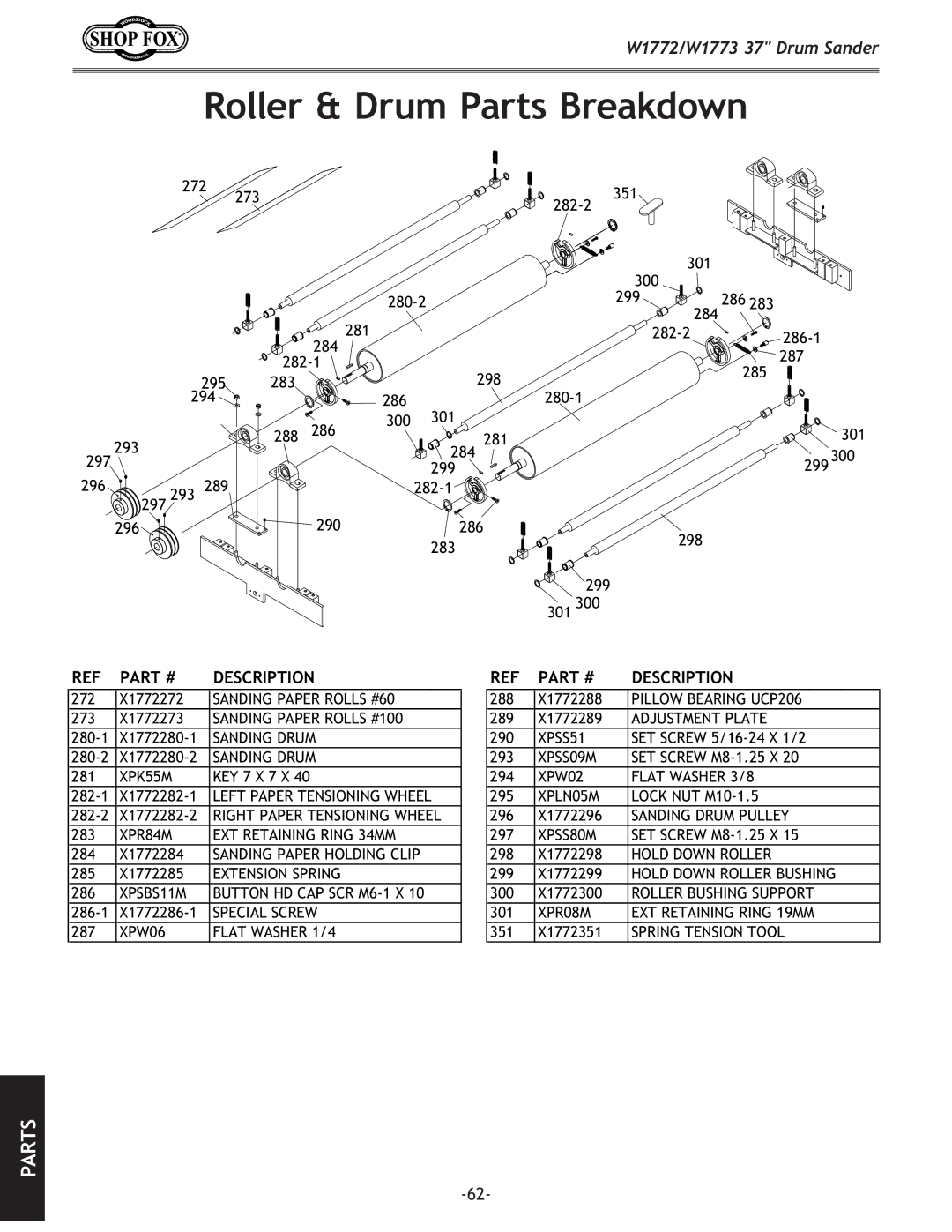

6.Loosen the rear drum pillow bearing lock nuts, shown in Figure 51.

7.Move one end of the drum forward or backward as needed in the slotted holes until the distance between the rear upper frame angle and drum is within 1⁄8" at each end, then tighten the rear drum pillow bearing lock nuts.

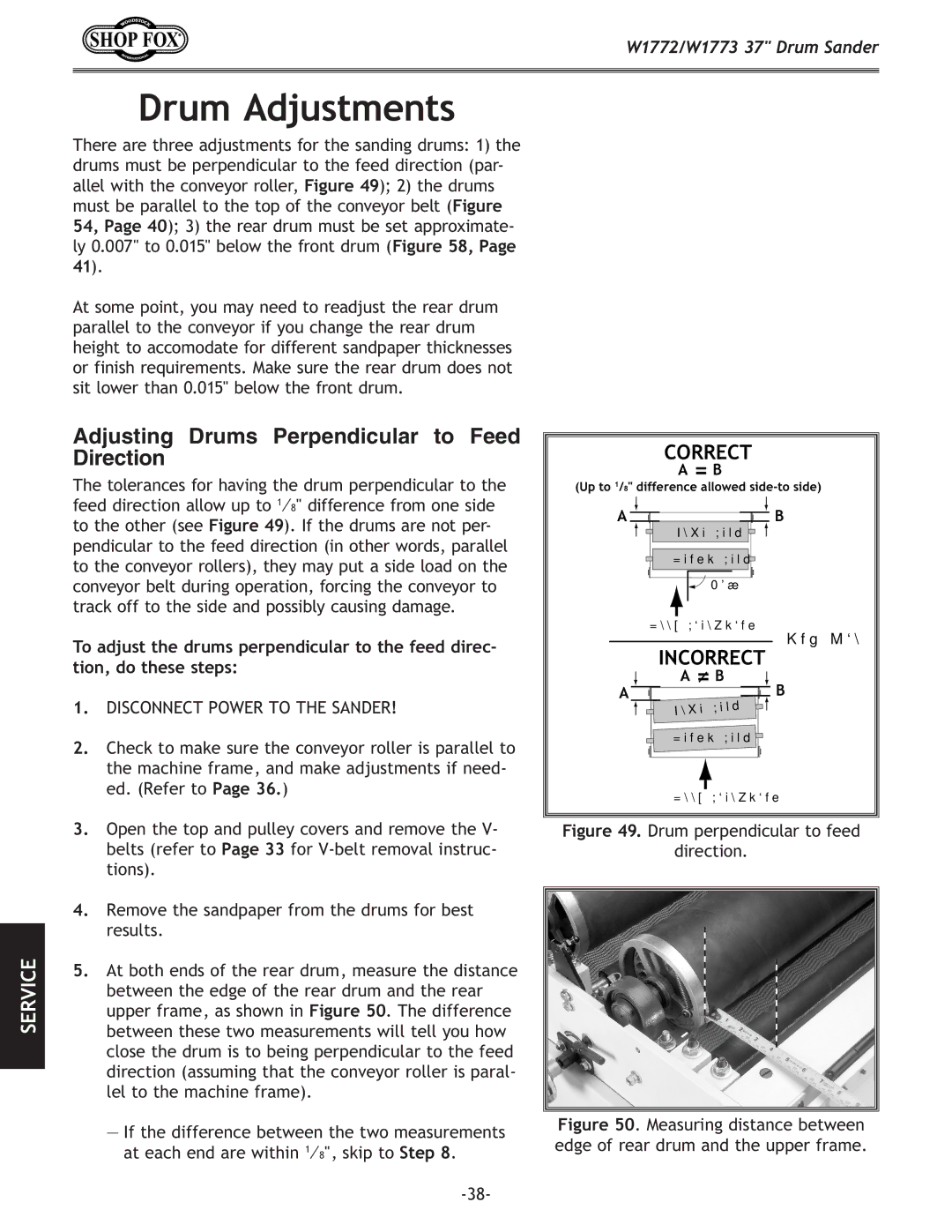

8.Measure the distance between the rear and front drum, as shown in Figure 52, on both sides.

—If the difference between the two measurements at each is equal or are within 1⁄8", skip to Step 13.

—If the difference between the two measurements at each end is more than 1⁄8", continue to the next step .

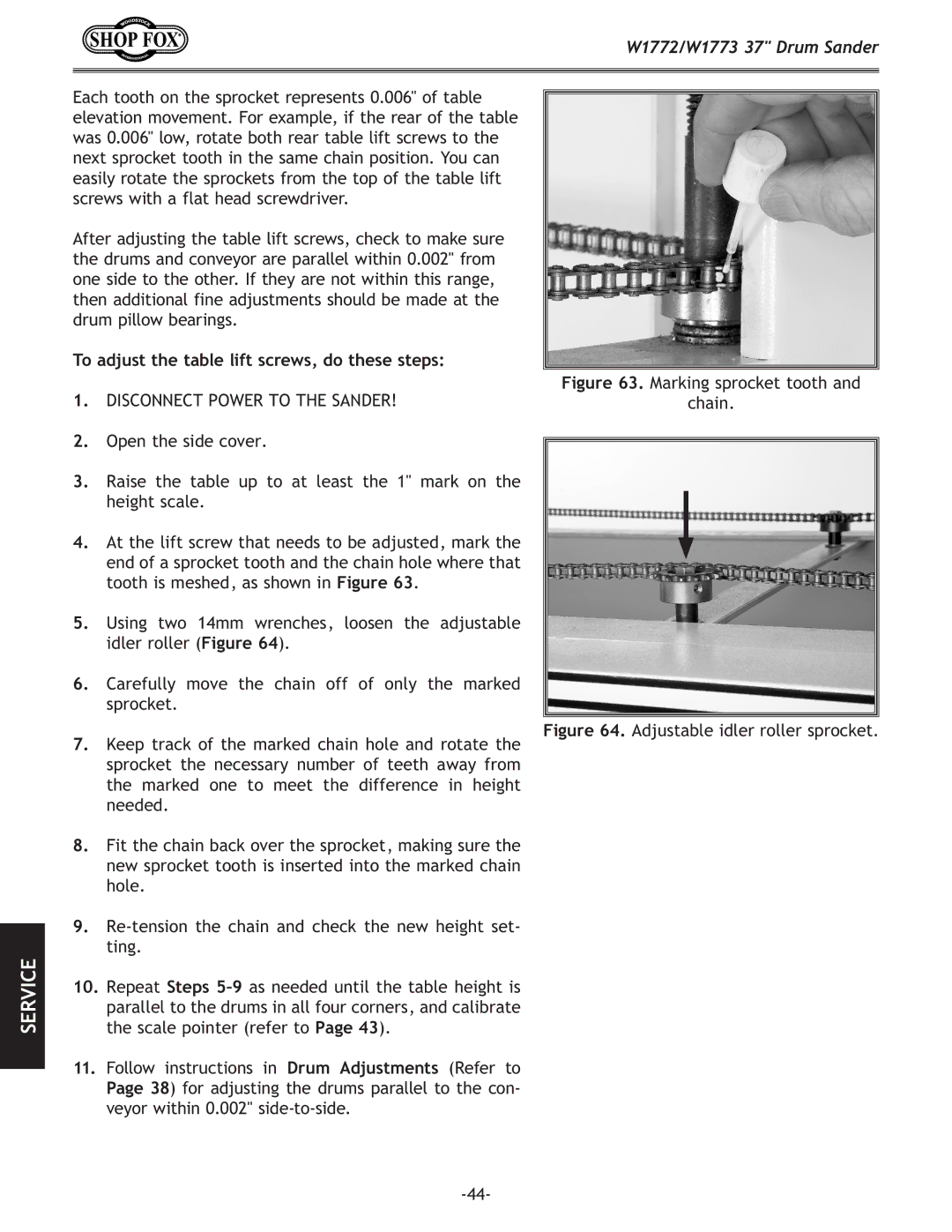

9.Make two gauge blocks the same width as your mea- surement in Step 8.

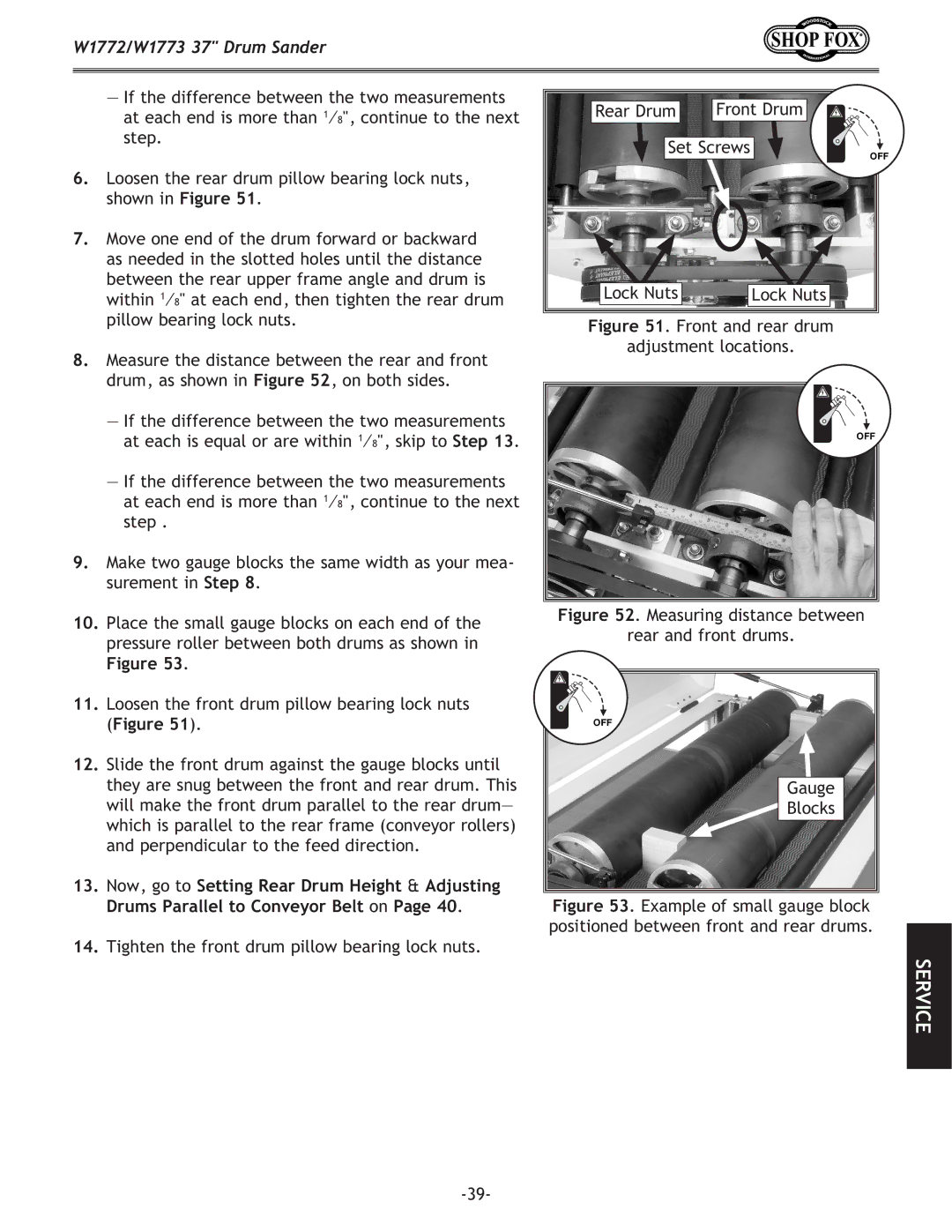

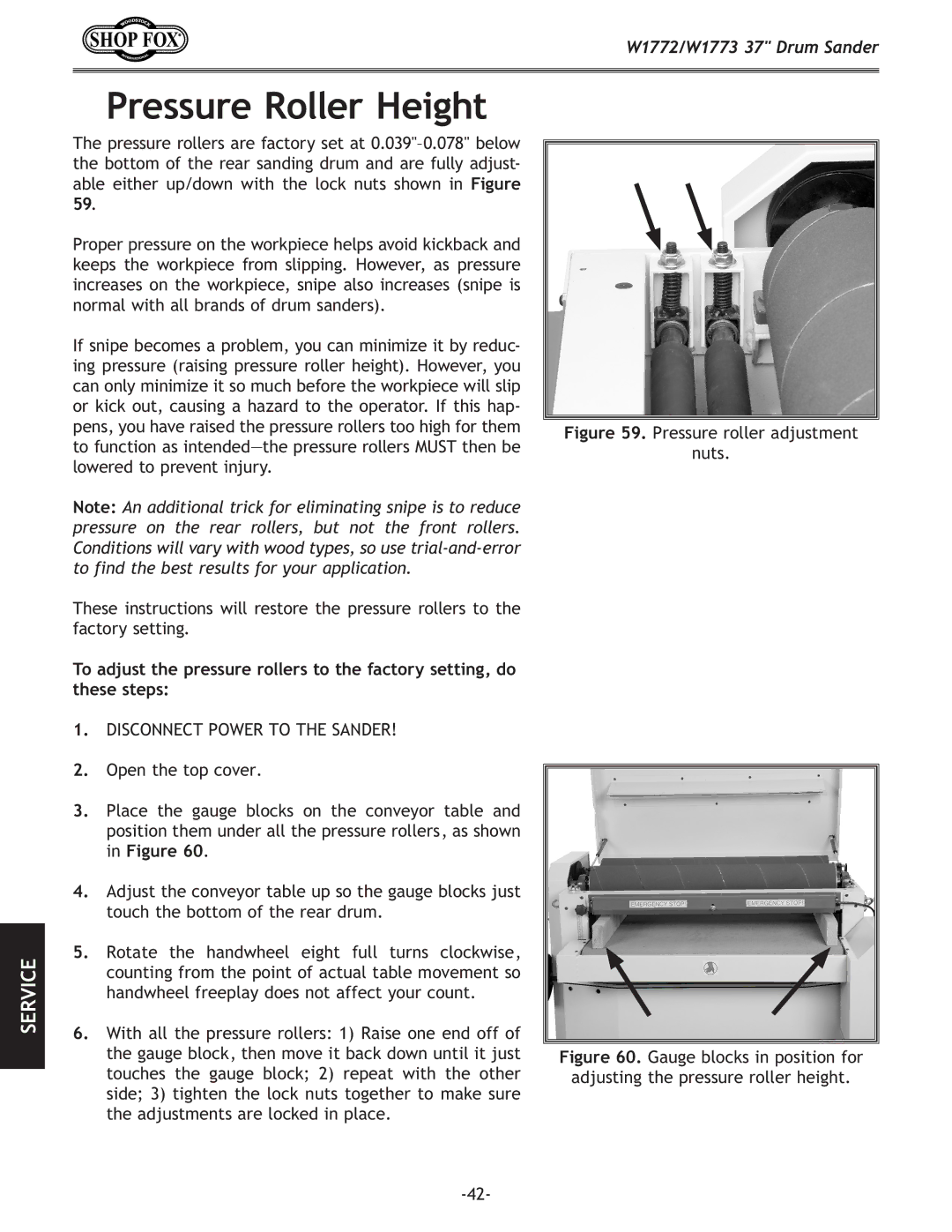

10.Place the small gauge blocks on each end of the pressure roller between both drums as shown in

Figure 53.

11.Loosen the front drum pillow bearing lock nuts (Figure 51).

12.Slide the front drum against the gauge blocks until they are snug between the front and rear drum. This will make the front drum parallel to the rear drum— which is parallel to the rear frame (conveyor rollers) and perpendicular to the feed direction.

13.Now, go to Setting Rear Drum Height & Adjusting Drums Parallel to Conveyor Belt on Page 40.

14.Tighten the front drum pillow bearing lock nuts.

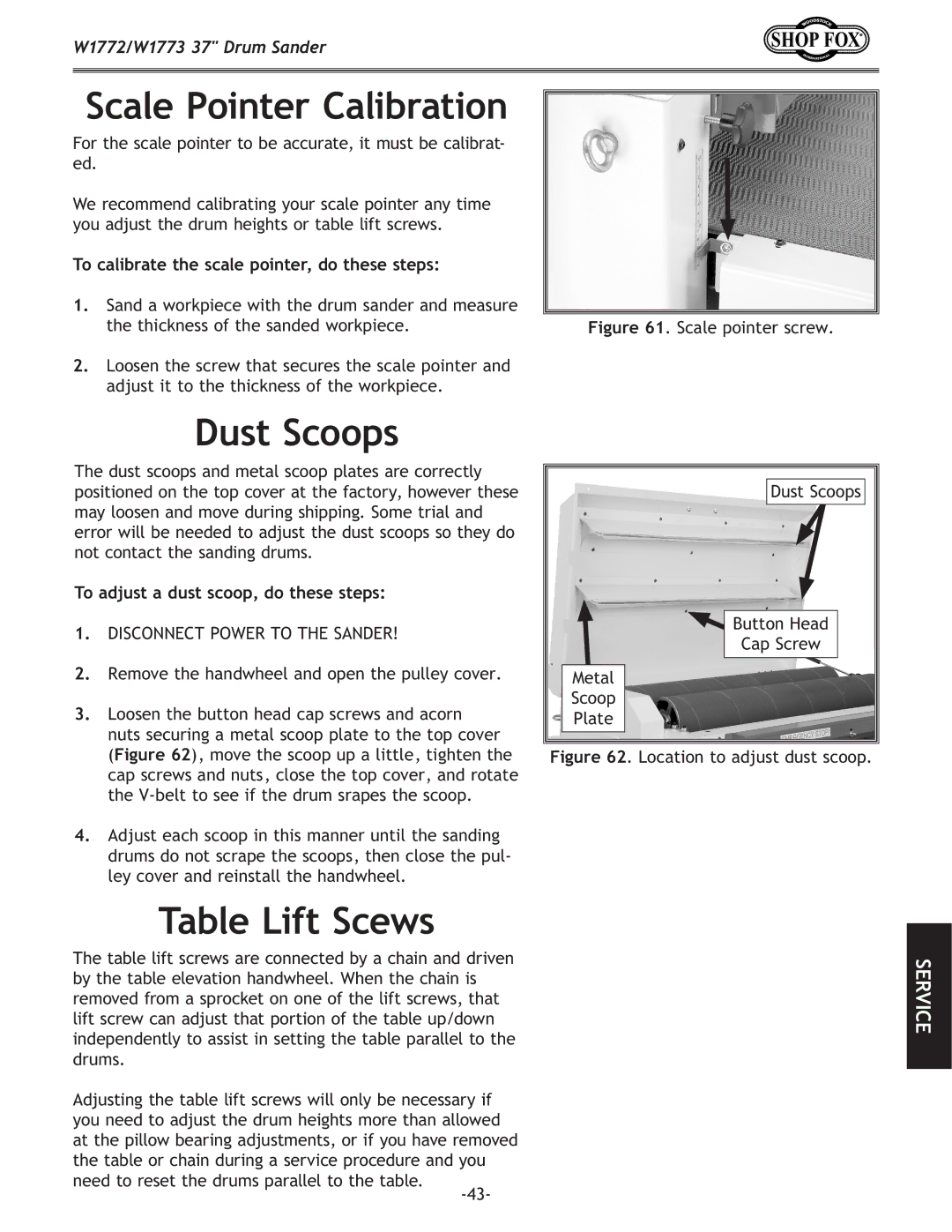

Rear Drum | Front Drum |

|

Set Screws | OFF | |

|

| |

Lock Nuts | Lock Nuts |

|

Figure 51. Front and rear drum

adjustment locations.

OFF

Figure 52. Measuring distance between

rear and front drums.

OFF

Gauge

Blocks